Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Application Method

- B-stage Procedure

Apply adhesive to substrate. Apply heat to advance curing to the non-tacky stage (when cooled to room temperature). A temperature of 125°C for 2 – 3 minutes is required (B-stage time is mass related). The user is encouraged to experiment for optimum drying time at a given temperature. Store on release liner to prevent contamination.

- Bonding Procedure

To use, carefully align parts to be bonded, apply uniform pressure to maintain location. Follow curing guidelines given above. Timing should start once adhesive and substrate reach curing temperature.

Properties

- Typical Properties

- Uncured Properties

- Typical Cured Properties

| Value | Units | Test Method / Conditions | |

| Pot Life | Latent | - | - |

| Conductivity | 5.5 | W/mK | - |

| Chloride | max. 10 | ppm. | - |

| Sodium Content | max. 10 | ppm. | - |

| Potassium Content | max. 10 | ppm. | - |

| Value | Units | Test Method / Conditions | |

| Brookfield Viscosity - HAT Viscometer (at 10 rpm at 25°C) | 23000 | cps | - |

| Specific Gravity | 1.85 | water = 1 | - |

| Theoretical Coverage (at 0.001" Thickness) | 30 | in^2 | - |

| Screen Life | 8 | hrs | - |

| Solid Content | 87 | % | - |

| Value | Units | Test Method / Conditions | |

| Thermal Conductivity | 5.5 | W/mK | - |

| Dielectric Strength | 440 | volts/mil | - |

| Volume Resistivity | 1 x 10^16 | ohms cm | - |

| Dielectric Constant (at 1 Hz) | 5.2 | - | - |

| Dielectric Factor (60 Hz) | 0.018 | - | - |

| Thermal Stability | Good to 325 | °C | - |

| Useful Temperature Range | -55 to 230 | ºC | - |

| Glass Transition Temperature (Tg) | 100 | ºC | - |

| Coefficient of Thermal Expansion below Tg | 29.5 x 10^-6 | in/in/ºC | - |

| Coefficient of Thermal Expansion above Tg | 13.5 x 10^-5 | in/in/°C | - |

| Dynamic Tensile Modulus (at -65°C) | 8780 | Mpa | - |

| Dynamic Tensile Modulus (at 25°C) | 6710 | Mpa | - |

| Dynamic Tensile Modulus (at 150°C) | 182 | Mpa | - |

| Dynamic Tensile Modulus (at 200°C) | 152 | Mpa | - |

| T-Shear Strength | 1800 | psi | - |

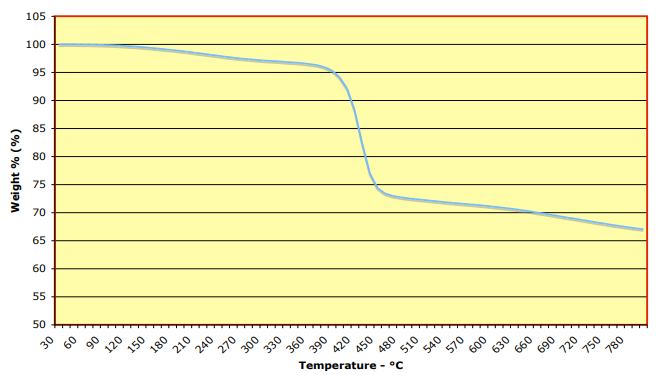

| Weight Loss (at 300°C, TGA) | 2.98 | % | - |

| Differential Scanning Calorimetry (DSC) Peak Tc | 184 | °C | - |

| Differential Scanning Calorimetry (DSC) ∆ Hc | -28.7 | J/g | - |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Test Data

Safety & Health

- Safety & Handling

- Use with adequate ventilation.

- Keep away from sparks and open flames.

- Avoid prolonged contact with skin and breathing of vapors.

- Wash with soap and water to remove fro skin.

Storage & Handling

- Curing Guidelines

These temperatures and times are presented as a guide only. The end-user is encouraged to experiment to determine optimum curing schedule.

Temperature (°C) Time (min.) 150 60 175 30 200 15 - Handling And Storage

122-07(SP) is a one component epoxy system and is ready to use as received. Product should be stored frozen to maintain consistent flow properties. Allow 122-07(SP) to warm up to room temperature before opening container. Prior to using, mix thoroughly to re-suspend fillers. If needed, 122-07(SP) can be thinned with small amounts of Creative Materials’ 113-12 thinner.

Storage Temperature Containers B-Staged Film 25°C 2 months 1 month -10°C 6 months 6 months