Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Polyglycerol Polyricinoleate

- Food Additive Number

- E 476, INS 476

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Food Ingredients Features

- Advantages

Molding Chocolate

- Easier removal of air bubbles during vibration process.

- Uniform distribution of chocolate in molds and better coating of inclusions.

- Easier chocolate flow along pipes.

Enrobing Chocolate

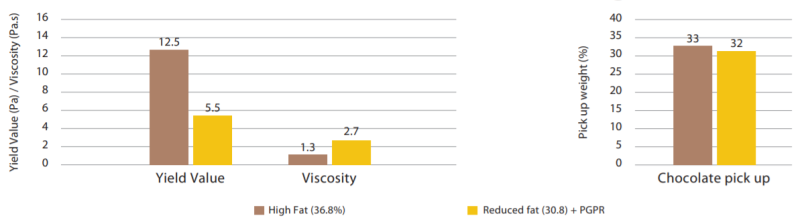

- Lower enrobing viscosity to achieve desired pick up weight.

- Enable excess chocolate layer to be blown and reworked.

- Formulate up to 6% fat reduction in recipe for cost savings and healthier option.

Ice Cream Dipping Chocolate

- Uniform coating of dipping chocolate layer.

- Resistance to moisture contamination from melted ice cream.

- Reduction of pinholes defect in chocolate coating.

- Formulation Considerations While Using MASEMUL® PGPR 9090

- Recommended dosage of 0.1-0.3% MASEMUL® PGPR 9090 and is usually used in combination with lecithin for optimal results.

- Excellent choice especially in fat reduced chocolate and compound chocolate formulations.

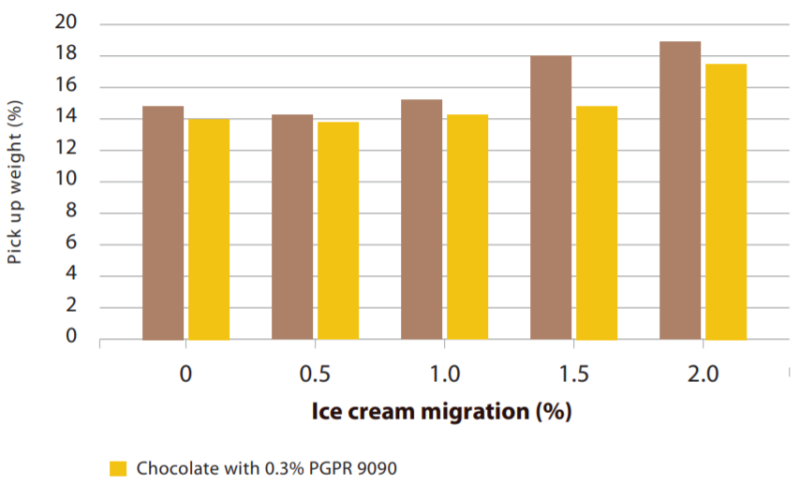

- Uniform dipping chocolate pick up rate by ice cream and overcome negative effects of water migration into ice cream coating.

Applications & Uses

- Markets

- Food & Nutrition Applications

- Use Level

- 0.1 - 0.3%

- Recommended Uses & Known Applications

- 0.1-0.3% basis total wt - Chocolate, compound coatings, ice cream coatings

- Application & Functionality

Tin Greasing Agent

- Excellent release properties.

Compound Chocolate and Ice Cream Coatings

- Lowers viscosity & yield value leading to fat reduction and production process optimisation.

- Ease of production, cost saving.

Low fat spreads/ Bakery compounds

- Strong water binder by stabilizing low-fat spread emulsions.

