Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 67762-90-7

Features & Benefits

- Materials Features

- Benefits of SIPERNAT® D-17

- Satisfy your customer with a constant quality of product that does not cake

- Improve powder handling and reduce downtimes

- Reduce addition level of anticaking aid and save costs

- Ensure easy and reliable dosing of your valuable powder

- The Hydrophobic Anticaking Aid.

Due to its hydrophobic nature SIPERNAT® D 17 repels traces of humidity in the powder and prevents caking much more efficient than a regular hydrophilic anticaking agent. With very low addition levels of SIPERNAT® D 17 you can improve even highly hygroscopic powders and keep them flowing after long term storage or transport.

Applications & Uses

- Compatible Polymers & Resins

- Applications

- Well suited for Hydrophobic silica

- Its primary application is as anticaking agent like fire extinguishing powders (anticaking), masking powders for chill casting, manufacture of defoamers / antifoams (fast foam destruction), chemicals (flowability, anticaking), HTV / RTV- 2C / LSR silicone rubber (reinforcing filler).

Typical Applications

- Plasticizers

- Blowing agents

- Antistatic agents

- Anti-fogging agents

Properties

- Physico-Chemical Properties

| Value | Units | Test Method / Conditions | |

| Wettability by Methanol | min. 52 | % | Internal Method |

| Tamped Density (Not Sieved) | 150 | g/l | ISO 787-11 |

| Sulfate Content¹ | max. 1.5 | % | ISO 15350 |

| Sodium Content¹ | max. 1.2 | % | Internal Method |

| SiO₂ Content³ | min. 97 | % | ISO 3262-19 |

| Sieve Residue (in 63 µm Alpine) | max. 1.0 | % | ISO 8130-1 |

| pH Value (in 5% water / methanol 1:1) | 8 | — | ISO 787-9 |

| Particle Size (D50) | 10 | µm | Laser Diffraction, ISO 13320 |

| Loss on Ignition² (at 1000°C, 2 Hours) | max. 6 | % | ISO 3262-1 |

| Loss on Drying (at 105°C, 2 Hours) | max. 6 | % | ISO 787-2 |

| Iron Content¹ | max. 400 | ppm | Internal Method |

| Carbon Content | 1.7 | % | Element Analyser LECO, ISO 3262-19 |

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Efficacy Studies

The two examples below illustrate the superior efficiency of SIPERNAT® D 17 in different applications. The same principle can be applied to numerous other powder applications.

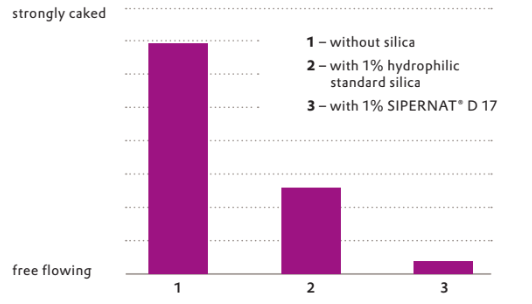

Caking tendency of fire extinguishing powder

In the following test the storage stability of a fire extinguishing powder was tested in a wet/dry cycle. Then the intensity of the caking was evaluated. The results show that the addition of only 1% of the hydrophobic silica grade SIPERNAT® D 17 leads to a significantly lower caking tendency.

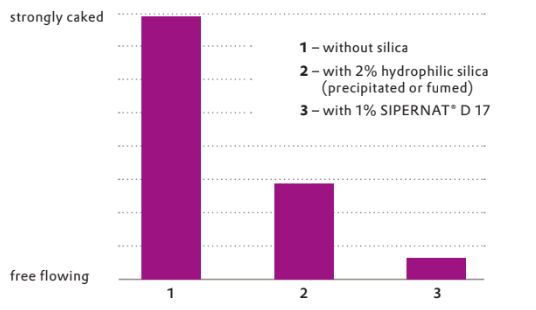

Caking tendency of spray dried hygroscopic polymer

SIPERNAT® D 17 is also ideal to be added as anticaking aid directly into a spray drying process. The diagram on the right side shows that SIPERNAT® D 17 is much more efficient at lower addition levels than hydrophilic precipi-tated or even fumed silica grades.

Packaging & Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Shelf Life

- 24 months

- Storage Conditions

Our silica products are inert and extremely stable chemically. However, due to their high specific surface area, they can absorb moisture and volatile organic compounds from the surrounding atmosphere. Therefore, we recommend storing the products in sealed containers in a dry, cool place, and removed from volatile organic substances. Even if a product is stored under these conditions, after a longer period it can still pick up ambient moisture over time, which could lead to its exceeding the specified moisture content. For this reason, our recommended use-by date is 24 months after date of manufacture. Product more than 24 months old should be tested for moisture content before use in order to make certain that it is still suitable for the intended application.