Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Screw Drivers and Plyers Application Data

Benefits

- Arnitel® TPC allows for reliable solutions due to its retention of flexibility even at temperatures down to -40°C or at elevated temperatures up to 100 ˚C

- Arnitel® TPC allows for solutions with nice toch & feel characteristics

- Virtual Reality Application Data

Details

Different Arnitel grades used in VR headware, combining the excellent skin chemical resistance with comfort, durability and manufacture ability.Benefits

- Arnitel® offers high elasticity, low creep and high chemical resistance

- Arnitel offers excellent bonding to substrates like PC without adhesives

- Arnitel has no skin sensitivity issues

- Spider Couplings Application Data

Details

A spider coupling ensures misalignment in metal shaft connections does not affect the lifetime of the couplers. In essence, the spider coupling dampens the initial hit when the shafts start to rotate.Benefits

- Arnitel® offers high load bearing capabilities at high temperature

- Arnitel ® offers excellent low temperature ductility

- Arnitel® has good chemical resistance

- Arnitel® has excellent fatigue properties

- Insecticide Bottle Plug Application Data

Details

The plug of the bottle processed from our Arnitel® products give the benefit to be very chemical resistant and to be comfortable.Benefits

- Chemical resistance to kerosene

- Soft material

- Comfort in PA brush insertion

- Support Springs Application Data

Details

Low creep flexing solution for slats and mattresses, creating ultimate sleep comfort by changing durometer per section of your bed.

Benefits

- Arnitel® has high creep resistance

- Arnitel® offers a wide range of flexible products, creating the ultimate solution

- Arnitel® offers easy processing, creating design flexibility

Properties

- Flame Rating

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Other Properties

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Yield Stress | 14 | MPa | ISO 527-1/-2 |

| Yield Strain | 33 | % | ISO 527-1/-2 |

| Nominal Strain at Break | >50 | % | ISO 527-1/-2 |

| Charpy Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | 25 | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 180/1A |

| Izod Notched Impact Strength (at -20°C) | N | kJ/m² | ISO 180/1A |

| Tensile Notched Impact Strength (at +23°C) | 216 | kJ/m² | ISO 8256/1 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 207 | °C | ISO 11357-1/-3 |

| Glass Transition Temperature (at 10°C/min) | -64 | °C | ISO 11357-1/-2 |

| Temperature of Deflection Under Load (0.45 MPa) | 110 | °C | ISO 75-1/-2 |

| Vicat Softening Temperature (50°C/h 50N) | 90 | °C | ISO 306 |

| Coefficient of Linear Thermal Expansion (parallel) | 2 | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (normal) | 2 | E-4/°C | ISO 11359-1/-2 |

| Burning Behaviour (at 1.5 mm Nominal Thickness) | UL HB | class | IEC 60695-11-10 |

| Glow Wire Flammability Index (at thickness 1 / - mm) | 750 | °C | IEC 60695-2-12 |

| Glow Wire Flammability Index (at thickness 2 / - mm) | 750 | °C | IEC 60695-2-12 |

| Relative Temperature Index (Electrical, 1.5 mm) | 50 | °C | UL746B |

| Relative Temperature Index (with impact, 1.5 mm) | 50 | °C | UL746B |

| Relative Temperature Index (without impact, 1.5 mm) | 50 | °C | UL746B |

| Value | Units | Test Method / Conditions | |

| Relative Permittivity (100Hz) | 4.4 | — | IEC 62631-2-1 |

| Relative Permittivity (1 MHz) | 4 | — | IEC 62631-2-1 |

| Dissipation Factor (1 MHz) | 400 | E-4 | IEC 62631-2-1 |

| Volume Resistivity | 1E11 | Ohm*m | IEC 62631-3-1 |

| Electric Strength | 21 | kV/mm | IEC 60243-1 |

| Comparative Tracking Index | 600 | V | IEC 60112 |

| Value | Units | Test Method / Conditions | |

| Water Absorption | 0.65 | % | Sim. to ISO 62 |

| Humidity Absorption | 0.2 | % | Sim. to ISO 62 |

| Density | 1200 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 170 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 7.4 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 11.1 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 13.8 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 13.7 | MPa | ISO 527-1/-2 |

| Stress at Break | 32 | MPa | ISO 527-1/-2 |

| Strain at Break | >300 | % | ISO 527-1/-2 |

| Nominal Strain at Break | 640 | % | ISO 527-1/-2 |

| Compression Set Under Constant Strain (at 70°C) | 40 | % | ISO 815 |

| Tear Strength | 150 | kN/m | ISO 34-1; Method B |

| Shore D Hardness (3s) | 53 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 36 | cm³/10min | ISO 1133 |

| Molding Shrinkage (parallel) | 1.55 | % | Sim. to ISO 294-4 |

| Molding Shrinkage (normal) | 1.55 | % | Sim. to ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

