Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- House Wrap Application Data

Details

The roofing membrane uses the EM400+UV MB and EM402-L, whereas the house wrap uses PL381 and PM381.

Benefits

- Arnitel® offers intrinsic breathability at the same level of TPU

- Arnitel® allows for the possibility to run at lower film thickness and at higher extrusion speed versus TPU, which allows for a lower cost system

- Arnitel® has a commercial track record for over 20 years

- Breathable Films For Food Packaging Application Data

Details

Akulon® PA6 used in barrier films for food packaging.Benefits

Arnitel® TPC allows for reliable solutions, since it yields a breathable film that balances the application-specific gas mixture of O2 and CO₂, and the moisture inside the package- Mandrels as Supportive Tool Application Data

Details

Peroxide resistant Arnitel® mandrels for rubber and elastomer hose manufacturingBenefits

- Arnitel® (TPE) offers in extrusion lower torque and better stability measured in tolerances

- Easier to extract the mandrels from the tubes than alternative materials

- Cost reduction compared by increasing the number of re-use cycles (raw material and waste saving)

- Infusion Membrane Bags Application Data

Details

The Arnitel® based films are used as the outside layer of the composite production structure (boats, aeronautics) referred to as vacuum bagging film or infusion membrane.Benefits

- Arnitel® TPC allow for reliable solutions due its excellent balance of properties including chemical resistance, flexibility and resistance to degradation during curing

- Arnitel® TPC allow for cost effective solutions due its ease of processing and

- Industrial Cords and Ropes Application Data

Details

Arnitel® offers the perfect anti-corrosion solution for steel cables used in off-shore industry, like drilling rigs and larger sea vessels. Arnitel® protects the steel from damage due to metal to metal contact and wear, leading to a much longer lifetime.

Benefits

- Arnitel® has a proven track record in off shore cables

- Arnitel® material is suitable for most extrusion techniques

- Arnitel® offers excellent colorability

Properties

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Other Properties

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Charpy Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 180/1A |

| Izod Notched Impact Strength (at -30°C) | N | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 212 | °C | ISO 11357-1/-3 |

| Vicat Softening Temperature (50°C/h 10N) | 127 | °C | ISO 306 |

| Vicat Softening Temperature (50°C/h 50N) | 120 | °C | ISO 306 |

| Coefficient of Linear Thermal Expansion (parallel) | 1.5 | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (normal) | 1.5 | E-4/°C | ISO 11359-1/-2 |

| Value | Units | Test Method / Conditions | |

| Relative Permittivity (100Hz) | 4.7 | — | IEC 62631-2-1 |

| Relative Permittivity (1 MHz) | 4.4 | — | IEC 62631-2-1 |

| Dissipation Factor (100 Hz) | 310 | E-4 | IEC 62631-2-1 |

| Dissipation Factor (1 MHz) | 810 | E-4 | IEC 62631-2-1 |

| Volume Resistivity | 1E12 | Ohm*m | IEC 62631-3-1 |

| Electric Strength | 20 | kV/mm | IEC 60243-1 |

| Comparative Tracking Index | 600 | V | IEC 60112 |

| Value | Units | Test Method / Conditions | |

| Water Absorption | 7 | % | Sim. to ISO 62 |

| Humidity Absorption | 0.4 | % | Sim. to ISO 62 |

| Density | 1160 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 42 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 2.2 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 4 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 8.3 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 10.9 | MPa | ISO 527-1/-2 |

| Stress at Break | 12.5 | MPa | ISO 527-1/-2 |

| Nominal Strain at Break | 155 | % | ISO 527-1/-2 |

| Tear Strength | 52 | kN/m | ISO 34-1; Method B |

| Shore D Hardness (3s) | 32 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 4.7 | cm³/10min | ISO 1133 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Chemical Resistance

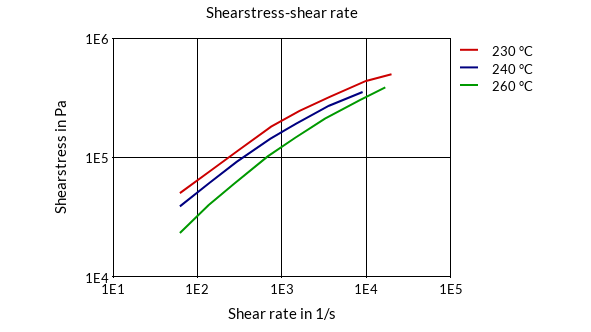

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Shearstress-Shear Rate

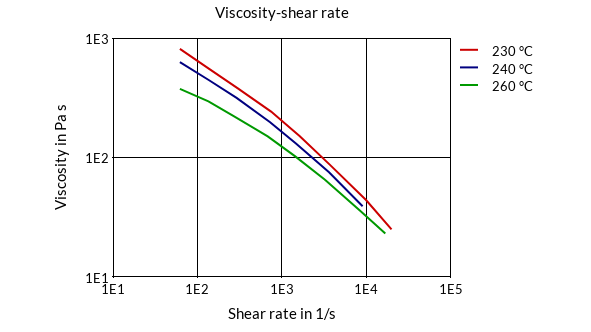

- Viscosity-Shear Rate

Packaging & Availability

- Packaging Type