Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Smokable Sausage Casings Application Data

Details

Arnitel® ECO is bio-based material with up to 50% reduction in carbon footprint.Benefits

- Arnitel® TPC and Akulon® PA6 allow for reliable solutions since they yield excellent smoke penetration leading to great taste and sausage structure and high quality

- Arnitel® TPC and Akulon® PA6 allow for sustainable solutions, since they are free of substances of hazardous concerns and thus more environmentally friendly than cellulose casings

- Bio-Based Panliners Application Data

Details

For the application in pan liners, Arnitel® Eco offers a range of benefits. These include a reduction of 65% in the carbon footprint compared to the material that is traditionally used, significant reduction in food being wasted and lower cleaning costs thanks to a reduction in the use of detergents, energy and labor. Especially for food contact applications, Arnitel® Eco has an important feature: food does not stick to it. This gives a higher yield and quality of the food presented.Benefits

- Arnitel® Eco TPC allows for more sustainable solutions, since it offers 65% CO₂ reduction compared to conventional materails and sincefood does not stick to the panliner made in Arnitel® Eco

- Arnitel® Eco TPC allows for more reliable solutions due to its extremely durability and temperature resistance up to 200°C

- Cooking Bag Application Data

Details

Cooking bags great way to prepare food. The only problem is the tendency of contents like chicken or ham to stick to the bag as the oven gets hotter. The result: wastage and a slightly disappointing eating experience. Not any more, thanks to Arnitel® Eco thermoplastic.Benefits

- Arnitel® TPC allows for reliable solutions due to its extreme elasticity, incredible strength and temperature resistamce up to 200°C

- Arnitel® TPC allows for solutions with soft touch and feel

- Arnitel® TPC allows for sustainable solutions, since the food does not stick to the package thereby reducing food waste

- Snowboard Cover Laminates Application Data

Details

Arnitel® can accept the colorful and complex designs that snowboarders demand via sublimation printingBenefits

- Arnitel® TPC EM740 allows for reliable solutions due to its combination of a Shore D hardness of 74, its superior cold temperature impact resistance and fatigue endurance and due to its good UV resistance

- Arnitel® TPC EM740 allows for cost effective solutions since it can be bonded well to the board substrate

Properties

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Other Properties

- Mechanical Properties (Die Cutting)

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Flexural Modulus | 350 | MPa | ISO 178 |

| Charpy Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eU |

| Izod Notched Impact Strength (at -30°C) | 4.8 | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 210 | °C | ISO 11357-1/-3 |

| Glass Transition Temperature (at 10°C/min) | -2 | °C | ISO 11357-1/-2 |

| Vicat Softening Temperature (50°C/h 50N) | 99 | °C | ISO 306 |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity | >1E13 | Ohm*m | IEC 62631-3-1 |

| Surface Resistivity | >1E15 | Ohm | IEC 62631-3-2 |

| Electric Strength | 20 | kV/mm | IEC 60243-1 |

| Value | Units | Test Method / Conditions | |

| Water Absorption in Water (at 23°C after 24h) | 0.15 | % | ISO 62 |

| Humidity Absorption | 0.01 | % | Sim. to ISO 62 |

| Density | 1230 | kg/m³ | ISO 1183 |

| Biobased Content | 22 | % (Bio C/Total C) | ASTM D6866-12 Method B |

| Value | Units | Test Method / Conditions | |

| Stress at Break (normal) | 49 | MPa | ISO 527-1/-2 |

| Strain at Break (normal) | 640 | % | ISO 527-1/-2 |

| Tear Strength (normal) | 169 | kN/m | ISO 34-1; Method B |

| Tear Strength (parallel) | 190 | kN/m | ISO 34-1; Method B |

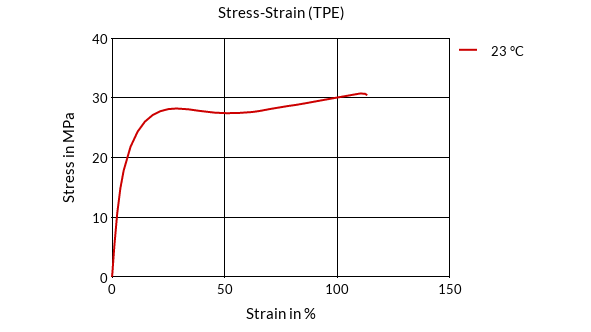

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 340 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 17 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 23 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 26 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 27 | MPa | ISO 527-1/-2 |

| Stress at Break | 27 | MPa | ISO 527-1/-2 |

| Nominal Strain at Break | 105 | % | ISO 527-1/-2 |

| Compression Set Under Constant Strain (at 70°C) | 40 | % | ISO 815 |

| Shore D Hardness (3s) | 65 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 5 | cm³/10min | ISO 1133 |

| Molding Shrinkage (parallel) | 1.5 | % | Sim. to ISO 294-4 |

| Molding Shrinkage (parallel) | 1.5 | % | ISO 294-4 |

| Molding Shrinkage (normal) | 1.75 | % | ISO 294-4 |

| Molding Shrinkage (normal) | 1.75 | % | Sim. to ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

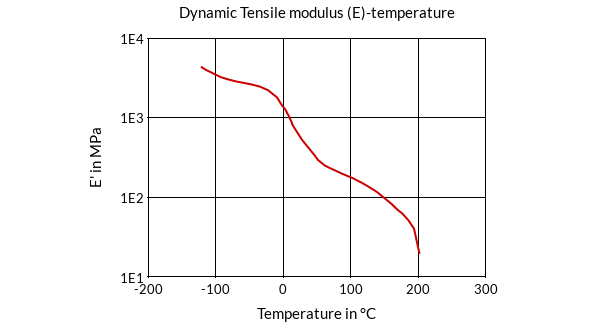

- Dynamic Tensile Modulus (E)-Temperature

- Chemical Resistance

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Stress-Strain (TPE)

Packaging & Availability

- Packaging Type