Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Ingredient Origin

- Food Ingredients Functions

- Pharma & Nutraceuticals Functions

- Ingredients

- Sugar

Features & Benefits

- Labeling Claims

- Food Ingredients Features

- Benefits

- Pure and natural

- Dissolves rapidly, homogeneously

- High filterability

Applications & Uses

- Applications

- Sugar Processing

Harvest Time

Sugar beet harvesting begins in September, “the campaign”. We take samples from each load of beet delivery to determine e.g. Sugar content and to analyze the amount of soil left on the beets. Once the beets are offloaded they are thoroughly washed and are sent directly to the processing line or to the storage facility.

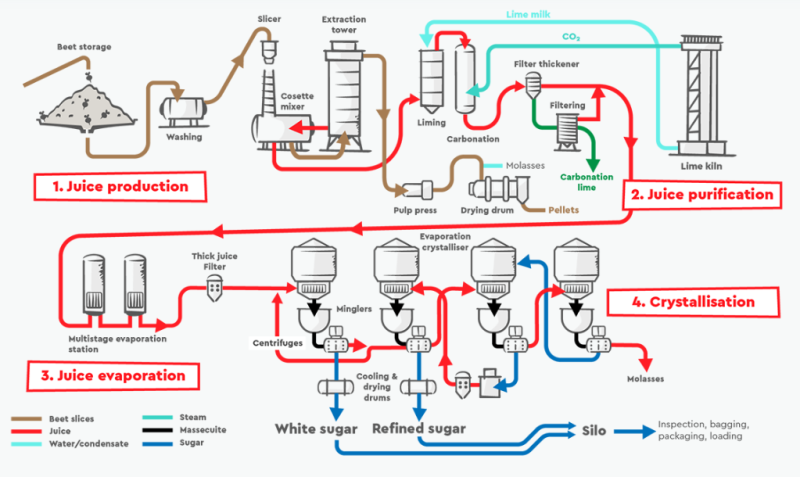

Juice Production

The beets are sliced into thin strips known as cossettes, pre-heated in a cossette scalder and are then sent to an extraction tower. Water at 70°C is poured through the device to extract the sugar and produce raw juice. The used cossettes are dried by means of screw presses and hot air.

Juice Purification

A lime kiln is used to produce the natural substances lime and carbon dioxide, which are added sequentially to the raw juice to bind and precipitate out the non-sugar impurities. A clear, thin juice with a sugar content of approximately sixteen percent remains.

Evaporation

The thin juice is concentrated by heating to make a thick golden-brown juice with a sugar content of about sixty-seven percent.

Crystallization

The thick juice is boiled until crystals are formed, which are a glowing golden color because they are covered in syrup. The syrup is separated from the crystals in a centrifuge. Hot water is used to rinse off any residual syrup. The remaining sugar crystals are clear as glass, and the light refracted from them is white as snow. The sugar is dissolved and re-crystallized to produce refined sugar – sugar that is extremely pure.

Converting

The finished sugar is dried, cooled and stored in silos, and is subsequently withdrawn and further processed or packed. Over eighty percent is sold for industrial use with the balance sold to retail.

Properties

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Organic Quality

White Sugar is also available in certified-organic quality. Our organic beet sugar is available with the following organic certifications: EU Bio, Naturland, BioSuisse and Bioland.

- Available Grain Sizes

We offer these products in a wide variety of different grain sizes that provide unique functional benefits which make them particularly suitable for specific applications. Our granulated white sugars are available in five grain sizes: Standard, Coarse, Medium, Fine, Extra Fine. We can also supply additional grain sizes upon request.

Type of designation Symbol Mean aperture (in mm)Standard S 0.40 – 1.00 Coarse C 1.00 – 1.60 Medium M 0.60 – 1.00 Fine F 0.40 – 0.65 Extra Fine XF 0.20 – 0.40 - Packaging

Packaging type Packaging unit (in kg)PE Bag 20, 25 Paper Bag 20, 25 Big Bag 1000 Bulk

Storage & Handling

- Storage

Granulated White Sugar has no best-before date but should be stored above 10°C, below a relative humidity of around 65 %, and kept away from odorous materials. Under these conditions, our Granulated White Sugars will keep their specific properties and are indefinitely storable.