- Reinforcement Material:Glass Fibers

- Reinforcement Form:Multiaxial Fabric, Non Crimp Fabrics

- Processing Methods:Vacuum Bagging, Resin Transfer Molding (RTM), Hand Lay-up

- Features:Corrosion Resistant, High Strength, High Stiffness, Corrosion Resistance

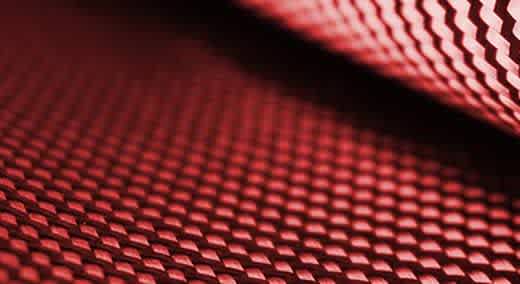

E-Fiberglass Welf Triaxial can be used in a variety of applications in the automotive, aerospace, construction, corrosive, industrial and marine industries. NCF is a composite reinforcing fabric in which fibers are organized into layers of plies of variable weight and orientation. The layers are stitched together. The result is a range of engineered fabrics with predictable, repeatable properties for the composite industry. Triaxial Transverse (Weft Triaxial) Non-Crimp Fabrics are ideal for applications that require a combination of high transverse and shear strength and stiffness, and some longitudinal strength. The combination of straight, non-woven fibers and high glass volume fractions give superior properties at lower weight. This triaxial product is suitable for hand lay-up, vacuum bagging of relatively flat components (minimum curvature radius approximately 15mm), vacuum injection and other RTM-processes.