Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Applications

- Sheet

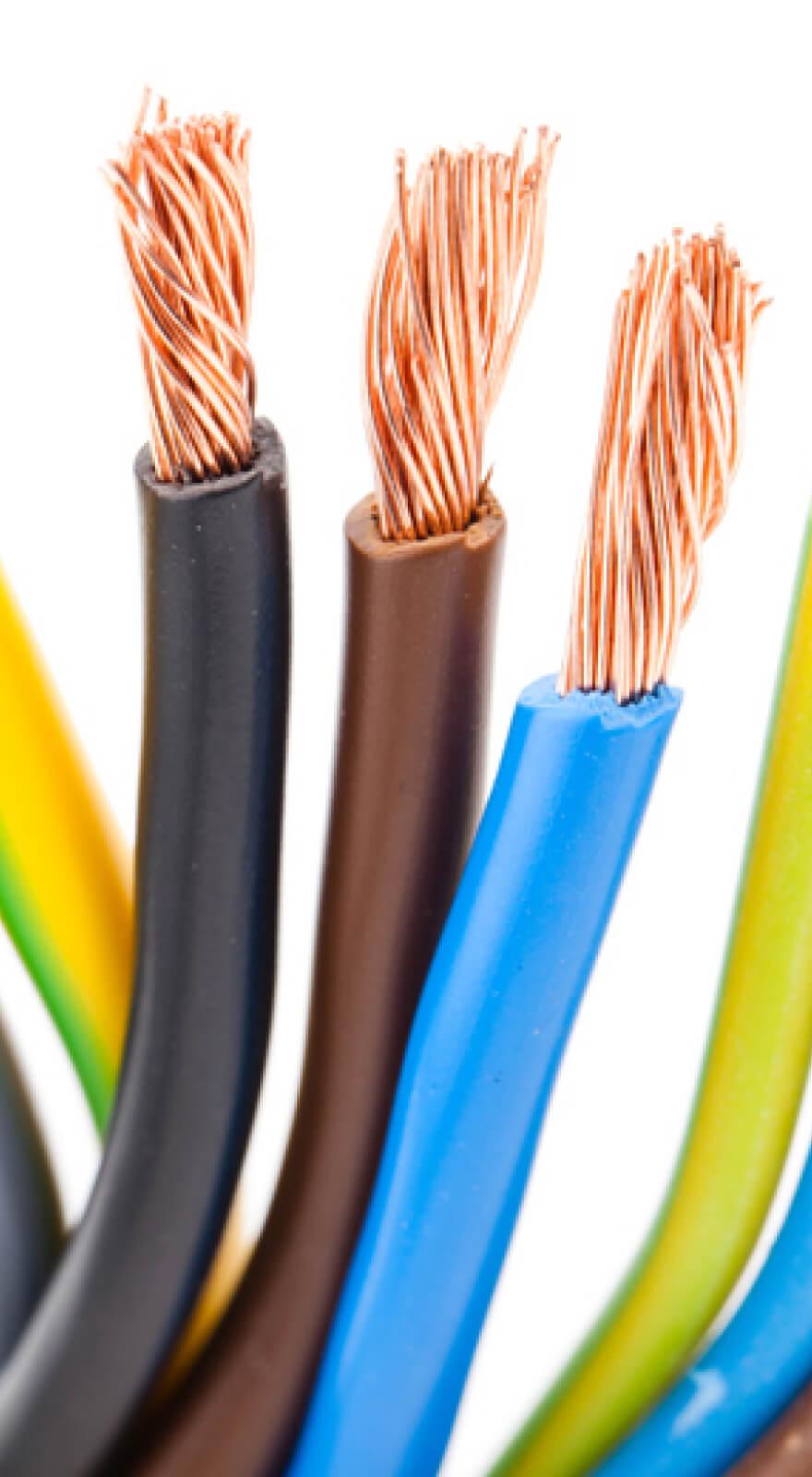

- Tubing

- Jacketing

Properties

- Flame Rating

- Physical Form

- Appearance

- Natural Pellets

- Physical Properties

- Flammability

| Value | Units | Test Method / Conditions | |

| Density | 1.51 | g/cc | ASTM D792 |

| Dissipation Constant (at 1 MHz) | 2.8 | 1 MHz | ASTM D150 |

| Dissipation Constant (at 100 KHz) | 3.2 | 100 KHz | ASTM D150 |

| Dissipation Factor (at 1 MHz) | 0.017 | 1 MHz | ASTM D150 |

| Dissipation Factor (at 100 KHz) | 0.014 | 100 KHz | ASTM D150 |

| Elongation | 155 | % | ASTM D638 |

| Flexural Modulus | 24300 | psi | ASTM D790 |

| Melt Flow Rate | 19 | g/10 min | ASTM D1238 Condition F |

| Low Temperature Brittleness | -25 | °C | ASTM D746 |

| Retained Elongation | 75 | % | ASTM D638 |

| Retained Tensile Strength (Heat Aging: 10 Days at 100°C) | 100 | % | ASTM D638 |

| Oxygen Index | 32 | % | ASTM D2863 |

| Smoldering (NBS) | 150 | Dm (corr) | ASTM E662 |

| Hardness | 93 | Shore A | ASTM D2240 |

| Tear Strength | 340 | ft/lb/in | ASTM D624 |

| Tensile Strength | 2000 | psi | ASTM D638 |

| Value | Units | Test Method / Conditions | |

| Flaming | 35 | Dm (corr) | ASTM E662 |

Regulatory & Compliance

- Certifications & Compliance

- Regulatory Status

EXTINITY® 0103-202 does not carry any FDA/U.S.P. approval for food contact and may not be used for any application for implantation in the human body or where bodily fluids could potentially come in contact with the final product.

Technical Details & Test Data

- Typical Performance

In internal tests, EXTINITY® 0103-202 performed to a V-1 rating for UL-94 vertical testing at thickness from 0.030” to 0.060”, and has a V-0 rating at greater thickness. In addition, this compound has passed UL-94 HB tests at thickness of 0.020” and greater. In specific product architectures, EXTINITY® 0103-202 is used as a jacketing compound in order to achieve a Class I rating in the ASTM E-84 “Steiner Tunnel” test.

- Processing Conditions

EXTINITY® 0103-202 can be processed very easily on a wide range of commercially available extrusion equipment. It can withstand extrusion temperatures up to 425°F, but recommended temperatures are much lower.

A typical temperature profile would be:

Zone #1 Zone #2 Zone #3 Zone #4 Head Die Melt Temp Celsius 149°-160°C 166°-177°C 177°-188°C 177°-188°C 171°-182°C 188°-199°C 182°-193°C Fahrenheit 300°-320°F 330°-350°F 350°-370°F 350°-370°F 340°-360°F 370°-390°F 360°-380°F

Storage & Handling

- Storage and Handling

SACO AEI Polymers recommends that EXTINITY® 0103-202 be stored in an ambient temperature range (40 to 80 degrees Fahrenheit), in its original container and away from moisture and high humidity.