Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Attributes

- Thermal conductivity of 1.0 W/(m·K)

- 1:1 mix ratio

- Working life: 4 minutes

- Set time: 15 minutes

- Cure time: 4 hours at room temperature or 10 minutes at 65 °C (149 °F)

- Flame retardant—meets UL 94V-0 standard

- Provides strong electrical insulation

- Low CTE prior Tg

- High tensile and compressive strength

- Strong resistance to humidity, salt water, mild bases, and aliphatic hydrocarbons

- RoHS 3 compliant

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Application Instructions

For best results, follow the procedure below. For quantities less than 1 mL or for stricter stoichiometry control, mix by weight with a high-precision balance. Heat cure to achieve optimal conductivity.

Syringe or Cartridge

To insert the cartridge in the gun, see the Application Guide section for dispensing accessories.

- Twist and remove the cap from the cartridge or syringe. Do not discard cap.

- Dispense a small amount to ensure even flow of both parts.

- (Optional) Attach a static mixer.

- a. Dispense and discard 3 to 5 mL of the product to ensure a homogeneous mixture.

- b. After use, dispose of static mixer.

- Without a static mixer, dispense material on a mixing surface or container, and thoroughly mix parts A and B together.

- To stop the flow, pull back on the plunger.

- Clean nozzle to prevent contamination and material buildup.

- Replace the cap on the cartridge or syringe.

Dispensing Accessories

Consult the table below for appropriate accessory selection. See the Application Guide for instructions on using the dispensing accessories

Cat. No. Dispensing Gun Static Mixer 8329TCF-50ML 8DG-50-1-1 N/A - Compatibility

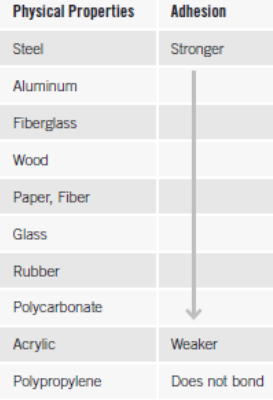

Adhesion - 8329TCF epoxy adheres to most plastics and metals used to house printed circuit assemblies; however, it is not compatible with contaminants like water, oil, or greasy flux residues, which may affect adhesion. In case of contamination, first, clean the surface to be coated with MG Chemicals 824 Isopropyl Alcohol. For substrate substances with weak adhesion strengths, surface preparation such as sanding or pre-coating with a suitable primer may improve adhesion.

Chemical resistance - Once cured, the epoxy adhesive is inert under normal conditions. It will resist water and salt exposure. It is expected to resist short term exposures to fuels or similar non-polar organic solvents, but it is not suitable for prolonged exposures. Avoid use with strong acids, strong bases, or strong oxidizers.

Substrate Adhesion (In Decreasing Order)

Properties

- Physical Form

- Physical Properties

- Thermal Properties

- Typical Properties

- Electrical Properties

- Cured Properties

- Uncured Properties

- Note

Physical Properties

- Note : Specifications are for epoxy samples cured at 22 °C for 24 h and conditioned at ambient temperature and humidity.

- a) N/mm2 = mPa; lb/in2 = psi

Electrical Properties and Thermal Properties

- Note : Specifications are for epoxy samples cured at 22 °C for 24 h and conditioned at ambient temperature and humidity.

- a) To allow comparison between products, the dielectric strength was recalculated with the Tautscher equation fitted to 5 experimental values and extrapolated to a standard thickness of 1/8” (3.175 mm).

- b) Coefficient of Thermal Expansion (CTE) units are in ppm/°C = in/in/°C × 10-6 = unit/unit/°C × 10-6

Uncured Properties :Mixture (A:B)

- Reference fit

- a) To allow comparison between products, the dielectric strength was recalculated with the Tautscher equation fitted to 5 experimental values and extrapolated to a standard thickness of 1/8” (3.175 mm).

