Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Hot Charged Air Ducts Application Data

Details

Akulon® PA6 is used for temperature up to 150-180˚C.Benefits

- Stanyl® PA46, Stanyl® Diablo PA46, Akulon® Diablo PA and Arnitel® HT TPC allow for light weight solutions as compared to metal or rubber or alternative plastics (Stanyl® is 10% lighter than PPS)

- Stanyl® PA46, Stanyl® Diablo PA46, Akulon® Diablo PA and Arnitel® HT TPC allow for cost effective solutions (Stanyl lowers system cost up to 20% versus metal)

- Stanyl® PA46, Stanyl® Diablo PA46, Akulon® Diablo PA and Arnitel® HT TPC allow for reliable solutions (Stanyl® Diablo is long term resistant up to 230 ˚C, Akulon® Diablo ca be used around 200 ˚C) and Arnitel® HT is ideal as single part solution for flexible hot charge ducts.

- Clean Air Inlet Ducts Application Data

Details

Blow molding grades and injection molding grades are available. For even higher temperatures Diablo grades are available.Benefits

- Arnitel® TPC allows for light weight solutions (50% lighter than rubber)

- Arnitel® TPC allows for reliable solutions due to its perfect combination of high (aging) temperature resistance and good flexibility and chemical resistance

- Akulon® PA6 allows for light weight solutions (50% lighter than metal) and for more rigid duct solutions.

Properties

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Other Properties

- Mechanical Properties (Die Cutting)

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Flexural Modulus | 305 | MPa | ISO 178 |

| Flexural Modulus (at 120°C) | 95 | MPa | ISO 178 |

| Charpy Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | 8.7 | kJ/m² | ISO 179/1eA |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 206 | °C | ISO 11357-1/-3 |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity | 1E13 | Ohm*m | IEC 62631-3-1 |

| Value | Units | Test Method / Conditions | |

| Density | 1270 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Stress at Break (normal) | 45 | MPa | ISO 527-1/-2 |

| Stress at 5% strain (normal) | 12 | MPa | ISO 527-1/-2 |

| Stress at 10% strain (normal) | 17 | MPa | ISO 527-1/-2 |

| Stress at 50% strain (normal) | 20 | MPa | ISO 527-1/-2 |

| Stress at 100% strain (normal) | 20 | MPa | ISO 527-1/-2 |

| Strain at Break (normal) | 630 | % | ISO 527-1/-2 |

| Tear Strength (normal) | 175 | kN/m | ISO 34-1; Method B |

| Tear Strength (parallel) | 203 | kN/m | ISO 34-1; Method B |

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 270 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 13 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 19 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 25 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 25 | MPa | ISO 527-1/-2 |

| Stress at Break | 26 | MPa | ISO 527-1/-2 |

| Nominal Strain at Break | 290 | % | ISO 527-1/-2 |

| Shore D Hardness (3s) | 61 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

| Melt Flow Index (at 230 °C, 10 kg) | 25 | g/10min | ISO 1133 |

Regulatory & Compliance

- Certifications & Compliance

- OEM Specifications

- OEM Standards

Technical Details & Test Data

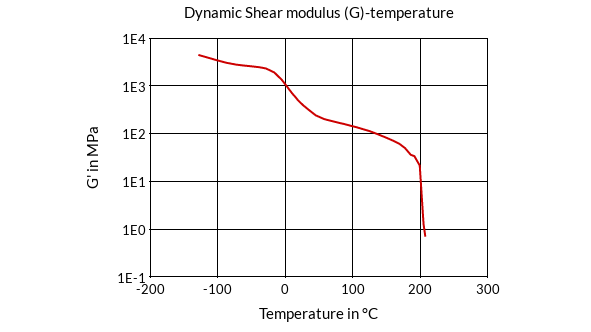

- Dynamic Shear Modulus (G)-Temperature

- Chemical Resistance

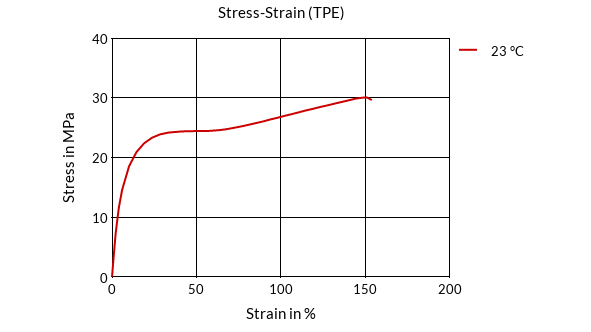

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Stress-Strain (TPE)

Packaging & Availability

- Packaging Type