Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Body Plugs Application Data

Details

Plugholes are essential in the car chassis to enable both the outside and inside of the chassis beams to be coated against corrosion. During assembly, these holes need to be sealed to keep water out, hence body plugs. Because body plugs can be exposed to the curing temperatures of the electrostatic painting line, they need to withstand temperatures of up to 200°C for up to half an hour. Arnitel® has been used for some 25 years for this key application at various grades of strength ranging from 38 Shore D to 60 Shore D with a typical tensile modulus range of 60 MPa – 300 MPa. PL420-H is most commonly used for this application, specialty grades make use of PL381-H and EL591

Benefits

- Arnitel® offers the best combination of peak temperature, flexibility and processability

- Arnitel® has a proven portfolio of grades suitable for different types of bodyplugs

Properties

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Other Properties

- Mechanical Properties (Die Cutting)

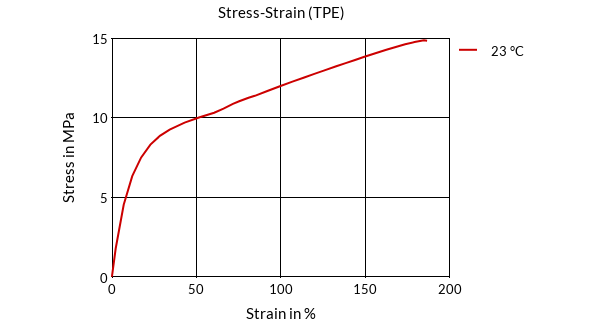

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Flexural Modulus | 80 | MPa | ISO 178 |

| Charpy Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 180/1A |

| Izod Notched Impact Strength (at -20°C) | N | kJ/m² | ISO 180/1A |

| Izod Notched Impact Strength (at -30°C) | N | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 220 | °C | ISO 11357-1/-3 |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity | >1E13 | Ohm*m | IEC 62631-3-1 |

| Value | Units | Test Method / Conditions | |

| Density | 1180 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Stress at Break (normal) | 13 | MPa | ISO 527-1/-2 |

| Strain at Break (normal) | 330 | % | ISO 527-1/-2 |

| Tear Strength (normal) | 105 | kN/m | ISO 34-1; Method B |

| Tear Strength (parallel) | 97 | kN/m | ISO 34-1; Method B |

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 86 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 6 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 9.6 | MPa | ISO 527-1/-2 |

| Stress at Break | 14 | MPa | ISO 527-1/-2 |

| Nominal Strain at Break | 275 | % | ISO 527-1/-2 |

| Shore D Hardness (3s) | 38 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 23 | cm³/10min | ISO 1133 |

| Molding Shrinkage (parallel) | 1.6 | % | Sim. to ISO 294-4 |

| Molding Shrinkage (normal) | 1.75 | % | Sim. to ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

- OEM Specifications

- OEM Standards

Technical Details & Test Data

- Chemical Resistance

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Stress-Strain (TPE)

Packaging & Availability

- Packaging Type