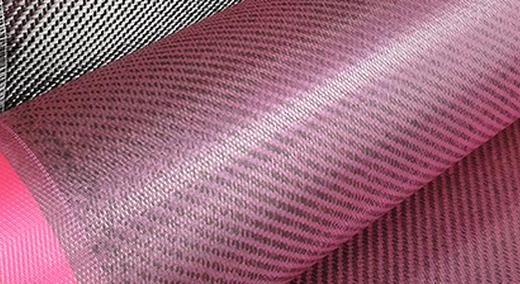

Prepregs & Molding Compounds

1,217 Products

Discover materials like prepregs, laminates & molding compounds for designing parts used in automotive, building, electrical parts & other industrial applications on Knowde.

Epoxy Resins & CompoundsThermoset PolyesterPhenolic CompoundPhenol Formaldehyde (PF)Polytetrafluoroethylene (PTFE)Glass FibersCarbon FibersMineralAramid (Kevlar)CottonTanksHousingsCasesPipesStructural ComponentsCompression MoldingPrepreg ProcessingInjection MoldingVacuum BaggingOut of Autoclave Prepreg