Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Convoluted Tubes for Automotive Application Data

Details

Arnitel® convoluted tubing is used in class-D and class-E cable trees. The primary purpose is usage in high temperature areas of the car.

Benefits

- Arnitel® offers a high continuous use temperature (>150C)

- Arnitel® is easily extrudable into low wall thickness

- Arnitel® has flame retardant grades available

- Brake Tubing With Arnitel® CM622 Application Data

Benefits

- Arnitel® TPC allows for light weight solutions (75% lighter compared to rubber)

- Arnitel® TPC allows for cost effective solutions (up to 50% lower system costs than rubber)

- Arnitel® TPC allows for sustainable solutions (compared to PA12, Arnitel is a plasticizer free solution)

- Arnitel® TPC allows for reliable solutions due to its peak temperatures resistance up to 180°C – 200°C and its good heat aging due to continuous use temperatures 120°C – 170°C

- Wire and Cable Insulation Application Data

Details

Arnitel® UM551 in use for convoluted tubes or cable protection under-the-bonnet.Benefits

- Arnitel® TPC allows for reliable solutions due its high temperature resistance (class T3 and T4, Class D (150°C) enabling thin and ultra thin wall designs, Class E (175°C) >20 mm2 thick and thin wall)

- Arnitel® TPC allows for cost effective solutions (up to 50% lower system costs versus ETFE/FEP, 40% weight down versus XL PO at similar costs)

- Arnitel® TPC allows for sustainable solutions due to availability of halogen free flameretardant grades

Properties

- Mechanical Properties

- Thermal Properties

- Other Properties

- Mechanical Properties (Die Cutting)

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Flexural Modulus | 270 | MPa | ISO 178 |

| Charpy Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | 5 | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (at -30°C) | 5 | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 208 | °C | ISO 11357-1/-3 |

| Glass Transition Temperature (at 10°C/min) | -10 | °C | ISO 11357-1/-2 |

| Vicat Softening Temperature (50°C/h 10N) | 190 | °C | ISO 306 |

| Vicat Softening Temperature (50°C/h 50N) | 90 | °C | ISO 306 |

| Value | Units | Test Method / Conditions | |

| Water Absorption in Water (at 23°C after 24h) | 0.22 | % | ISO 62 |

| Humidity Absorption | 0.1 | % | Sim. to ISO 62 |

| Density | 1270 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Stress at Break (normal) | 40 | MPa | ISO 527-1/-2 |

| Strain at Break (normal) | 640 | % | ISO 527-1/-2 |

| Tear Strength (normal) | 171 | kN/m | ISO 34-1; Method B |

| Tear Strength (parallel) | 191 | kN/m | ISO 34-1; Method B |

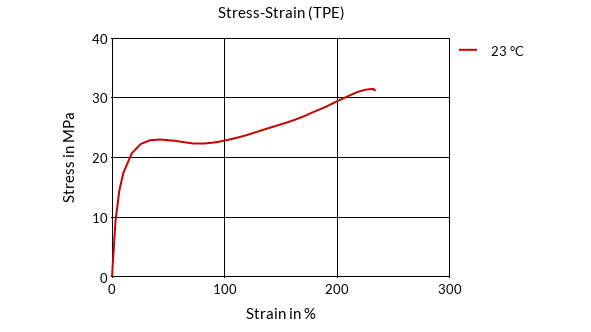

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 310 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 15 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 20 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 23 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 21 | MPa | ISO 527-1/-2 |

| Stress at Break | 33 | MPa | ISO 527-1/-2 |

| Strain at Break | >300 | % | ISO 527-1/-2 |

| Nominal Strain at Break | 520 | % | ISO 527-1/-2 |

| Compression Set Under Constant Strain (at 70°C) | 37 | % | ISO 815 |

| Shore A Hardness (3s) | 98 | — | ISO 868 |

| Shore A Hardness (15s) | 98 | — | ISO 868 |

| Shore D Hardness (3s) | 61 | — | ISO 868 |

| Shore D Hardness (15s) | 61 | — | ISO 868 |

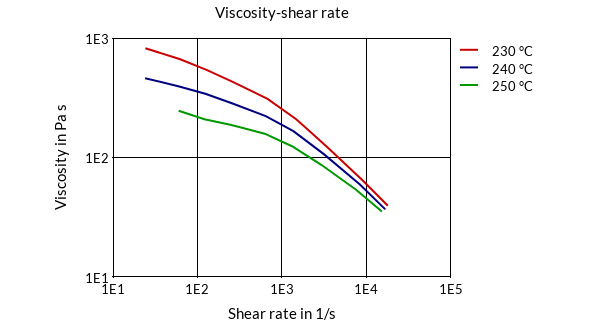

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 9 | cm³/10min | ISO 1133 |

Regulatory & Compliance

- Certifications & Compliance

- OEM Specifications

- OEM Standards

- Quality Standards

Technical Details & Test Data

- Chemical Resistance

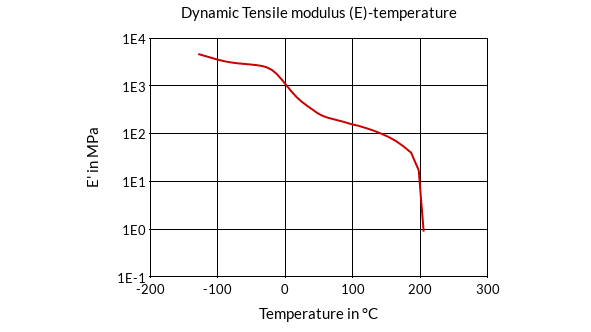

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Dynamic Tensile Modulus (E)-Temperature

- Stress-Strain (TPE)

- Viscosity-Shear Rate

Packaging & Availability

- Packaging Type