Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Pharma & Nutraceuticals Functions

- Technologies

- Product Families

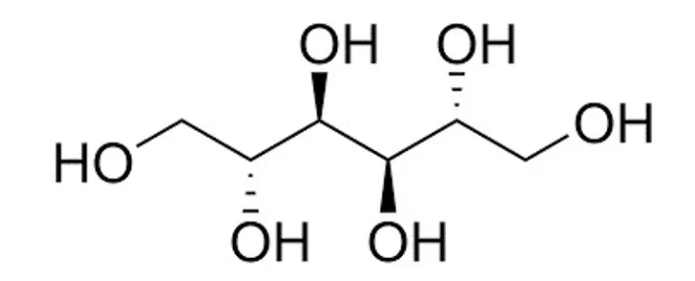

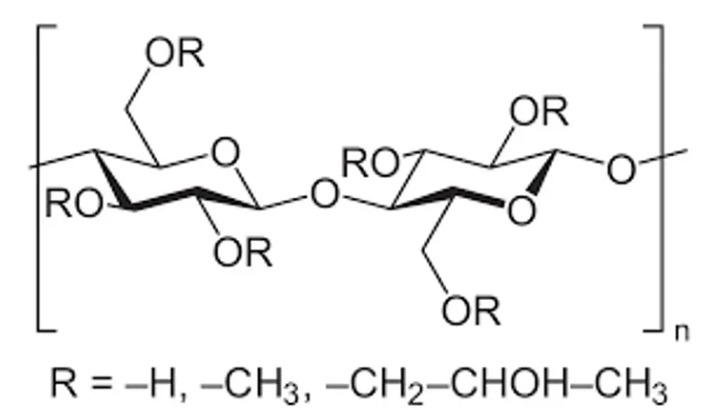

- Chemical Structure

Mannitol Hydroxypropyl methylcellulose

- Morphology

Features & Benefits

- Key Attributes

- Uses multicompendial ingredients

Applications & Uses

- Applications

- Manufacturing Technology

- Product Applications

PEARLITOL® CR-H co-processed mannitol HPMC is a direct compression excipient providing functional properties of binder as well as controlled release to your tablet. PEARLITOL® CR-H can be used in both pharmaceutical and nutraceutical oral dosage forms.

Properties

- Physical Form

- Appearance

- White to yellowish-white powder or granules

- Odor

- Neutral taste, slightly sweet

- Partially Soluble in

- Cold water

- Typical Properties

- Microbiological Values

- Particle Size Distribution

| Value | Units | Test Method / Conditions | |

| Loss On Drying | max. 4.0 | % | — |

| pH | 5 - 8 | — | — |

| D-Mannitol (as is) | 25 - 35 | % | — |

| Hypromellose (as is) | 65 - 75 | % | — |

| Sulfated Ash | max. 1.0 | % | — |

| Bulk Density | 300 - 500 | g/l | — |

| Molecular Weight | 182.2 | g/mol | — |

| Water Content | max. 4 | % | — |

| Average Mean Particle Diameter | 150.0 | µm | — |

| Particle Size Distribution (dv10) | 60.0 | µm | Laser Diffraction |

| Particle Size Distribution (dv50) | 140.0 | µm | Laser Diffraction |

| Particle Size Distribution (dv90) | 290.0 | — | Laser Diffraction |

| Melting Temperature | 165 - 170 | °C | — |

| Powder Flowability | 12.0 | seconds | — |

| Tapped Density | 0.43 | g/cm³ | — |

| True Density | 1.456 | g/cm³ | — |

| Specific Surface Area | 0.8 | m²/g | — |

| Value | Units | Test Method / Conditions | |

| Total Aerobic Microbial Count | max. 1000 | CFU/g | — |

| Total Yeasts and Molds Count | max. 100 | CFU/g | — |

| Escherichia Coli | Not detected | in 1g | — |

| Salmonella | Not detected | in 10g | — |

| Value | Units | Test Method / Conditions | |

| Particle (more than 500microns) | max. 5 | % | Laser |

| Particle (more than 315 microns) | max. 25 | % | Laser |

| Particle (more than 40 microns) | min. 90 | % | Laser |

Regulatory & Compliance

- Certifications & Compliance

- Grade

- Conformity

Meets the requirements of the current monograph of

- European Pharmacopeia MANNITOL (0559) and HPMC

- USP-NF Pharmacopeia MANNITOL and HPMC

- Japanese Pharmacopeia D-MANNITOL and HPMC

- Chinese Pharmacopeia MANNITOL and HPMC

Please contact us for any statement regarding compliance to the General Chapters (elemental impurities, residual solvents, organic volatile impurities, metal catalyst, metal reagent).