Properties

- Appearance

- Liquid

- Microbiological Values

- Periodic Testing Parameter

- Specifications

- Heavy Metals

| Value | Units | Test Method / Conditions | |

| Coliforms (in 1g) | Absent | — | — |

| Salmonella (in 25g) | Absent | — | — |

| Total Plate Count | max. 5000 | /g | — |

| Yeast and Molds Count | max. 100 | /g | — |

| Value | Units | Test Method / Conditions | |

| Saponification Value | 170 - 210 | mgKOH/g | — |

| Value | Units | Test Method / Conditions | |

| Acid Value | max. 3 | mg KOH/g | — |

| Hydroxyl Value | 80 - 100 | mgKOH/g | — |

| Iodine Value | 72 - 103 | gI2/100g | — |

| Value | Units | Test Method / Conditions | |

| Arsenic Content | max. 3 | ppm | — |

| Cadmium Content | max. 1 | ppm | — |

| Heavy Metals (as Pb) | max. 10 | ppm | — |

| Lead Content | max. 1 | ppm | — |

| Mercury Content | max. 1 | ppm | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Information

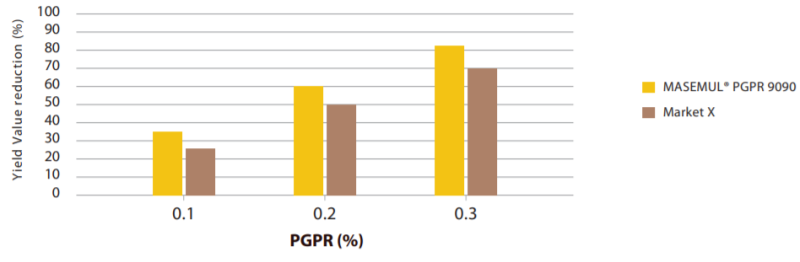

MASEMUL® PGPR 9090 in molding chocolate

- Reduces yield value effectively – use in small dosage with superior performance.

- At 0.2%, will typically show a yield value reduction of ~60%.

Yield Value reduction in chocolate by PGPR

MASEMUL® PGPR 9090 in reduced fat enrobing chocolate

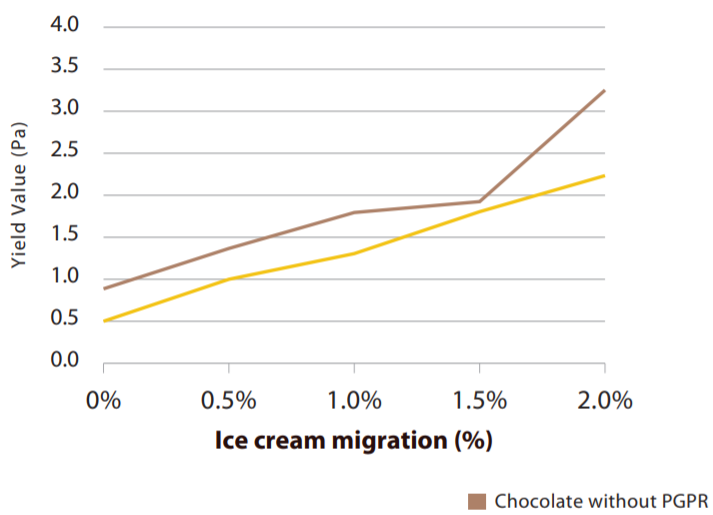

MASEMUL® PGPR 9090 in ice cream chocolate coating

Impact of ice cream migration on yield value of dipping chocolate

Impact of ice cream migration on dipping chocolate pick up weight (%)

MASEMUL® PGPR 9090 provides uniform coating, good control of the chocolate layer and pick up weight in fat reduced formulation. MASEMUL® PGPR 9090 controls thickening or drastic increase in chocolate yield value due to presence of water in dipping chocolate.

Packaging & Availability

- Packaging Information

20kg Jerrycan; 950 kg IBC plastic totes.

Storage & Handling

- Shelf Life

- 24 months

- Shelf Life

24 months from the date of manufacture.

Shelf life is stated as a minimum from date of production when the product is stored in unbroken packaging and provided that the storage conditions stated herein are observed.

- Storage Condition

- The product must be stored in manufacturer's original sealed container

- The product must be stored in a sheltered and well-ventilated warehouse; not exposed to moisture and direct sunlight.