Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Advantages

- Qualified and well-known for Vacuum Infusion & RTM process

- High glass transition temperatures : dry*: Tg>200°C; wet*: Tg>160°C

- Low moisture absorption: 2.0 – 3.0 %

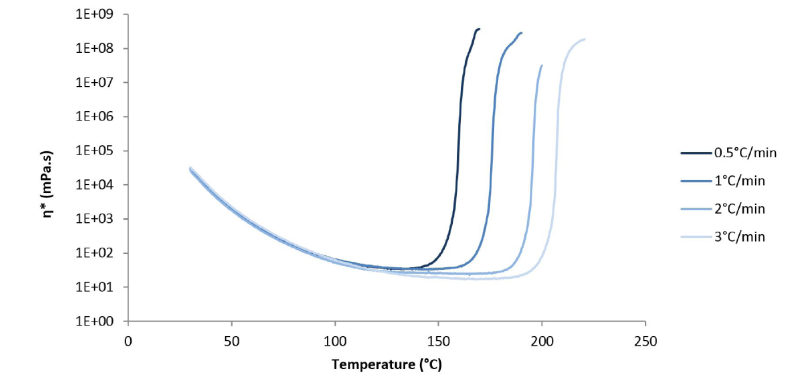

- < 100 mPa.s at process temperatures

- Mechanical properties similar to latest generation prepregs when combined with HiTape® & HiMax™ reinforcements

- Flexible processing and cure cycles

Applications & Uses

- Markets

- Composites Processing Methods

- Processing

- Defrosting: 24h at 23°C ± 5°C (10kg)

- Process parameters (Infusion or RTM):

- Preheat resin at 80°C (please refer to “Hexcel RTM6 Safety Processing Guidelines” document for maximum preheating time)

- Mold temperature: between 120°C and 140°C, at constant temperature

- Injection / infusion lines: 90 – 110°C

- Mold / bagging leakage: below 15 mbar in 5min

- Vacuum Infusion: below 5 mbar

- RTM Piston Pressure: atm to 5 bars

- Cure cycle: 90 min minimum at 180°C - no post cure required (degree of cure: α > 90%)

Properties

- Mechanical Properties

- Laminate properties

- Gel Point

Temperature Gel time: G’ & G’’ crossover Time to reach 1000 mPa.s Time to reach 200 mPa.s (°C) (hh:min) (hh:min) (hh:min) 80 > 15:00 > 15:00 Viscosity > 200mPa.s 90 > 15:00 12:00 100 11:30 8:00 5:30 110 7:30 5:00 4:00 120 4:00 3:00 2:30 130 2:40 2:00 1:40 140 1:40 1:20 1:10 150 1:00 0:55 0:50 160 0:45 0:40 0:35 170 0:30 0:25 0:25 180 0:20 0:20 0:15 - DMA (EN6032)

