Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Applications

- Composites End Use

- Formulation Guidelines

Crystic195 should be allowed to attain workshop temperature (18ºC - 20ºC) before use. It requires the addition of a catalyst and an accelerator to start the curing reaction. The recommended catalyst is Catalyst M (or Butanox M50) which should be added at 2% into the resin. The catalyst must be thoroughly dispersed in the resin, and this mix will remain usable for approximately 24 hours at workshop temperature (18ºC - 20ºC). Shortly before use, the correct amount of Accelerator E should be stirred into the catalyzed resin. N.B Catalyst and accelerator must not be mixed together, directly, as they can react with explosive violence.

- Pot Life

The amount of Accelerator E can be approximately determined from the table below.

Parts of Accelerator E to

100 Parts of Catalyzed Resin1.0 2.0 3.0 4.0 Pot life in Minutes at 15ºC 120 80 58 45 Pot life in Minutes at 20ºC 80 55 40 30 Pot life in Minutes at 25ºC 60 42 30 25 The resin and the workshop should be at, or above, 15ºC before curing is carried out.

Properties

- Color

- Typical Liquid Resin Properties

- Laminate properties

- Resin Properties - Unfilled Casting (Cured)

- Note

* Curing Schedule - 24 hrs at 20ºC, 3 hrs at 80ºC

† Curing Schedule - 24 hrs at 20ºC, 5 hrs at 80ºC, 3 hrs at 120ºC

** Made with 4 layers 450g/m2 PB CSM Curing schedule - 24hrs at 20ºC, 16hrs at 40ºC

| Value | Units | Test Method / Conditions | |

| Viscosity (at 25°C, 92.4 s⁻¹) | 1.7 | Poise | BS 2782 |

| Specific Gravity (at 25°C) | 1.12 | — | BS 2782 |

| Volatile Content | 40 | % | BS 2782 |

| Acid Value | 31 | mg KOH/g | BS 2782 |

| Stability (at 20°C) | 6 | Months | BS 2782 |

| Gel Time (at 25°C, using 2% Catalyst M) | 25 | Minutes | BS 2782 |

| Gel Time (at 25°C, using 4% Accelerator E) | 25 | Minutes | BS 2782 |

| Value | Units | Test Method / Conditions | |

| Glass Content** | 27 | % | BS 2782 |

| Tensile Strength** | 98 | MPa | BS 2782 |

| Tensile Modulus** | 7062 | MPa | BS 2782 |

| Elongation (at break)** | 1.8 | % | BS 2782 |

| Flexural Strength** | 170 | MPa | BS 2782 |

| Flexural Modulus** | 5480 | MPa | BS 2782 |

| Value | Units | Test Method / Conditions | |

| Barcol Hardness (Model GYZ 934-1)* | 48 | — | BS 2782 |

| Deflection Temperature (under load 1.80 MPa)†* | 68 | ºC | BS 2782 |

| Water Absorption (24h, at 23°C)* | 20 | mg | BS 2782 |

| Tensile Strength* | 47 | MPa | BS 2782 |

| Tensile Modulus* | 4600 | MPa | BS 2782 |

| Elongation (at break)* | 1.2 | % | BS 2782 |

| Specific Gravity (at 25°C)* | 1.24 | — | BS 2782 |

| Volumetric Shrinkage* | 9.7 | % | BS 2782 |

| Refractive Index (n 25/d)* | 1.548 | — | BS 2782 |

Technical Details & Test Data

- Weather Resistance and Light Transmission

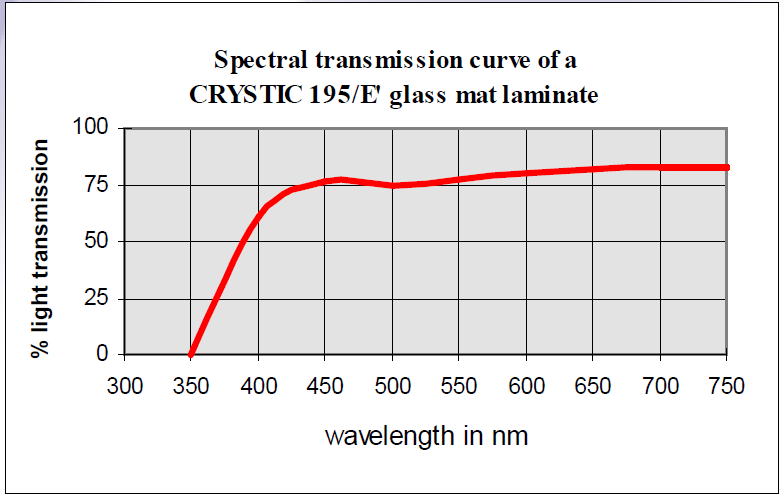

To ensure maximum light transmission, laminates made with Crystic 195 should have a resin to glass ratio of at least 3:1. The spectral transmission curve shown below is that of a typical, fully cured, Crystic 195 laminate.

For optimum weather resistance and durability, laminates must be fully cured. After molding, laminates should be allowed to mature at 20ºC for at least three weeks before being put into service. Post curing at elevated temperatures is not recommended.

- Additives

Crystic195 may be colored by the addition of small quantities of light stable translucent tints. Tests should be made by the user, to ensure even color distribution.

Packaging & Availability

- Packaging Type

- Packaging

- Crystic®195 is supplied in 25kg and 200kg containers. Bulk supplies can be delivered by road tanker.

Storage & Handling

- Storage

- Crystic®195 should be stored in the dark in suitable closed containers. It is recommended that the storage temperature should be less than 20°C where practical, but should not exceed 30°C. Ideally, containers should be opened only immediately prior to use. Where they have to be stored outside, it is recommended that they are kept in a horizontal position to avoid the possible ingress of water.