Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Smartwatch Straps Application Data

Details

Arnitel® provides a good balance of physical and chemical properties: the end product has superior soft touch and feel, is very comfortable to wear in in direct skin contact, and causes no allergic reactions. Arnitel® is resistant to perspiration and to the various oils and other liquids that the strap of the watch is likely to come into contact with during use. Furthermore, the material is easy to process via injection molding, and can be used in hybrid over molded structures with other thermoplastics such as polycarbonate. The intrinsically bright Arnitel® polymer, together with its high UV resistance, enables the production of compounds in a broad range of colors, including ultra-white.

Benefits

- Arnitel® TPC allows for comfortable solutions due to its good soft touch and feel, a nice surface finishing and a tuneable hardness below TPU's and TiPSiv

- Arnitel® TPC allows for reliable solutions due to its good color and UV stability, its excellent mechanical properties and its high performance at low & high temperatures

Properties

- Thermal Properties

- Material Specific Properties

- Other Properties

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 165 | °C | ISO 11357-1/-3 |

| Glass Transition Temperature from DMTA (tan d) | -68 | °C | ASTM D5026/D7028 |

| Relative Temperature Index (Electrical, 1.2 mm) | 50 | °C | UL746B |

| Relative Temperature Index (with impact, 1.2 mm) | 50 | °C | UL746B |

| Relative Temperature Index (without impact, 1.2 mm) | 50 | °C | UL746B |

| Value | Units | Test Method / Conditions | |

| Viscosity Number | 3.32 | cm³/g | ISO 307, 1157, 1628 |

| Value | Units | Test Method / Conditions | |

| Water Absorption in Water (at 23°C after 24h) | 1.8 | % | ISO 62 |

| Humidity Absorption | 0.12 | % | Sim. to ISO 62 |

| Density | 1060 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

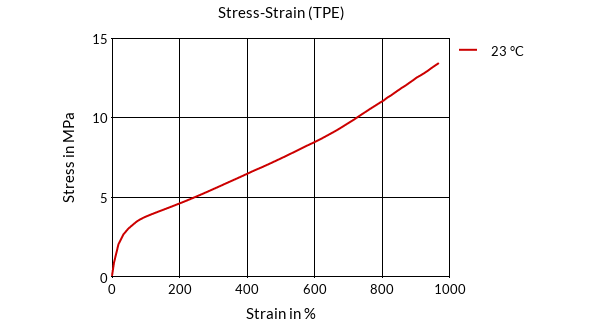

| Tensile Modulus | 16 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 0.8 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 1.4 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 3.1 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 3.8 | MPa | ISO 527-1/-2 |

| Stress at Break | 14.4 | MPa | ISO 527-1/-2 |

| Strain at Break | >300 | % | ISO 527-1/-2 |

| Nominal Strain at Break | 980 | % | ISO 527-1/-2 |

| Shore A Hardness (3s) | 80 | — | ISO 868 |

| Shore A Hardness (15s) | 79 | — | ISO 868 |

| Shore D Hardness (3s) | 19 | — | ISO 868 |

| Shore D Hardness (15s) | 18 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 76 | cm³/10min | ISO 1133 |

| Molding Shrinkage (parallel) | 0.7 | % | Sim. to ISO 294-4 |

| Molding Shrinkage (normal) | 1 | % | Sim. to ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

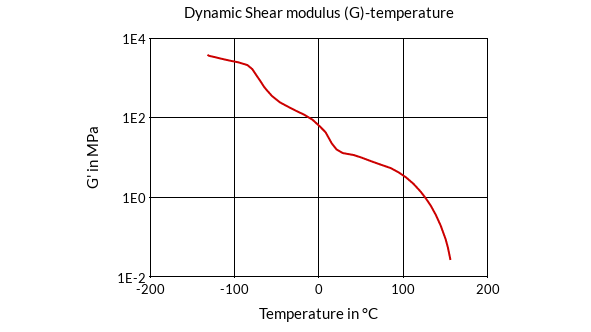

- Dynamic Shear Modulus (G)-Temperature

- Chemical Resistance

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Stress-Strain (TPE)

Packaging & Availability

- Packaging Type