Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Key Characteristics

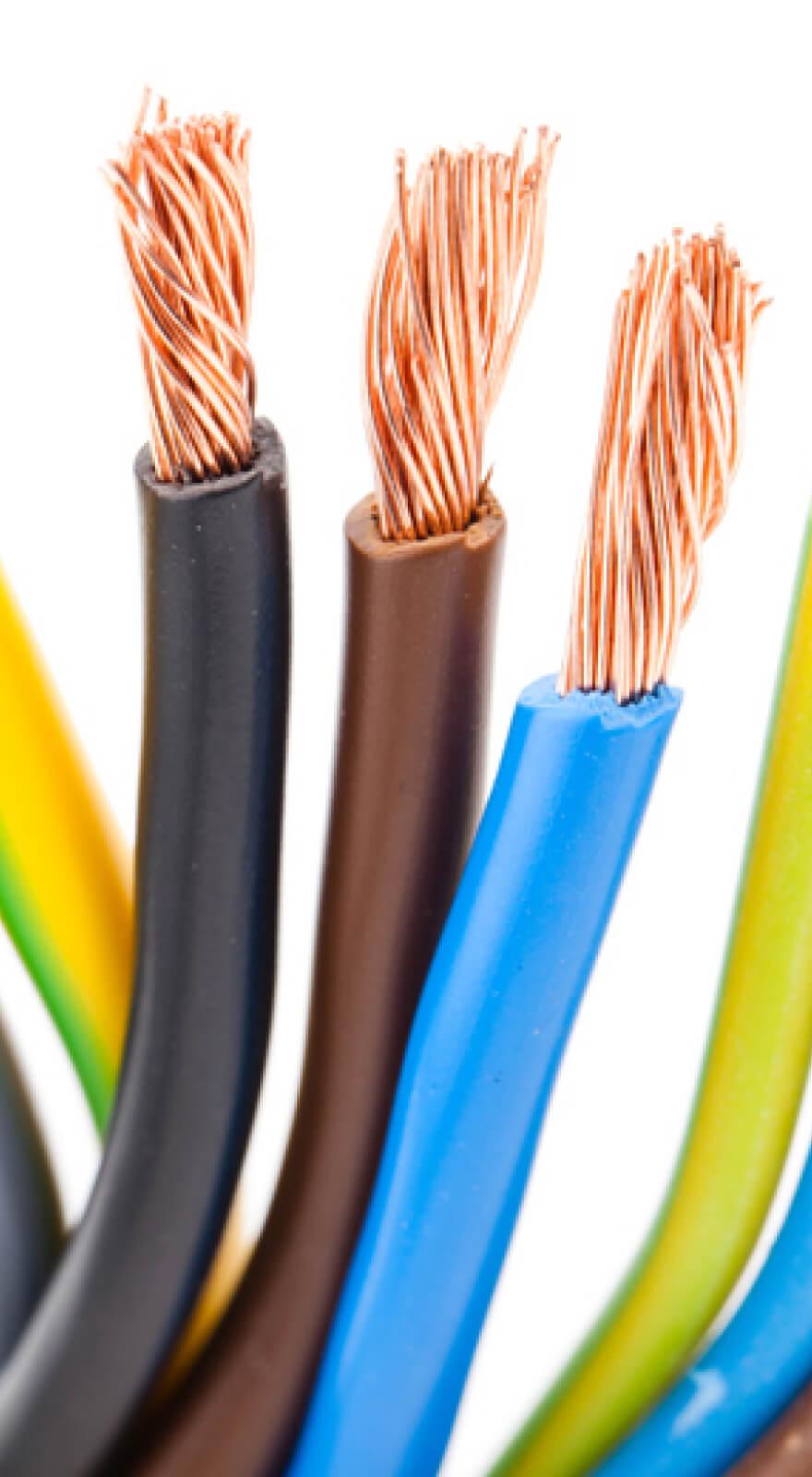

Low smoke, low toxicity, halogen free, flame retardant thermoplastic compound mainly used in cable sheathing applications but also can be used as cable insulation. This compound presents a high hot pressure performance and a high stress crack resistance which allows it to be used as sheathing of any type of armored, large size cables.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers Processing Methods

