Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Ingredient Origin

- Food Ingredients Functions

- Ingredients

- Corn Starch

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Food Ingredients Features

- The technical application of the corn starch is important for

- the paper industry when manufacturing the coated paper, cardboard, paper tare.

- the building when field painting and trimming.

- the flotation way of ore concentration, the oil-well drilling.

- the textile industry for the smoothing, dressing of fabrics, as a stiffener of printing inks.

- the pharmaceutical industry when manufacturing medicines.

- the tanning, printing, tobacco and other industries.

- the textile industry for the smoothing, dressing of fabrics, as a stiffener of printing inks.

- The Functional Properties

- Adds crumble properties

- Moisture control

- Hygroscopic properties

- Aerating agent properties

- Viscosity control

- Jelly forming properties

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Application

The native starch as a natural polymer is one of the main organic source of raw materials for the food, chemical and other fields of industry. The native starch can be used separately and in mixture with a modified edible starch for getting a thick and dense structure in sauces, deserts and dry mixes. It has a fast solidifying structure and therefore can beused in bakery industry for the control of dough density and giving crumble properties to dry sponges and crackers. The starch helps to control the crust in products which are baked.It increases the friability of dough and bread crumbs and helps tocontrol the viscosity of dough. This starch can be as well used for the forming as a form filler when drying fruit gelatinous, jelly sweets and can be used for the chocolate substitution. It also provides the ability to decrease the chocolate content in solid chocolate formula for the regions with hot climate. In the result of boiling the starch paste can beused as a binding agent while moist granulation in thick masses whichare used in paints. The corn starch might be applied as a absorbent of moisture for the talcum powder and other pharmaceutical powders. One can use it in cheese production as a substance that prevents the conglutination of cheese flakes and as a substance that prevents the conglomeration of the crystalline sugar. The native corn starch serves as a source of carbohydrates during the fermentation in conditions of preheating and hydrolysis before its application.

- In food industry the corn starch is used for

- the preparation of kissels, puddings, ketchups, it is added to the dough when preparing sponges, cakes and other products

- the production of dragée, cakes, cookies, waffles, cups for ice-cream

- the formation of cream, liqueur and chocolate kinds of sweets

- the production of yogurts, ice-cream, some kinds of sausages

Properties

- Odor

- Characteristic without extraneous odor

- Typical Properties

- Microbiological Values

| Value | Units | Test Method / Conditions | |

| After additional grinding (fine-dispersed) | 600 | - | - |

| Bulk Density (loose. After drying) | 400 | g/l | - |

| Energy value of 100g of product | 344 | kkal | - |

| Including ash soluble (10 solution of hydrochloric acid) | max. 40 | % | - |

| Mold | max. 100 | cfu/g | - |

| pH Value | 4-6 | - | - |

| Viscosity | 86 | - | - |

| Amylose | 25-35 | % | - |

| Amylopectin | 65-75 | % | - |

| Total Ash (on dry substance) | max. 0.11 | % | - |

| Protein Content (on dry substance) | max. 0.40 | % | - |

| Sulfur Dioxide | max. 50.0 | ppm | - |

| Moisture Content | max. 13.0 | % | - |

| Acidity | max. 16.0 | cc | - |

| Value | Units | Test Method / Conditions | |

| cfu per g | max. 1x10^3 | - | - |

| Yeast | max. 100 | cfu/g | - |

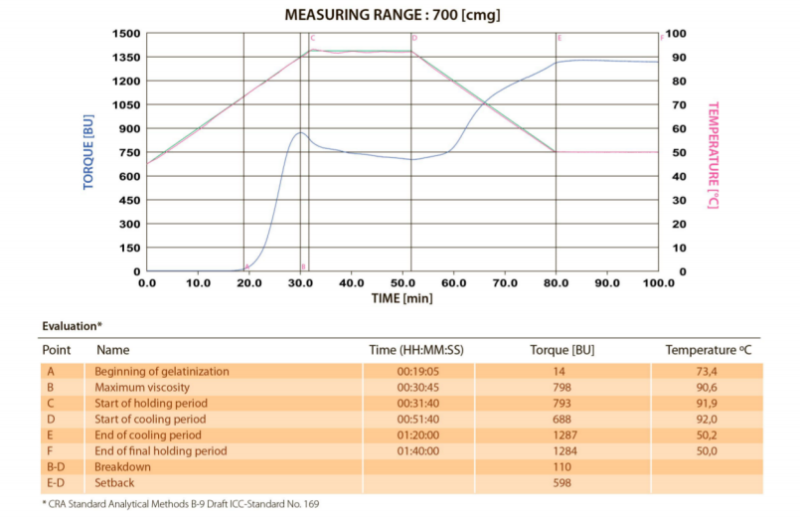

Technical Details & Test Data

- Graph

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage & Packaging

The corn starch is packed in multilayer paper bags with the capacity of 25-30 kg, which are palletized forming big bags with the total capacity 850-1000 kg. The dry corn starch must be stored in well ventilated, clean ware-houses without an extra odor. It must be kept at the temperature not higher than 40°C and relative humidity not higher than 75%.The warranty period of fitness for the dry corn starch, when keeping at normative conditions is two years from the date of production.