Tg (°C) Dry Wet Onset 210 175 Loss 215 190 Tanδ 230 195 - Testing Conditions

Uncured resin data

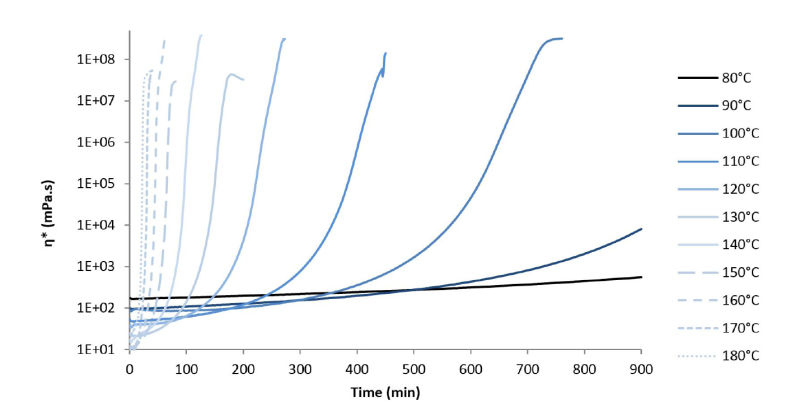

Isothermal viscosities: EN6043

- Gap: 0.5mm

- Shear rate: 10 rad/s

- Strain: 4%

Rheology profile: EN6043

- Gap: 0.5mm

- Shear rate: 10 rad/s

- Strain: 4%

- Temperature range: from 30°C to 250°C

Cured resin data

K1c: ASTM D5045

Density: ISO1183

DMA: EN6032

- Mode: fixed frequency, simple cantilever

- Amplitude: 15µm

- Frequency: 1Hz

- Heating rate: 3°C/min

- Temperature range: 30°C to 250°C

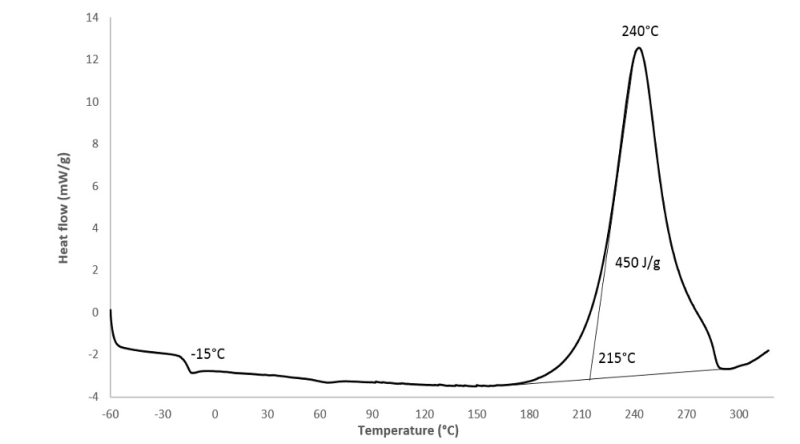

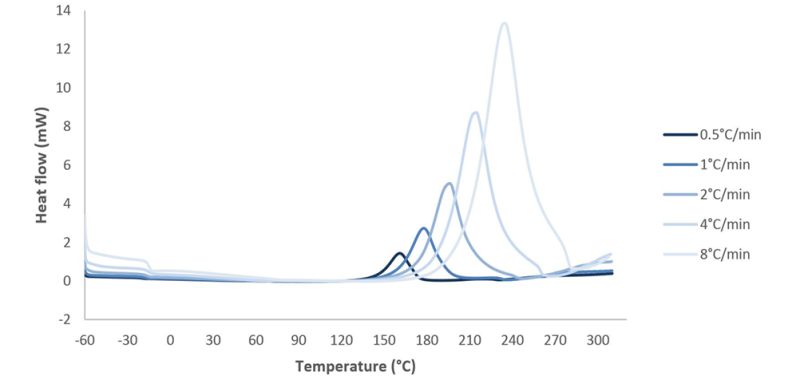

Standard DSC: EN6041

- Heating rate: 10°C/min

- Temperature range: from -60°C to 350°C

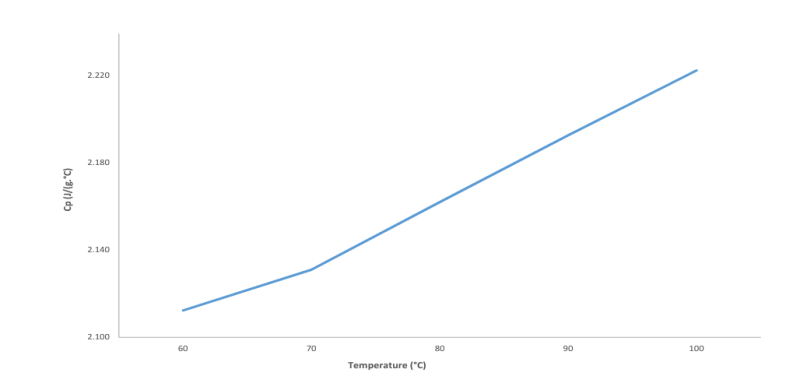

Modulated DSC:

- 2 heating cycles: from -10°C to 110°C then from -50°C to 280°C at 2°C/min, Cp measured on second heating rate