Properties

- Mechanical Properties

- Physical Properties

- Electrical Properties

- Fire & Smoke Properties

- Thermo-Mechanical Properties

| Value | Units | Test Method / Conditions | |

| Elongation at Break | 180 | % | IEC 60811-501 |

| Elongation at Break (After Thermal Aging: 7 days at 100ºC) | 13 | % Variation | IEC 60811-401 |

| Tensile Strength (at Break) | 13 | N/mm² | IEC 60811-501 |

| Tensile Strength at Break (After Thermal Aging: 7 days at 100ºC) | -10 | % Variation | IEC 60811-401 |

| Value | Units | Test Method / Conditions | |

| Density | 1.48 | g/cm³ | EN ISO 1183-3 |

| Melt Flow Rate (at 150°C / 21.6 kg) | 6 | g/10 min | Internal Method |

| Tear Strength | 7 | N/mm | BS 6469-99.1 |

| Value | Units | Test Method / Conditions | |

| Insulation Constant Ki Resistance (at 20ºC) | 7.7 | MOhm/km | EN 50395 |

| Insulation Constant Ki Resistance (at 90ºC) | 0.057 | MOhm/km | EN 50395 |

| Value | Units | Test Method / Conditions | |

| Halogen Acid Gas Evaluation | max. 0.5 | % | IEC 60754-1 |

| Temperature Index | 270 | °C | BS ISO 4589-3 |

| Temperature Index | 518 | °F | BS ISO 4589-3 |

| Limiting Oxygen Index | 33 | % | BS ISO 4589-2 |

| Value | Units | Test Method / Conditions | |

| Cold Bend (at -50°C) | Pass | No Cracks | IEC 60811-504 |

| Cold Impact (at -30°C) | Pass | — | IEC 60811-506 |

| Elongation at Break: (at -30°C) | 60 (Pass) | % | IEC 60811-505 |

| Hot Pressure Deformation (at 100°C) | 30 | % | IEC 60811-508 |

| Thermal Crack Resistance (at 80°C) | Pass | — | Internal Method |

Technical Details & Test Data

- Processing

Extruder - An extruder with an L/D ratio (length/diameter) between 15 and 24 and a screw with a compression ratio 1.2:1 are recommended.

Extruder temperature conditions: It is important that the melt temperature is not allowed to increase above 160°C. As a guide the following temperature profile is recommended:Zone #1 Zone #2 Zone #3 Zone #4 Head Die Celsius 130°C 140°C 145°C 150°C 160°C 160°C Fahrenheit 266°F 284°F 293°F 302°F 320°F 320°F This profile will vary slightly depending on extruder type, head design and output.

Screw Water Temperature: Not mandatory, if present we recommend 40°-60°C

Recommended Screen Pack: Spacer ring or breaker plate onlyHead & Tool Design - The head and tools should be so designed as to allow streamlined flow of material. To obtain the optimum in physical properties in the case of tubing tools, a maximum drawdown ratio of 1.5:1 is recommended to avoid internal stresses.

Color Masterbatches - EVA, preferable, and PE based color masterbatches including black, up to a maximum of 1%, have no detrimental effect on the properties. It is recommended that all masterbatches should be thoroughly dried before use for 8 hours at 60°C or 4 hours at 80°C in a de-humidifying drier.

Packaging & Availability

- Packaging

The following possibilities are available:

- Moisture resistant sacks containing 25kg

- Boxes with a moisture resistant heat sealed liner containing approximately 600kg

Storage & Handling

- Storage & Shelf Life

TP52NU has an unlimited shelf life. However, the following precautions should be observed:

- Packaging should remain sealed

- Avoid storage outside and in direct sunlight.