Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

- Nomenclature

Triglycerides, Polyglycols and emulsifers

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Features and Benefits

Lopon E 81 offers the following advantages:

- VOC-free (< 1000 ppm)

- Very low settling of LOPON® E 81

- Good processing properties of paints and plasters

- Good compatibility with different types of binders

- Good long-term effect

- No negative influence on storage stability of end product

- Conform to Ecolabel, BfR XIV and FDA

- Features

- LOPON® E 81 contains very low VOC making it a suitable replacement for mineral oil and silicone based defoamers. It is also offers ease of application due to its mineral oil and silicone-free chemistry.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Coating Type

- Use Level

- 0.1 - 0.5 %

- Recommended Loading Levels

0.1 – 0.5% related to formula.Added in two steps, Further recommendation (guide recipe) CALGON® N, LOPON® 890

- Applications

- Interior and exterior emulsion paints and plasters, silicone resin paints, emulsion silicate paints and plasters, and adhesives.

Properties

- Physical Form

- Appearance

- Light Yellow, Opaque Viscous Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity | 2300 - 6000 | mPas | — |

| Density (20°C) | 900 – 1100 | g/L | — |

| Renewable Raw Materials | 47 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

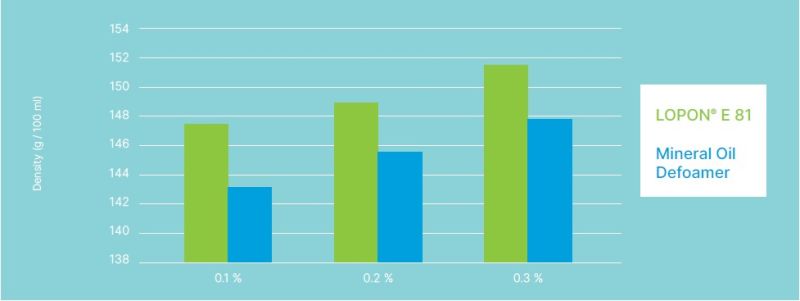

- Study of Defoamer Effect

- Our LOPON® defoamers show a high level of effectiveness when used at low dosage levels.

- For a comparable defoamer effect, a lower dosage of LOPON® E 81 is usually necessary when compared to a traditional mineral oil defoamer.

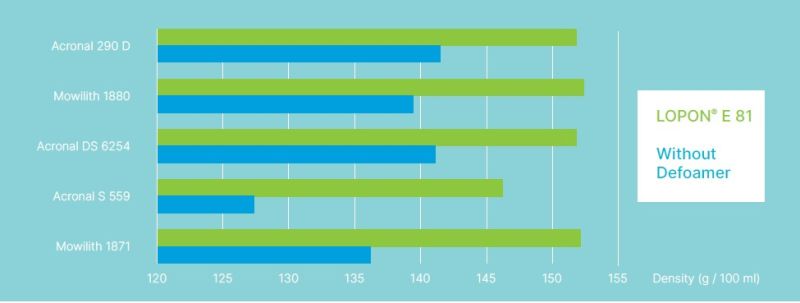

- LOPON® E 81 is quite versatile due to its wide range of effects.

- In addition to our liquid defoamers we also offer a powdery defoamer for use in powder systems.

Exterior paint: With a dosage of only 0.1 % LOPON® E 81, a comparable effect is achieved as with 0.3 % of a conventional mineral oil defoamer.

Exterior paint: With a dosage of only 0.1 % LOPON® E 81, a comparable effect is achieved as with 0.3 % of a conventional mineral oil defoamer.

Effectivity of LOPON® E 81 in different binders: density in g / 100 ml of emulsion paint.

Effectivity of LOPON® E 81 in different binders: density in g / 100 ml of emulsion paint.

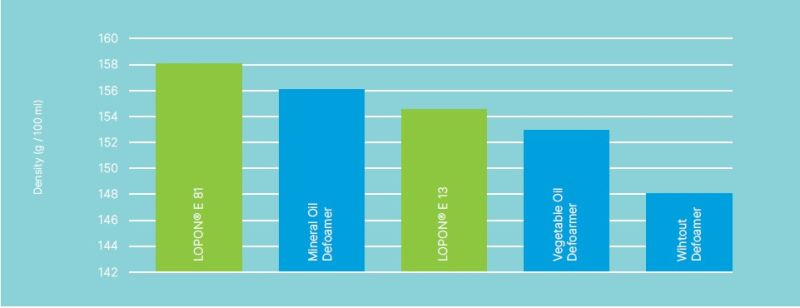

- Sustainable and Eco-Friendly

- While in earlier days mainly mineral oil-based defoamers were used, today increasing emphasis is placed on sustainability. Many of our LOPON® defoamers are based on renewable raw materials which are biodegradable.

- LOPON® E 81 has a percentage of renewable raw materials of 47 %.

- Even more environmentally friendly is our defoamer LOPON® E 13. LOPON® E 13 has a content of 93 % of regrowing materials.

- Compared to our defoamer LOPON® E 81, the effectiveness is slightly reduced but still comparable or even better than biodegradable defoamers from competitors.

- All our LOPON® and TARGON® defoamers have been developed for water-based applications and are suitable for Ecolabel compliant formulations.

Effectivity of LOPON® E 13 compared to different defoamers in a semi-gloss paint with a dosage of 0.3 %

Effectivity of LOPON® E 13 compared to different defoamers in a semi-gloss paint with a dosage of 0.3 %

Storage & Handling

- Shelf Life

- 2 years

- Storage Information

Store at room temperature, protect from frost. Carefully close opened packing after usage