Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

- Two options – Life Science Grade and Life Science Grade + Food Grade. Exhibits high stiffness and mechanical strength.

- Components are also sterilizable by means of steam (autoclave), dry heat, EtO, plasma, and gamma- & x-ray irradiation.

- Pre-assessed for biocompatibility on both resin and shape for up to 24 hours contact with body tissue according to USP VI and ISO 10993, as well as wetted contact in bioprocessing.

- Standard food approvals include FDA 21 CFR § 177.2415, while the FG type also includes Regulation (EU) No. 10/2011 food contact approval (which is based on food-related extractable & leaching tests).

- Excellent sterilization resistance via steam, dry heat, Ethylene Oxide, plasma, gamma and x-ray

- Unfilled PEEK base for high mechanical strength and chemical resistance

- Exceptional heat resistance

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Applications

- Those in which the duration of contact with human body tissue is limited up to 24 hours*, as well as wetted contact in bioprocessing.

- This material is an excellent candidate for applications in the medical and bioprocessing fields, such as endoscopes/laparoscopes, manifolds, valves, connectors, lids, and adapters.

Properties

- Flame Rating

- Odor

- Odorless

- Insoluble in

- Water

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Electrical Properties

- Note

Handling (Machining) :

- During machining of the semi-finished products, evacuate swarf to prevent slipping or tripping hazard and observe the maximum allowable concentration of dust and

- formaldehyde levels on the workplace which apply in your country.

- Wear safety goggles during machining.

Storage:

- The products shall be stored indoors in a normal environment (air at 10 - 30°C / 30 - 70% RH) and kept away from any source of degradation such as sunlight, UV-lamps, chemicals (direct or indirect contact), ionizing radiation, flames, etc.

- Dimensional changes (camber, warpage, shrinkage …) of the products as well as slight color shifts of the external surfaces can occur with time.

- The latter does generally not pose a problem in case of semi-finished products since the surface-layer is mostly removed anyway upon machining them into finished parts.

Safety measures:

- Standard industrial safety recommendations shall be observed.

- Temperatures above the melting temperature shall be avoided.

| Value | Units | Test Method / Conditions | |

| Tensile Strength ⁶ | 115.0 | MPa | ISO 527-1/-2 ⁷ |

| Tensile Strain (elongation, at yield) ⁶ | 5.0 | % | ISO 527-1/-2 ⁷ |

| Tensile Strain (elongation, at break) ⁶ | 17.0 | % | ISO 527-1/-2 ⁷ |

| Tensile Modulus of Elasticity ⁶ | 4300.0 | MPa | ISO 527-1/-2 ⁹ |

| Shear Strength ⁶ | 55.0 | psi | ASTM D732 |

| Compressive Stress (at 1% nominal strain) ⁶ | 38.0 | MPa | ISO 604 ¹⁰ |

| Compressive Stress (at 2% nominal strain) ⁶ | 75.0 | MPa | ISO 604 ¹⁰ |

| Compressive Stress (at 5% nominal strain) ⁶ | 140.0 | MPa | ISO 604 ¹⁰ |

| Compressive Strength ⁶ | 20000.0 | psi | ASTM D695 ¹¹ |

| Charpy Impact Strength - Unnotched ⁶ | no break | kJ/m² | ISO 179-1/1eU |

| Charpy Impact Strength - Notched ⁶ | 3.5 | kJ/m² | ISO 179-1/1eA |

| Flexural Strength ⁶ | 170.0 | MPa | ISO 178 ¹² |

| Flexural Modulus of Elasticity ⁶ | 600.0 | ksi | ASTM D790 |

| Rockwell M Hardness ⁶ ¹⁴ | 105.0 | — | ISO 2039-2 |

| Rockwell R Hardness ⁶ ¹⁴ | 126.0 | — | ASTM 2240 |

| Value | Units | Test Method / Conditions | |

| Thermal Decomposition | min. 400 | °C | — |

| Self Ignition Temperature | 595.0 | °C | ASTM D 1929 |

| Density | 1.31 | g/cm³ | ISO 1183-1 |

| Specific Gravity | 1.31 | — | ASTM D792 |

| Water Absorption (after 24h immersion in water of 23 °C) | 0.1 | % | ASTM D570 ¹⁷ |

| Water Absorption (at saturation in water of 23 °C) | 0.45 | % | ASTM D570 ¹⁷ |

| Wear Rate | 28.0 | μm/km | ISO 7148-2 ¹⁸ |

| Dynamic Coefficient of Friction (-) | 0.3 - 0.5 | — | ISO 7148-2 ¹⁸ |

| Limiting PV (at 100 FPM) | 8500.0 | ft.lbs/in².min | QTM 55007 ²¹ |

| Limiting PV (at 0.1 / 1 m/s cylindrical sleeve bearings) | 0.33 / 0.21 | MPa.m/s | — |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (DSC, at 10°C) ¹ | 340.0 | °C | ISO 11357-1/-3 |

| Thermal Conductivity (at 23°C) ¹ | 0.25 | W/(K.m) | — |

| Coefficient of Linear Thermal Expansion (at -40 to 150 °C) ¹ | 26.0 | μin./in./°F | ASTM E-831 (TMA) |

| Coefficient of Linear Thermal Expansion (at 23 to 60°C) ¹ | 50.0 | μm/(m.K) | — |

| Coefficient of Linear Thermal Expansion (at 23 to 100°C) ¹ | 55.0 | μm/(m.K) | — |

| Coefficient of Linear Thermal Expansion (above 150°C) ¹ | 130.0 | μm/(m.K) | — |

| Heat Deflection Temperature (method A, 1.8 MPa) ¹ | 160.0 | °C | ISO 75-1/-2 |

| Continuous Allowable Service Temperature in Air (for 20 hrs) ¹ ³ | 250.0 | °C | — |

