Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Benefits

- High impact resistance

- High wear resistance

- Low coefficient of friction

- High chemical resistance

- Perfect wheatherability

- No need for lubrication

- Wide operating temperature interval

- educes vibrations and works silently

- Perfect electrical insulation

- Lightweight and economical due to low density

- Easily machined

- Odorless and tasteless

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Applications

- Packaging machines

- Directing guides and rollers in elevators

- Wear plates

- Bunker linings

- Bushes

- Ice skating arenas

- Gaskets

- Impact rods, plates

- Deflectors Gears

- Filter press plates

- Air filters

- Dock fenders

- Mixers Sheaves

- Bucket lining

- Chemistry equipment

- Conveyors

- Pulleys

- Kitchen table plates

- Pumps and pump components

- Water purification system components

- Bottling machines

- Wheels

- Bearings

- Pressing support plates

- Gear wheels

- Food production equipment

- Hydrofoil boxes

- Truck linings

- Ski bases

- Cutting press plates

- Canned food filling lines

- Protector in funfairs

- Material transfer equipment

- Orthopedic components

- Silo lining

- Underwater bearings

- Agriculture machines

- Valve rings

- Directing rods

- Chain gears

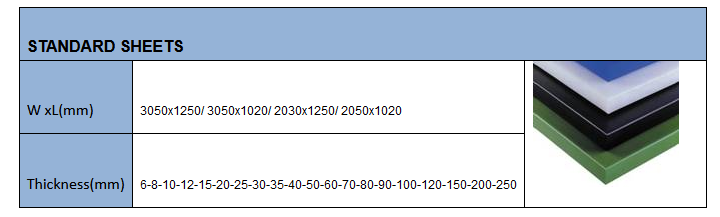

- Standard Sheets

Properties

- Physical Form

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength at Break | 250 | Kg/cm² | DIN 53455 |

| Elongation at Break | min. 300 | % | DIN 53455 |

| Impact Strength (Notched) | No Break | Kj/m² | DIN 53453 |

| Impact Strength (Charpy, Notched) | min. 210 | Kj/m² | ISO 11542/2 |

| Coefficient of Friction | 0.1 - 0.15 | — | — |

| Hardness | 60 - 68 | Shore D | DIN 53505 |

| Value | Units | Test Method / Conditions | |

| Density | 0.94 | g/cm³ | DIN 53479 |

| Molecular Weight | min. 4,000 | g/mol | DIN 53728-T |

| Water Absorption | 0 | % | ASTM D570 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature | 130 - 138 | °C | ISO 3146 |

| Minimum Allowable Service Temperature in Air – Continuous | -269 | °C | — |

| Maximum Allowable Service Temperature in Air – Continuous | 90 | °C | — |

| Coefficient of Linear Thermal Expansion | 2x10^-4 | °C-1 | DIN 53752 |

| Value | Units | Test Method / Conditions | |

| Electric Strength | 900 | KV/cm | DIN 53481 |

Technical Details & Test Data

- Technical Info

Standard Ulpolen1000® is the universal type primarily preferred on the condition that its technical properties meet operating environment requirements. It is more cost efficient compared to special types with additives. One major problem in the identification and selection of materials is the difficulty in distinguishing Ulpolen1000®(PE1000)from other lower quality polyethylene types in terms of physical apperance. The main differences in technical properties are evidenced in laboratory tests. Variations of Ulpolen1000® (PE1000) within its group according to molecular weights and its physical similarity to other polyethylene types are vital factors that should be carefully studied to select the right material for the application. In addition to “1000” quality, there are subgroups with different technical properties such as Ulpolen® 500 which is primarily used in food industry as cutting plates (with 0.5 million molecular weight).

It is possible to improve Ulpolen1000®'s technical properties through additives depending on the application. Additives inevitibly increase cost, but when life time of material and initial lining effort are considered, advantages of selecting the right material become evident.- Ulpolen®UV, Antistatic

- Ulpolen® Flame Retardant

- Ulpolen® Oil