Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Industrial Additives Functions

Features & Benefits

- Benefits & Advantages

- The special raw material of TEGO® Antifoam 2-89 provide an unique product profile that combines excellent efficiency with maximum compatibility at the same time.

- These properties cannot be achieved with organic or with traditional silicone oil based antifoams.

- Furthermore undesirable effects associated with silicone based antifoams (silicone spotting, fish eyes) can be eliminated in most applications.

- The TEGO® Antifoam product range exceeds customer requirements according to:

- Foam formation during compounding of a final formulation.

- Foam formation during the application of the adhesive.

- Inadequate storage stability

Applications & Uses

- Markets

- Applications

- Adhesive & Sealant Type

- Industrial Additives End Use

- Use Level

- 0.1 wt.% (Initial Dosage), 0.05 - 0.2 wt.%

- Applications

- TEGO® Antifoam 2-89 provides reliable foam control and excellent long-term efficiency especially in pressure sensitive adhesives.

- It may also be used in aqueous media, as well as in the processing and application of polymer dispersions, emulsions and a multitude of other industrial applications (e.g. industrial and household cleaners) where the use of traditional silicone oil based antifoams is restricted for certain reasons.

- Dosage

- In most applications it is beneficial to apply TEGO® Antifoam 2-89 pre-diluted in water (1 : 1 to 1 : 10).

- Depending on the application in question the required dosage may vary over a wide range (0.05 - 0.2 %).

- Suitable screening tests are therefore recommended (initial dosage: 0.1 %).

- Handling

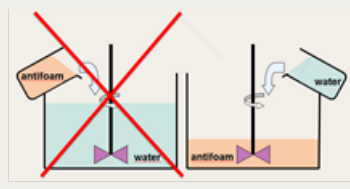

Dilution of TEGO® Antifoam 2-89 may be prepared by adding the desired amount of water to TEGO® Antifoam 2-89 while stirring gently at low shear rates.

The pre-dilution will shorten the storage stability. 1 : 1 dilutions prepared as described above are stable for several days. 1 : 10 dilutions should be processed within several hours. The product has to be stirred before use.

Properties

- Appearance

- White emulsion

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Active Content | 20 | % | — |

| Density (at 25°C) | approx. 1.0 | g/cm³ | — |

| Viscosity (Dynamic, 25°C) | approx. 400 | mPa.s | DIN 53019 |

| pH Value (25°C, Delivered Form) | 8.5 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Framework of LCA

Goal:

- Calculation of the environmental performance of products manufactured and sold by Business Line Interface & Performance.

System Boundary:

- Cradle-to-Gate

Functional Unit (FU):

- 1 kg TEGO® Antifoam 2-89

Methodology:

- All our Life Cycle Assessments are following the principles of ISO 14040/44 and ISO 14067 standards.

- The established method of the Dutch Environmental Science Research Center Leiden (CML) with characterization factors from November 2013 was used.

- Data Sources: The LCA was created in 2020 by an internal Life Cycle Management team.

- The LCA is based on primary data from the year 2014 by Evonik for the production process, while secondary data from databases (such as GaBi and ecoinvent), suppliers or literature is utilized for external processes and raw materials.

- The software GaBi 10 was used for the LCA modeling.

- The data for energy consumption were updated with values from 2021.

Cut-off rules for the inventory:

- In general, 1% for single inputs and below 5% for the sum.

- No environmentally relevant flows were neglected.

- Some utilities of production processes have been modeled analog to known processes.

- Transports have been considered but distances have mainly been estimated.

- The result uncertainty in all categories is about +/- 20 % as these results base on several assumptions.

Result (Cradle-to-Gate):

Evaluation variables Value Unit per FU Blue water consumption 11.7 kg Global Warming Potential incl. LUC 1.4 kg CO2 eq. Primary Energy Demand 30.7 MJ

Packaging & Availability

- Packaging Type

- Packaging

- 210 kg plastic drums (840 kg each pallet)

- 1000 kg containers

Storage & Handling

- Shelf Life

- max. 6 months

- Storage Conditions

It is stable in closed containers for a minimum of 6 months. It must be stored in frostfree conditions.