Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Key Characteristics

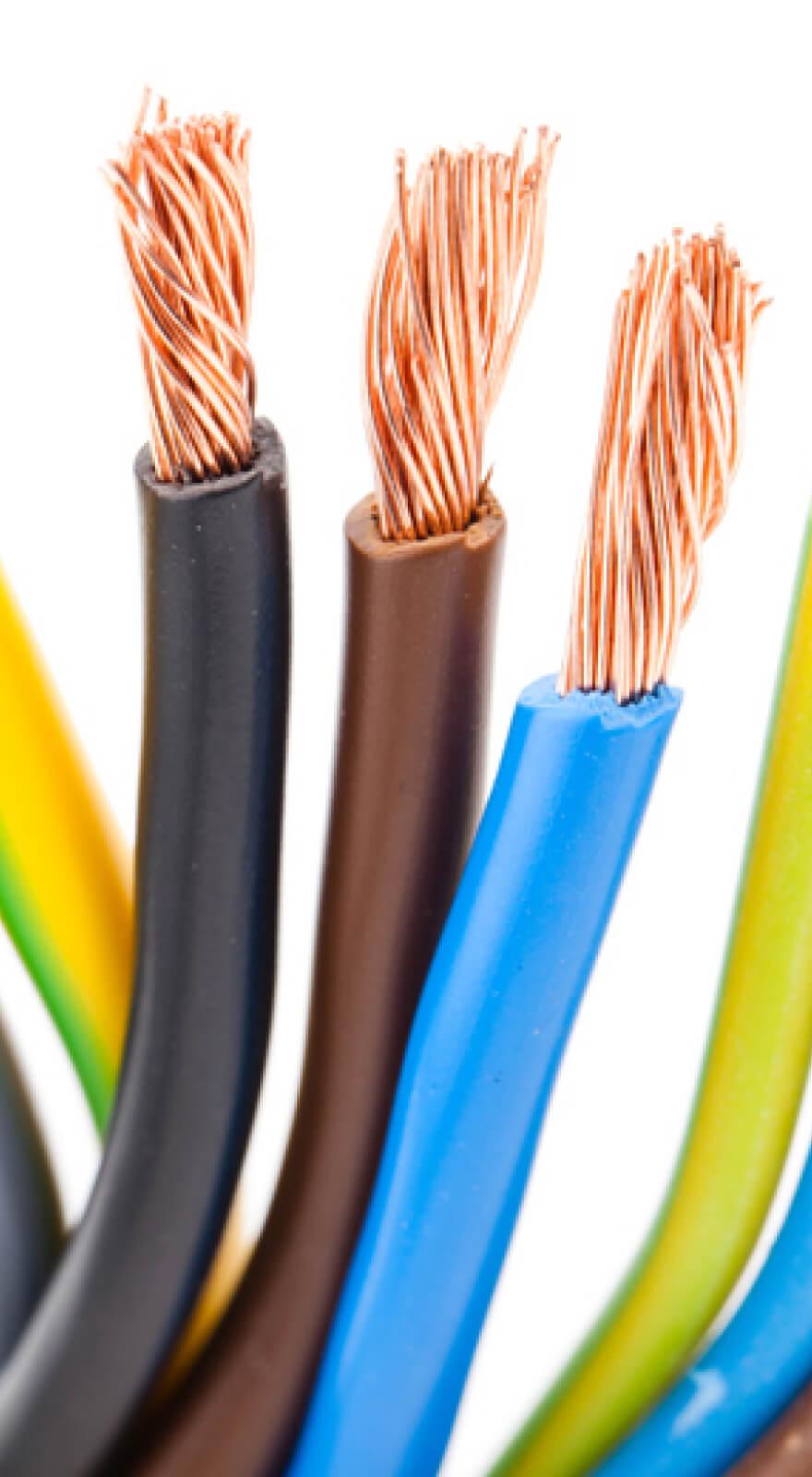

Low smoke, low toxicity, halogen free, flame retardant thermoplastic compound with an interesting fire performance, mainly used in data and communication cables. Can also be used in LV power cable insulation and small diameter cable sheathing.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers Processing Methods

Properties

- Color

- Appearance

- Pellets

- Mechanical Properties

- Physical Properties

- Fire & Smoke Properties

- Thermo-Mechanical Properties

| Value | Units | Test Method / Conditions | |

| Elongation at Break | 165 | % | IEC 60811-501 |

| Elongation at Break (After Thermal Aging: 7 days at 110ºC) | -10 | % Variation | IEC 60811-401 |

| Tensile Strength (at Break) | 12 | N/mm² | IEC 60811-501 |

| Elongation at Break: (at -15°C) | 50 (Pass) | % | IEC 60811-505 |

| Tensile Strength (After Thermal Aging: 7 days at 110ºC) | 12 | % Variation | IEC 60811-401 |

| Value | Units | Test Method / Conditions | |

| Density | 1.52 | g/cm³ | BS EN ISO 1183-3 |

| Melt Flow Rate (at 150°C / 21.6kg) | 13 | g/10 min | Internal Method |

| Tear Strength | 5 | N/mm | BS 6469-99.1 |

| Value | Units | Test Method / Conditions | |

| Halogen Acid Gas Evaluation | max. 0.5 | % | IEC 60754-1 |

| Smoke Emission 3m³ | Pass | — | BS EN 61034-2 |

| Limiting Oxygen Index | 40 | % | BS ISO 4589-2 |

| Value | Units | Test Method / Conditions | |

| Cold Bend (at -15°C) | Pass | No Cracks | IEC 60811-504 |

| Cold Impact (at -15°C) | Pass | — | IEC 60811-506 |

| Hot Pressure Deformation (at 80°C) | 15 | % | IEC 60811-508 |

Technical Details & Test Data

- Processing Conditions

Extruder : An extruder with an L/D ratio (length/diameter) between 15 and 24 and a screw with a compression ratio 1.2:1 are recommended.

Extruder Temperature Conditions: It is important that the melt temperature is not allowed to increase above 160°C.

As a guide the following temperature profile is recommended:Zone #1 Zone #2 Zone #3 Zone #4 Head Die Celsius 130°C 140°C 145°C 150°C 160°C 160°C Fahrenheit 266°F 284°F 293°F 302°F 320°F 320°F This profile will vary slightly depending on extruder type, head design and output.

Screw Water Temperature: Not mandatory, if present we recommend 40°-60°C RECOMMENDED SCREEN PACK: Spacer ring or breaker plate only

Head & Tool Design: The head and tools should be so designed as to allow streamlined flow of material. To obtain the optimum in physical properties in the case of tubing tools, a maximum draw down ratio of 1.5:1 is recommended to avoid internal stresses.Color Masterbatches: EVA, preferable, and PE based color masterbatches including black, up to a maximum of 1%, have no detrimental effect on the properties. It is recommended that all masterbatches should be thoroughly dried before use for 8 hours at 60°C or 4 hours at 80°C in a de-humidifying drier.

Packaging & Availability

- Packaging

The following possibilities are available:

- Moisture resistant sacks containing 25kg

- Boxes with a moisture resistant heat sealed liner containing 600kg

Storage & Handling

- Storage & Shelf Life

TP837B has an unlimited shelf life. However, the following precautions are recommended:

- Packaging should remain sealed

- Avoid storage outside and in direct sunlight.