- OEM Specifications

- OEM Standards

- Quality Standards

Technical Details & Test Data

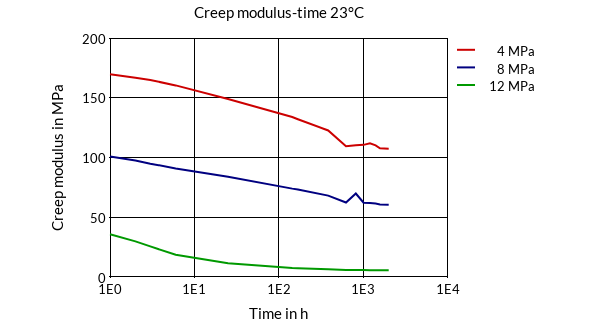

- Creep Modulus-Time 23°C

- Chemical Resistance

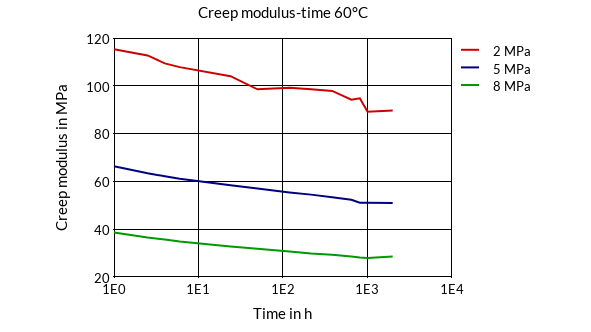

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Creep Modulus-Time 60°C

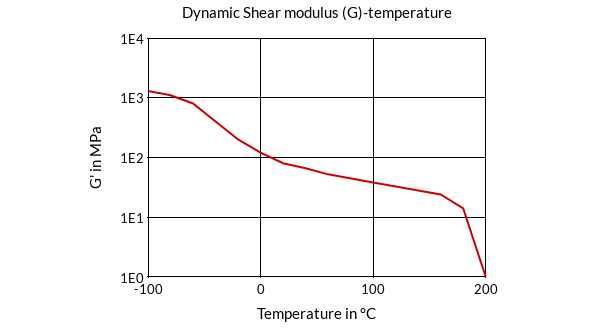

- Dynamic Shear Modulus (G)-Temperature

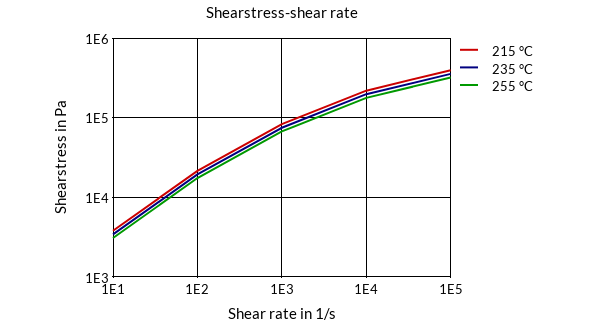

- Shearstress-Shear Rate

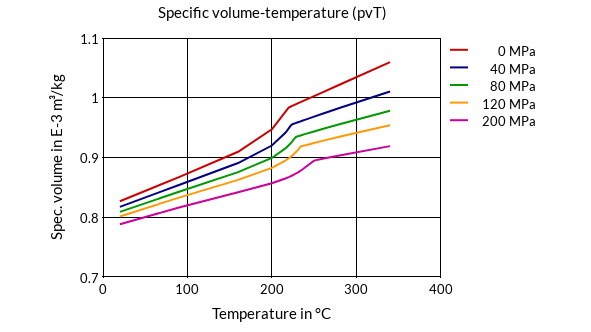

- Specific Volume-Temperature (pvT)

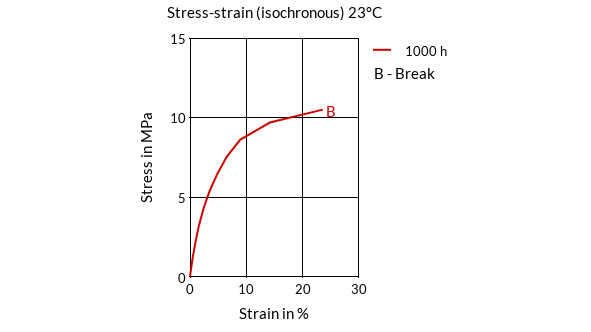

- Stress-Strain (isochronous) 23°C

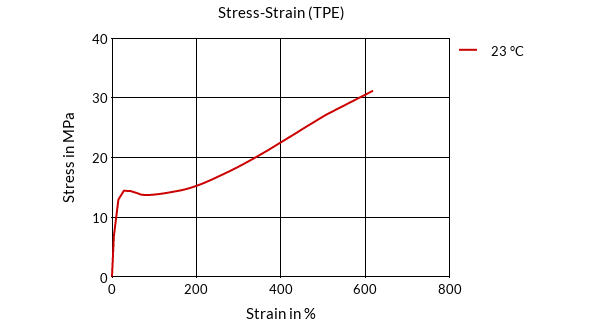

- Stress-Strain (TPE)

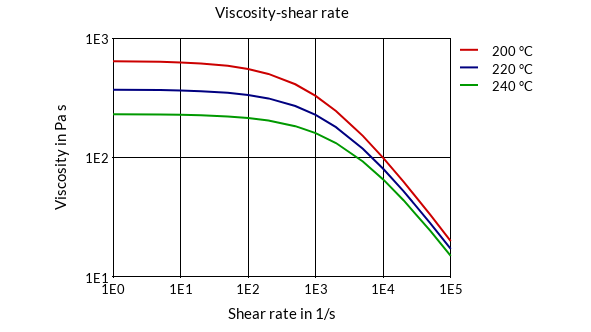

- Viscosity-Shear Rate

Packaging & Availability

- Packaging Type