- Oscillation: +/-1°C

- Period: 120s

Compression : ASTM D695

Tensile : ASTM D638

| Value | Units | Test Method / Conditions | |

| K1C (-m½) | 0.6 | MPa | — |

| Density | 1.14 | g/cm3 | — |

| Coefficient of Thermal Expansion -50°C to 20°C | 50 | μm/m°C | — |

| Coefficient of Thermal Expansion 20°C to 100°C | 60 | μm/m°C | — |

| Coefficient of Thermal Expansion 100°C to 180°C | 75 | μm/m°C | — |

| Moisture uptake | 2.0 – 3.0 | % | — |

| Ultimate strength 23°C ± 5°C (Dry) | 320 | MPa | ASTM D695 |

| Ultimate strength 23°C ± 5°C (Wet) | 300 | MPa | ASTM D695 |

| Modulus 23°C ± 5°C (Dry) | 3.2 | GPa | ASTM D695 |

| Modulus 23°C ± 5°C (Wet) | 3.1 | GPa | ASTM D695 |

| Ultimate strength 120°C ± 5°C (Dry) | 210 | MPa | ASTM D695 |

| Ultimate strength 120°C ± 5°C (Wet) | 175 | MPa | ASTM D695 |

| Modulus 120°C ± 5°C (Dry) | 2.8 | GPa | ASTM D695 |

| Modulus 120°C ± 5°C (Wet) | 2.3 | GPa | ASTM D695 |

| Ultimate strength 23°C ± 5°C (Dry) | 90 | MPa | ASTM D638 |

| Ultimate strength 120°C ± 5°C (Wet) | 40 | MPa | ASTM D638 |

| Modulus 23°C ± 5°C (Dry) | 3 | MPa | ASTM D638 |

| Modulus120°C ± 5°C (Wet) | 1.9 | MPa | ASTM D638 |

| Value | Units | Test Method / Conditions | |

| Compression 0°, Modulus (120°C ± 5°C, Dry) | 62 | GPa | EN2850A1 |

| Compression 0°, Modulus (120°C ± 5°C, Wet) | 63 | GPa | EN2850A1 |

| Compression 0°, Modulus (23°C ± 5°C, Dry) | 59.1 | GPa | EN2850A1 |

| Compression 0°, Modulus (23°C ± 5°C, Wet) | 62.2 | GPa | EN2850A1 |

| Compression 0°, Ultimate strength (120°C ± 5°C, Dry) | 550 | MPa | EN2850A1 |

| Compression 0°, Ultimate strength (120°C ± 5°C, Wet) | 430 | MPa | EN2850A1 |

| Compression 0°, Ultimate strength (23°C ± 5°C, Dry) | 710 | MPa | EN2850A1 |

| Compression 0°, Ultimate strength (23°C ± 5°C, Wet) | 540 | MPa | EN2850A1 |

| Compression 90°, Modulus (120°C ± 5°C, Dry) | 60 | GPa | EN2850A1 |

| Compression 90°, Modulus (120°C ± 5°C, Wet) | 61 | GPa | EN2850A1 |

| Compression 90°, Modulus (23°C ± 5°C, Dry) | 60.7 | GPa | EN2850A1 |

| Compression 90°, Modulus (23°C ± 5°C, Wet) | 61 | GPa | EN2850A1 |

| Compression 90°, Ultimate strength (120°C ± 5°C, Dry) | 530 | (MPa) | EN2850A1 |

| Compression 90°, Ultimate strength (120°C ± 5°C, Wet) | 640 | (MPa) | EN2850A1 |

| Compression 90°, Ultimate strength (23°C ± 5°C, Dry) | 640 | (MPa) | EN2850A1 |

| Compression 90°, Ultimate strength (23°C ± 5°C, Wet) | 530 | (MPa) | EN2850A1 |

| Compression after Impact, Delaminated Area (23°C ± 5°C, Dry, 30J impact) | 970 | (mm²) | ASTM D7136/ D7137 |

| Compression after Impact, Indent Depth (23°C ± 5°C, Dry 30J impact) | 0.5 | (mm) | ASTM D7136/ D7137 |

| Compression after Impact Gross Strength (23°C ± 5°C, Dry 30J impact) | 215 | MPa | ASTM D7136/ D7137 |

| In Plane Shear, Modulus (120°C ± 5°C, Dry) | 3.4 | GPa | EN6031 |

| In Plane Shear, Modulus (120°C ± 5°C, Wet) | 2.9 | GPa | EN6031 |

| In Plane Shear, Modulus (23°C ± 5°C, Dry) | 3.8 | GPa | EN6031 |

| In Plane Shear, Modulus (23°C ± 5°C, Wet) | 4.1 | GPa | EN6031 |

| In Plane Shear, Ultimate Strength (120°C ± 5°C, Dry) | 85 | MPa | EN6031 |

| In Plane Shear, Ultimate strength (120°C ± 5°C, Wet) | 70 | MPa | EN6031 |

| In Plane Shear, Ultimate strength (23°C ± 5°C, Dry) | 115 | MPa | EN6031 |

| In Plane Shear, Ultimate strength (23°C ± 5°C, Wet) | 95 | MPa | EN6031 |

Technical Details & Test Data

- Uncured Resin Properties

Viscosity

Figure 1: Rheology profile of HexFlow® RTM6 resin

Figure 1: Rheology profile of HexFlow® RTM6 resin

Figure 2: Rheology profile of HexFlow® RTM6 resin

- Thermokinetics

Standard DSC parameters

Tg midpoint (°C) Enthalpy (J/g) T peak (°C) T onset (°C) -15 450 240 215  Figure 3: Standard DSC HexFlow® RTM6 resin

Figure 3: Standard DSC HexFlow® RTM6 resin

Figure 4: Specific heat of HexFlow® RTM6 resin

Figure 5: Standard DSC at various heating rates of HexFlow® RTM6 resin

Storage & Handling

- Shelf Life

- 15 days (20 - 26°C), 9 months (-18°C)