Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Characteristics

- Moderate OH functionality

- Excellent weatherability and water resistance, excellent chemical resistance

- Good adhesion to primers, fiberglass, plastics, and composites

- Wide range of gloss possible

- Curable at both ambient and elevated temperatures

- Suitable for shop and field applied coatings

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Coating Type

Properties

- Physical Form

- Appearance

- Clear liquid

- Typical Physical Properties

- Coating Properties

- Note

Coating Properties of Fluorourethane

- Cure Conditions: 50°C for 10 min., 160°C for 30 min.

- Substrate: Aluminum panels, 8 mm, acid chromated

| Value | Units | Test Method / Conditions | |

| OH Number (Polymer) | 57 | mg KOH/g | — |

| Solids | 0.5 | wt. % | — |

| Specific Gravity (at 25°C) | 1.08 | — | — |

| Viscosity | 9 | Stokes | — |

| Value | Units | Test Method / Conditions | |

| Blistering | No blistering | — | ASTM D 714 / ISO 4628 |

| Cross Cut Adhesion (Wet/dry) | 5B/5B | — | ASTM D 3359 |

| Flexibility (Cupping test) | min. 7 (cracking) | mm | ISO 1520 |

| Flexibility (Mandrel bend) | 2T (Paint Fracture) | — | ASTM D 4145 |

| Gloss (at 20°) | 51 | — | ISO 2813 |

| Gloss (at 60°) | 78 | — | ISO 2813 |

| Impact Resistance (at Diameter=0.5",Extrusion 0.5 kg) | min. 0.5 | m | ASTM D 2794 |

| Impact Resistance (at Diameter=0.5",Intrusion 0.5 kg) | min. 0.5 | m | ASTM D 2794 |

| Pencil Hardness (Gouge) | 4 | H | ASTM D3363 |

Technical Details & Test Data

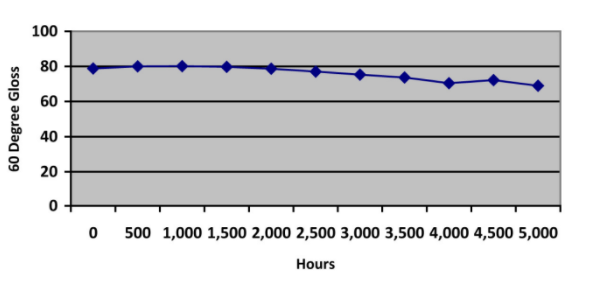

- Accelerated Weathering of LUMIFLON LF-600X: QUV-B Test

UV / Condensation Cabinet Cycle: 8 hours UV at 70° C and 4 hours Condensation at 50° C