Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Benefits

- Ability to machine tool surface without distortion permitting the manufacture of tools with complex shapes and tight tolerances

- Reparability and potential for modification of tool dimensions following engineering changes

- Elevated Tg and service temperature (average Tg onset DMA 220°C) allowing use of components cure from 120°C to 180°C

- Formulated to withstand more than 100 part cure cycles at 120°C

- Rapid material deposition as HexTool® is much thicker than standard composite tooling prepregs and do not require accurate lay up schedule thanks to our quasi isotropic property

- 21 days out life compare to just few days for tooling prepregs

- Coefficient of thermal expansion to match carbon/epoxy

- Vacuum integrity following machining

Applications & Uses

- Markets

- Composites Processing Methods

Properties

- Physical Form

- Mechanical Properties

- Cured Properties

- Uncured Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength Room Temp. (Dry) | 175 | MPa | ASTMD3039 |

| Tensile Strength at 120°C (Dry) | 170 | MPa | ASTMD3039 |

| Tensile Modulus Room Temp. (Dry) | 43 | GPa | ASTMD3039 |

| Tensile Modulus at 120°C (Dry) | 40 | GPa | ASTMD3039 |

| Compression Strength Room Temp. (Dry) | 250 | MPa | ASTMD6484 |

| Compression Strength at 120°C (Dry) | 250 | MPa | ASTMD6484 |

| Compression Modulus Room Temp. (Dry) | 30 | GPa | ASTMD6484 |

| Compression Modulus at 120°C (Dry) | 30 | GPa | ASTMD6484 |

| Short Beam Shear Strength Room Temp. (Dry) | 45 | MPa | EN2563 |

| Short Beam Shear Strength at 120°C (Dry) | 35 | MPa | EN2563 |

| Value | Units | Test Method / Conditions | |

| Cured Ply Thickness | 1.28 | mm | — |

| Tg Postcured | 220 | °C | — |

| Maximum Use Temperature | 185 | °C | — |

| Coefficient of Linear Thermal Expansion | 5x10-6 | °C | ASTM E 228 |

| Minimum Initial Cure Temperature | 125 | °C | — |

| Value | Units | Test Method / Conditions | |

| Nominal Resin Content | 38 | % | — |

| Nominal HexTool® Ply Areal Weight | 2000 | g/m2 | — |

| Nominal Resin Content | 55 | % | — |

| Nominal Bundle Size (Prepreg Strip Size) | 8.0 x 50 | mm | — |

| Specific gravity | 1.57 | — | — |

| Autoclave Work life at 21°C | 20 days | — | — |

| Storage Life at -18°C | 12 months | — | — |

Technical Details & Test Data

- Cured Prepreg Mechanical Properties

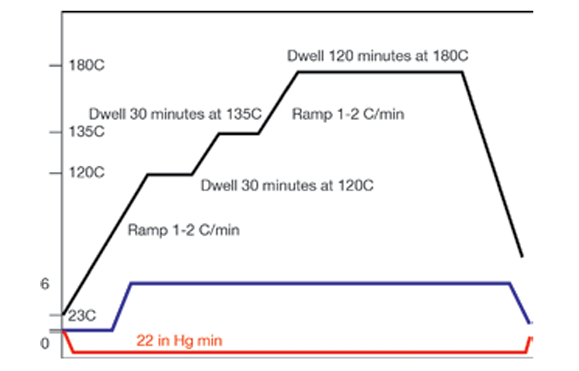

Specific cure cycles [temperature, pressure (amount and application of)] depend on autoclave type and dimensions, the extent and type of tooling used and the size and complexity of the lay-up. Please contact your local Hexcel Technical Support for consultation prior to cycle definition. The following cycles are typical for HexTool® M81.

Low Temp Cure Cycle and Post Cure 125°C Autoclave Cure Cycle

- Apply full vacuum (>0.85bar)

- Heat up to 125°C using a ramp between 0.5° and 1°C/min

- Apply 7bar gage pressure when temperature reaches 50°C

- Hold at 125°C for 360 minutes

- Cool down using a 0.5°C/min ramp to 60°C

- At 60°C release pressure and vacuum

Free Standing Post Cure Cycle

- Heat up to 140°C using a ramp between 0.5° and 2°C/min

- Heat up to 205°C using a ramp between 0.25° and 1°C/min

- Hold at 205°C for 2 hours

- Cool down using a 0.5°C/min ramp to 150°C

- Cool down using a 1°C/min ramp to 60°C

Higher Temp Cure Cycle

- Introduce full vacuum of 22 inches Hg minimum. (Vacuum is to maintained throughout cure cycle)

- Begin heat up to 120°C at 1°-2° C/min.

- When leading Tc reaches 50° +/-2.5°C apply 6 bars pressure

- Continue heat up to 120°C

- When lagging Tc reaches 120° +/-2.5°C, begin 30 minute soak.

- Continue heat up to 135°C

- When lagging Tc reaches 135°+/-2.5°C, begin 30 minute soak.

- Continue heat up to 180°C at 1°-2°C/min.

- When Lagging Tc reaches 180° +/-2.5°C, begin 120 minute hold.

- Cool part to 50°C at 0.5°-4°C /min. before releasing pressure.

Storage & Handling

- Product Handling and Storage

- Shelf Life¹: 12 months at -18°C (from date of manufacture).

- Out Life²: 21 days at Room Temperature

- Tack Life³ : 10 days at Room Temperature

- ¹ Shelf Life: the maximum storage life for HexPly® prepreg, upon receipt by the customer, when stored continuously, in asealed moistureproof bag, at -18°C. To accurately establish the exact expiry date, consult the box label.

- ² Out Life: the maximum accumulated time allowed at room temperature between removal from the freezer and cure.

- ³ Tack Life: the time, at room temperature, during which prepreg retains enough tack for easy component lay-up.

Store the product in its original (or equivalent) sealed packaging at -18°C. Prevent condensation on the product by warming to room temperature before opening vapor barrier bag (reseal for subsequent storage).