Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Composite Materials Functions

- CAS No.

- 21645-51-2

- EC No.

- 244-492-7

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

Properties

- Flame Rating

- Chemical Properties

- Typical Properties

- Particle Size Distribution

| Value | Units | Test Method / Conditions | |

| Al(OH)₃ | 99.6 | % | — |

| Fe₂O₃ | 0.007 | % | — |

| Loss on Ignition at 1000°C | 34.6 | % | - |

| Na₂O (Soluble) | 0.025 | % | — |

| Na₂O (Total) | 0.2 | % | — |

| SiO₂ | 0.005 | % | — |

| Value | Units | Test Method / Conditions | |

| Bulk Density (Loose) | 0.85 | g/cm³ | — |

| Bulk Density (Packed) | 1.35 | g/cm³ | — |

| Free Moisture at 105°C | 0.2 | % | - |

| Specific Gravity | 2.42 | - | - |

| Surface Area | 1.2 | m²/gm | - |

| TAPPI Brightness | 87.0 | - | - |

| Value | Units | Test Method / Conditions | |

| Median Particle Diameter | 10.0 | μm | - |

| Screen Analysis < 10 micron | 43.0 | % | - |

| Screen Analysis through 325 mesh | 80.0 | % | - |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Performance

For SMC, BMC, Hand Lay-Up and Polyurethane Applications:

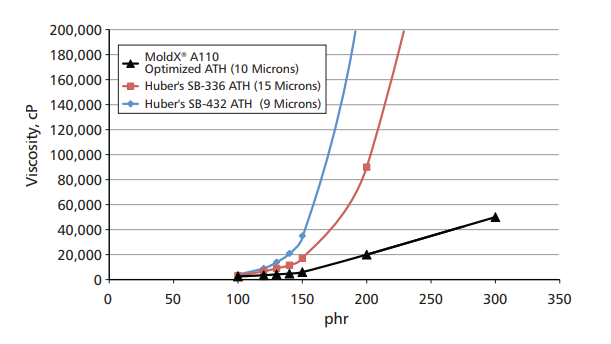

MoldX A110 is an optimized ATH fire retardant capable of very high loading levels, from 250 phr to greater than 350 phr. It is the choice for halogen-free product formulations requiring significant smoke suppression. The low-viscosity performance means MoldX A110 can be processed on SMC machines and BMC mixers at loading levels not thought possible. The outstanding flow characteristics of A110 make it especially well-suited for molding large or intricate parts.

MoldX® A110 Comparative Viscosity in Unsaturated Polyester at 25°C