Technical Details & Test Data

- Product Test Data

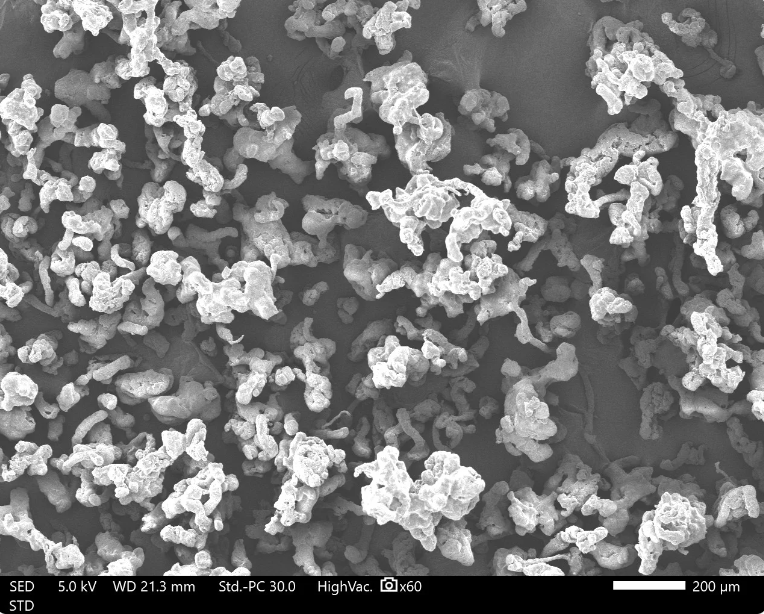

Water sorption isotherm at 20°C

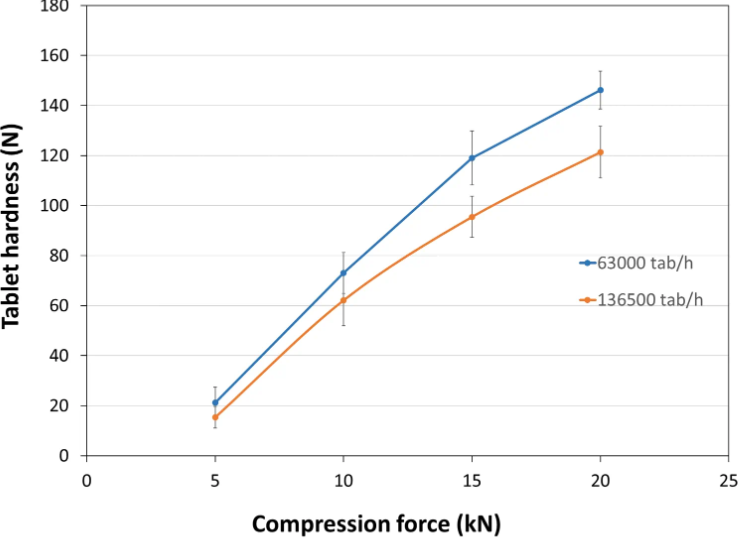

Tablet Hardness

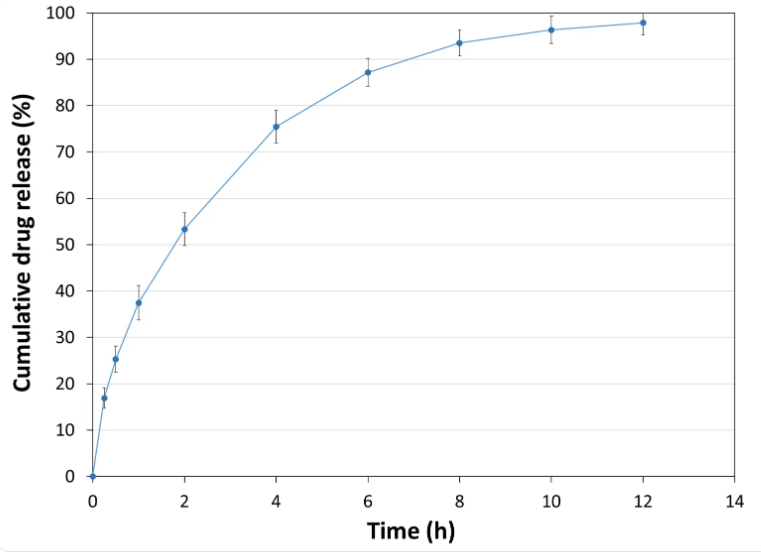

API Release Kinetics

- Experimental Conditions for Compression Behavior

Tablet Press: STYLONE EVO

Production Speed:

30 and 65 RPM (linear punch velocity: 49 and 91 mm/s; simulated KORSCH XL-400 rotary press speed: 63,000 and 136,500 tablets/hour)

Tooling: Diameter 13 mm flat

Formula: PEARLITOL® CR-H / external lubrication with magnesium stearate

Tablet Mass: 400 mg- Experimental Conditions for Sustained Release Behavior

Tablet press: STYL'ONE EVO

Production speed: 30 RPM (linear punch velocity: 49 mm/s; simulated KORSCH XL-400 rotary press speed: 63,000 tablets/hour)

Tooling: Diameter 13 mm flat

Formula: 50% Metformin / 49% PEARLITOL® CR-H / 1% magnesium stearate

Tablet mass: 1,000 mg

Tablet hardness: 109 N

Tablet thickness: 6.8 mm

Dissolution bath: USP II with helical sinker

Release media: pH transition method adapted from US <711> Dissolution Method A

Storage & Handling

- Shelf Life

- 3 years

- Storage Condition

- Manufacturing date: 3 years, in its unopened packaging.

- These dates are indicative and may vary according to packaging type and manufacturing plant. Proper information is shown on labeling and CoA.

- We recommend to preserve the product in its unopened original packaging, preferably protected from wide variations of temperature and humidity.

- Upon opening, use the product as quickly as possible to prevent moisture regain.