- b) Coefficient of Thermal Expansion (CTE) units are in ppm/°C = in/in/°C × 10-6 = unit/unit/°C × 10-6

- Physical Properties

Physical Properties Part A Part B Color White Slight yellow Viscosity (25 °C [77 °F]) 9500000 cP [9500 Pa·s] a) 800000 cP [800 Pa·s] b) Density 1.88 g/mL 1.59 g/mL Odor Mild Mercaptan - a) Brookfield viscometer at 1 rpm with spindle RV F96

- b) Brookfield viscometer at 1 rpm with spindle RV C93

| Value | Units | Test Method / Conditions | |

| Color | Off white | — | — |

| Density (at 25 °C, 77 °F) | 1.75 | g/mL | ASTM D 1475 |

| Young’s Modulus | 1700 (250000) | N/mm2 ( lb/in2) | ASTM D 638 |

| Lap Shear Strength (Stainless Steel) | 5.0 (700) | N/mm2 (lb/in2) | ASTM D 1002 |

| Lap Shear Strength (Aluminum) | 8.6 (1 200) | N/mm2 (lb/in2) | ASTM D 1002 |

| Lap Shear Strength (Copper) | 13 (1900) | N/mm2 (lb/in2) | ASTM D 1002 |

| Lap Shear Strength (Brass) | 14 (2 100) | N/mm2 (lb/in2) | ASTM D 1002 |

| Lap Shear Strength (Polycarbonate) | 1.5 (220) | N/mm2 (lb/in2) | ASTM D 1002 |

| Lap Shear Strength (ABS) | 2.0 (300) | N/mm2 (lb/in2) | ASTM D 1002 |

| Flammability | Meets 94 V-0 | UL 94 | — |

| Viscosity | Thixotropic | — | — |

| Density | 1.73 | g/mL | — |

| Value | Units | Test Method / Conditions | |

| Thermal Conductivity (at 25 °C, 77 °F) | 1 | W/(m·K) | ASTM E 1461 92 |

| Thermal Conductivity (at 50 °C, 222 °F) | 1 | W/(m·K) | ASTM E 1461 92 |

| Thermal Conductivity (at 100 °C, 212 °F) | 0.9 | W/(m·K) | ASTM E 1461 92 |

| Thermal Diffusivity (at 25 °C, 77 °F) | 0.4 | mm2/s | ASTM E 1461 92 |

| Specific heat capacity @25 °C [77 °F] | 1.3 | J/(g·K) | ASTM E 1461 92 |

| Value | Units | Test Method / Conditions | |

| Mix Ratio | 1:1 | Volume | — |

| Mix Ratio | 1:0.9 | Weight | — |

| Value | Units | Test Method / Conditions | |

| Breakdown Voltage (at 2.1 mm) | 35300 (35.3) | V (kV) | ASTM D 149 |

| Dielectric Strength (at 2.1 mm) | 412 (16.2) | kv/mm (v/mil) | ASTM D 149 |

| Breakdown Voltage (at 3.175 mm, 1/8") | 42700 (42.7) | V (kV) | Reference fit |

| Dielectric strength (at 3.175 mm, 1/8") | 342 (13.1) | kv/mm (v/mil) | Reference fit |

| Volume Resistivity | 3 x 10¹² | Ω·cm | ASTM D 257 |

| Volume Conductivity | 3.3 x 10⁻¹³ | S/cm | ASTM D 257 |

| Value | Units | Test Method / Conditions | |

| Hardness Shore D | 82 | — | Shore D Durometer |

| Tensile Strength | 13 (1900) | N/mm2 (lb/in2) | ASTM D 638 |

| Compressive Strength | 48 (7000) | N/mm2 | ASTM D 695 |

| Glass Transition Temperature (Tg) | 23 (73) | °C (°F) | ASTM E 3418 |

| CTE Prior Tg | 23 (73) | ppm/˚C (ppm/°F) | ASTM E 831 |

| CTE After Tg | 107 (225) | ppm/˚C (ppm/°F) | ASTM E 831 |

| Value | Units | Test Method / Conditions | |

| Solids Content | 100 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Usage Parameters

Properties Value Working life (22 °C [72 °F]) 4 min Shelf life (22 °C [72 °F]) ≥3 y Set time (22 °C [72 °F]) 15 min Full cure (22 °C [72 °F]) 4 h Full cure (65 °C [149 °F]) 10 min Full cure (80 °C [176 °F]) 5 min

Packaging & Availability

- Packaging Type

- Packaging and Supporting Products

Cat. No. Packaging Net Volume Net Weight Packaging Weight

8329TCF-50ML Dual cartridge 78 g [1.52 fl oz] 45 mL [1.52 fl oz] 111 g [0.25 lb]

Storage & Handling

- Temperature Ranges

Properties Value Constant service temperature -40 to 150 °C [-40 to 302 °F] Maximum Intermittent temperature a) 175 °C [347 °F] Storage temperature 22 to 27 °C [72 to 81 °F] - a) Temperature that can be withstood for short periods without sustaining damage.