| Service Temperature ¹ ⁴ | -50.0 | °C | — |

| Flammability UL 94 (3 mm) ¹ ⁵ | V - 0 | — | — |

| Flammability Oxygen Index ¹ | 35.0 | % | ISO 4589-1/-2 |

| Value | Units | Test Method / Conditions | |

| Electric Strength | 24.0 | kV/mm | IEC 60243-1 ¹⁵ |

| Volume Resistivity | 1 x 10¹⁴ | Ohm.cm | IEC 62631-3-1 |

| Surface Resistivity | 1 x 10¹³ | Ohm/sq. | ANSI/ESD STM 11.11 |

| Dielectric Constant (at 1 MHz) | 3.2 | — | IEC 62631-2-1 |

| Dissipation Factor (at 1MHz) | 0.001 | — | IEC 62631-2-1 |

Regulatory & Compliance

Technical Details & Test Data

- Material Selection

Sterilization Resistance

Compatibility with some commonly used sterilization methods Ethylene

Oxide gasWet heat (steam)

121°C / 134°CDry heat

160°CPlasma Gamma

irradiationX-ray

irradiationKetron® LSG PEEK Very Good Very Good Very Good Very Good Very Good Very Good Chemical Resistance

Weak (dilute) acids Strong acids Oxidising chemicals Weak (dilute) alkalis Strong alkalis Hot water (80°C) Steam Esters

(e.g. ethyl acetate)Ketones

(e.g. acetone)Aromatic hydrocarbons

(e.g. benzene, toluene)Aliphatic hydrocarbons

(e.g. hexane, octane)Ketron® LSG PEEK Resistant - In general acceptable Service Life Partially Resistant - Limited Service Life Partially Resistant - Limited Service Life Resistant - In general acceptable Service Life Resistant - In general acceptable Service Life Resistant - In general acceptable Service Life Resistant - In general acceptable Service Life Resistant - In general acceptable Service Life Resistant - In general acceptable Service Life Resistant - In general acceptable Service Life Resistant - In general acceptable Service Life X-ray Transparency

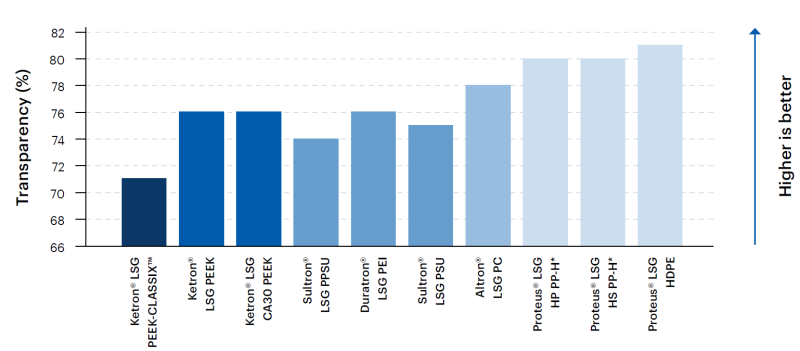

Transparency of the life science grades to high energy radiation (Measured at 23°C on 12 mm thick test plates, applying radiation with an energy level of 59keV)

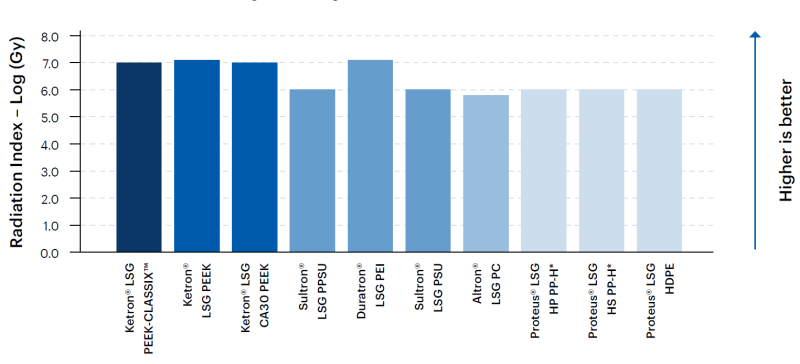

Radiation Resistance

Resistance of the life science grades to gamma radiation

- Index 6 = 106Gy / 1MGy = 106Gy / 1 Gy = 100rad /

- 100rad = 1J/kg / 1J/kg = 6.24.1012MeV/kg

- X-rays energy ranging from 100eV to 100keV. Gamma radiation have energy greater than 100keV.

- The Radiation Index (RI) is defined as the logarith, base 10, of the absorbed dose in Mega grays at which the flexural stress at break or flexural strain at break of the tested material is reduced to 50% of its original value, under specified conditions of irradiation (the most radiation-sensitive of these two properties is chosen as the reference critical property).

Storage & Handling

- Storage and Handling Information

Handling (Machining) :

- During machining of the semi-finished products, evacuate swarf to prevent slipping or tripping hazard and observe the maximum allowable concentration of dust and

- formaldehyde levels on the workplace which apply in your country.

- Wear safety goggles during machining.

Storage:

- The products shall be stored indoors in a normal environment (air at 10 - 30°C / 30 - 70% RH) and kept away from any source of degradation such as sunlight, UV-lamps, chemicals (direct or indirect contact), ionising radiation, flames, etc.

- Dimensional changes (camber, warpage, shrinkage …) of the products as well as slight colour shifts of the external surfaces can occur with time.

- The latter does generally not pose a problem in case of semi-finished products since the surface-layer is mostly removed anyway upon machining them into finished parts.

Safety measures:

- Standard industrial safety recommendations shall be observed.

- Temperatures above the melting temperature shall be avoided.