Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

- Recommended Applications

- The rapid cure time of Crystic® 1124PA/PAX makes it particularly suitable for the manufacture of flat panels, since it cures quickly even in thin laminates, allowing fast production rates. It is non-thixotropic to allow rapid wetting and impregnation of reinforcements on flat panel molds, and has been specially formulated to aid in the elimination of air. It has good adhesion to Crystic® ScottBond 102PAW, allowing sandwich panels to be made with little risk of delamination.

- Crystic® 1124PA/PAX can be used without modification in most types of spray equipment. Its low viscosity allows lower spray pressures to be used, reducing overspray. It requires only the addition of catalyst to start the curing reaction and is therefore ideal for long production runs under controlled workshop conditions.

- Crystic® 1124PA/PAX has been formulated to give a tough resilient laminate. It can be used with confidence in the construction of GRP skins for flat sandwich panel manufacture.

- Crystic® 1124PA is also available pigmented white as Crystic® 1124PA White.

- Formulation Guidelines

Crystic® 1124PA/PAX is formulated for room temperature curing applications. It requires only addition of the correct amount of catalyst to start the curing reaction. The recommended formulation is given in Table 1:

Table 1

Component Parts by weight Crystic 1124PA 100 Andonox® KP9 or Andonox® KP9 1.0 - 3.0 The catalyst must be stirred thoroughly into the resin shortly before use. Curing should not be carried out at temperatures below 15°C. Scott Bader (Pty) Ltd. will not be liable for problems caused by use at lower temperatures than recommended. The resin must be allowed to attain workshop temperature (15-30°C) before being formulated for use.

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Acid Value | 18.5 | mg KOH/g | — |

| Viscosity (at 25°C, Brookfield RVT, 100 rpm) | 270 | Centipoise | — |

| Stability (at 20°C) | 3 | Months | — |

| Specific Gravity (at 25°C) | 1.056 | — | — |

| Volatile Content | 40 | % | — |

| Gel Time (at 25°C, using 2% Andonox® KP9 catalyst) | 7 | Minutes | — |

Technical Details & Test Data

- VERSIONS

Crystic® 1124PAX is a faster curing version of Crystic® 1124PA, designed for use in continuous laminating processes.

- Gel time adjustment

The temperature and the amount of Norox® KP9 or Norox® PD40 control the gel time of the resin formulation and can be approximately determined from table 2.

Catalyst type Andonox® KP9 Andonox® PD40 Catalyst addition 1.0% 2.0% 3.0% 1.0% 2.0% 3.0% Temperature 15°C 12 7 combination not recommended combination not recommended combination not recommended 25°C 9 7 combination not recommended 20 16 14 35°C 6 5 combination not recommended 9 8 7 - Crystic® 1124PA/PAX is formulated for use between 15°C and 30°C. It is recommended that workshop temperatures be maintained within this range.

- In hot summer conditions, Crystic® 1124PA/PAX may give too short a geltime for adequate potlife. If this is the case when using Catalyst M, do not use less than 1% catalyst as this will lead to slow cure even if the geltime is acceptable. Rather use Norox® KP-925H, or better still Norox® PD40. Both will slow down the geltime of the resin, and with an increase in speed and completeness of cure. In fact, under normal workshop conditions, Norox® PD40 gives longer potlife than other catalysts with this resin, whilst increasing the speed with which sufficient cure for demolding is reached.

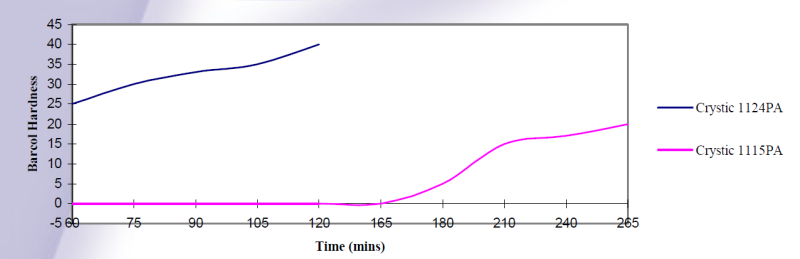

- Crystic® 1124PA/PAX is designed to give faster cure than a general purpose polyester resin when used to make large, thin flat laminates. It should be sprayed, spread or poured over the mold surface as quickly as possible after catalyzing, as once it is in a thin layer its reaction speed will slow appreciably. Once the laminate has been consolidated, cure takes place at a faster rate than a general purpose resin, as shown in fig. 1.

Fig. 1. Barcol Hardness development over time with Crystic 1124PA compared to that of a medium reactivity orthophthalic unsaturated polyester resin. Both are catalyzed with 2% Andonox® KP9.

Barcol Hardness development over time - fast cure resin (Crystic® 1124PA) and GP resin

- At temperatures below 15ï‚°C, the curing reaction can be so slow that there is a high probability of undercure of the resin, even with over 3% Norox® KP9 or Norox® KP9. Do not use more than 3% catalyst as that will not speed up the geltime appreciably or result in a faster cure; in fact it can further retard the cure. Rather warm up the resin and working area so that it is above 15°C. Low workshop temperature is often a cause of poor surface finish of flat panel skins, since if the cure is retarded, it can continue after the skins have been demolded. This can cause fiber pattern to be reproduced on the gelcoated side of the skin. It is advisable to use infrared heaters to ensure that the mold is at the correct temperature

- Pigments and Fillers

Crystic® 1124PA/PAX may be pigmented with up to 5 percent of Scott Bader pigment paste, although lesser amounts are normally sufficient in a laminating resin. Pigment pastes and fillers should be used with caution, as they are likely to have a significant effect on the storage stability, geltime and cure of the resin system, and the physical strength properties of the final product.

- Post Curing

It is usually impractical to post cure flat panel skins due to their size. The importance of thorough cure to flat panel skins is that if they are demoulded whilst undercured, cure continues whilst there is no vacuum between the gelcoat and the mold. The resultant shrinkage of the resin around the glass fibers causes the glass fiber pattern to appear in relief on the gelcoat surface. This reduces the attractiveness of the finish. The fast curing behavior of Crystic® 1124PA/PAX allows it to reach sufficient cure to be demoulded in 2 hours at 25ºC in a 450g/m² chopped strand mat laminate. At temperatures below this, more time has to be allowed. A convenient way to speed up cure in cold conditions is to use infrared lamps over the mold.

Packaging & Availability

- Packaging Type

- Packaging

Crystic 1124PA is supplied in 25kg and 225 kg steel containers, and in 1125kg returnable intermediate bulk containers.

Storage & Handling

- Storage

- Crystic® 1124PA/PAX should be stored in the dark in suitable closed containers. It is recommended that the storage temperature should be less than 20°C where practical, but should not exceed 30°C. Ideally, containers should be opened only immediately prior to use. Where they have to be stored outside, it is recommended that drums be kept in a horizontal position to avoid the possible ingress of water.