Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Breathable Films For Food Packaging Application Data

Details

Akulon® PA6 used in barrier films for food packaging.Benefits

Arnitel® TPC allows for reliable solutions, since it yields a breathable film that balances the application-specific gas mixture of O2 and CO₂, and the moisture inside the package- Smokable Sausage Casings Application Data

Details

Arnitel® ECO is bio-based material with up to 50% reduction in carbon footprint.Benefits

- Arnitel® TPC and Akulon® PA6 allow for reliable solutions since they yield excellent smoke penetration leading to great taste and sausage structure and high quality

- Arnitel® TPC and Akulon® PA6 allow for sustainable solutions, since they are free of substances of hazardous concerns and thus more environmentally friendly than cellulose casings

- Roofing Membranes Application Data

Details

Arnitel® TCP is a high-performance thermoplastic copolyester and a reliable roofing solution as it outperforms conventional microporous membranes. The VT series — VT3108, VT3104 and VT3118 — are increasingly used as lighter, smarter, greener alternatives to conventional rubbers as they reduce environmental impact and system costs. They maximize energy efficiency and reduce the carbon footprint in new buildings. Arnitel®’s processing is cost-effective compared to roofing membranes made from thermoplastic polyurethane. For more information on Arnitel® TPC and to request a quote or sample for roofing membranes

Benefits

- Highly breathable

- Flexible and strong

- High temperature resistance

- Eco-friendly

- Extrusion processing.

- Breathable Outdoor Clothing Application Data

Details

With Arnitel® VT, moisture vapor can pass from the inside to the outside of the garment, but the membranes are 100% waterproof under all circumstances, so they keep the wearer comfortable and dry. Unlike competing products, Arnitel® VT does not rely on perforations to make it breathable. Perforated membranes can have their waterproofness compromised when they are washed or come into contact with liquids such as alcohols or fuels. Perforations also reduce the strength of the membrane, making it easier to rip. Perforations can get clogged too, causing the membrane to lose its breathability.Benefits

- Arnitel® TPC allows for very sustainable solutions, since it is PFC free and 100% recyclable

- Arnitel® TPC allows for very comfortable and reliable solutions due to its high breathability and 100% waterproof performance under all circumstances, unlike perforated membranes

Properties

- Mechanical Properties

- Thermal Properties

- Other Properties

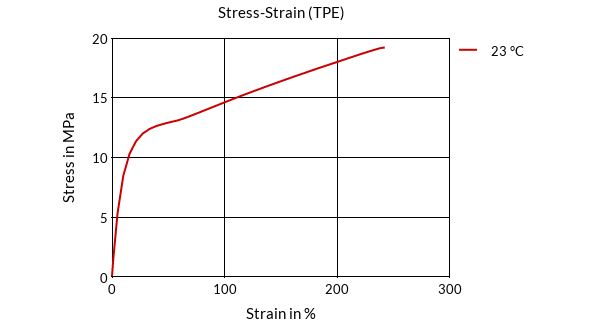

- Mechanical Properties (TPE)

- Rheological Properties

| Value | Units | Test Method / Conditions | |

| Charpy Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | N | kJ/m² | ISO 179/1eA |

| Izod Notched Impact Strength (at +23°C) | N | kJ/m² | ISO 180/1A |

| Izod Notched Impact Strength (at -30°C) | N | kJ/m² | ISO 180/1A |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 185 | °C | ISO 11357-1/-3 |

| Vicat Softening Temperature (50°C/h 10N) | 156 | °C | ISO 306 |

| Vicat Softening Temperature (50°C/h 50N) | 44 | °C | ISO 306 |

| Value | Units | Test Method / Conditions | |

| Water Absorption | 33 | % | Sim. to ISO 62 |

| Density | 1250 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 110 | MPa | ISO 527-1/-2 |

| Stress at 5% strain | 5.1 | MPa | ISO 527-1/-2 |

| Stress at 10% strain | 8.1 | MPa | ISO 527-1/-2 |

| Stress at 50% strain | 12.5 | MPa | ISO 527-1/-2 |

| Stress at 100% strain | 14.1 | MPa | ISO 527-1/-2 |

| Stress at Break | 20 | MPa | ISO 527-1/-2 |

| Nominal Strain at Break | 280 | % | ISO 527-1/-2 |

| Shore D Hardness (3s) | 45 | — | ISO 868 |

| Value | Units | Test Method / Conditions | |

| Melt Volume-Flow Rate (at 230 / * °C, 2.16 / * kg) | 10 | cm³/10min | ISO 1133 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Chemical Resistance

Chemical Type Chemical Name Resistance Other Acetic acid (10% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C limited resistant, tests necessary to verify Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C not resistant Other Calcium chloride (10% by mass) at 23°C limited resistant, tests necessary to verify Other Chloroform at 23°C not resistant Ethers Diethyl ether at 23°C limited resistant, tests necessary to verify Alcohols Ethanol at 23°C limited resistant, tests necessary to verify Other Ethyl Acetate at 23°C limited resistant, tests necessary to verify Other Fuel; Diesel at 85°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C limited resistant, tests necessary to verify Other Nitric acid (10% by mass) at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sulfuric acid (30% by mass) at 23°C resistant Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Hydrocarbons Toluene at 23°C resistant Other Transformer oil at 23°C not resistant Other Trichloroethylene at 23°C not resistant Other Water at 23°C resistant Other Zinc chloride (10% by mass) at 23°C resistant - Stress-Strain (TPE)

Packaging & Availability

- Packaging Type