- Functions:Surface Modifier, Crosslinking Agent, Compatibilizer, Coupling Agent, Moisture Scavenger, Adhesion Promoter

- Chemical Family:Silanes

- Labeling Claims:Low VOC

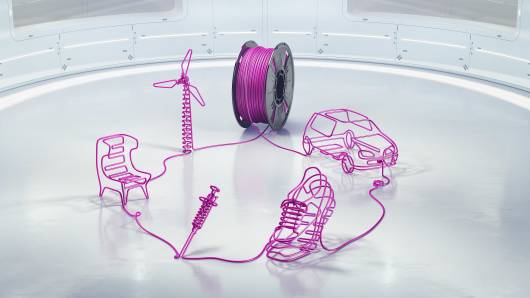

- Compatible Polymers & Resins:High-Density Polyethylene (HDPE), Ethylene Propylene Diene Monomer (EPDM), Ethylene Vinyl Acetate (EVA), Polyethylenes (PE)

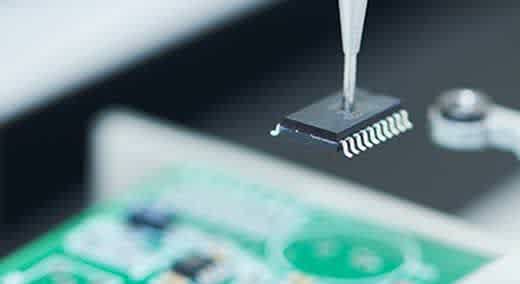

Dynasylan® 6598 is an oligomeric siloxane featuring vinyl, propyl, and ethoxy groups. Developed from Dynasylan® VTMOEO, this colorless and nearly odorless liquid brings enhanced properties. Acting as an excellent silane compatibilizer, it bridges inorganic fillers like kaolin, MDH, and ATH with organic polymers such as EPDM, EVA, and PE. In mineral-filled and peroxide-crosslinked cable systems, Dynasylan® 6598 improves mechanical and electrical attributes, especially in moist conditions. With its high boiling start and flash point, it ensures safety, handling ease, and processing advantages. Furthermore, this product emits significantly less hydrolysis ethanol (VOC) compared to monomeric silanes, addressing environmental considerations.