Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Material Features

- Impact resistance

- Wear resistance

- Flexibility

- Electrical performance

- Dimensional stability

- Chemical resistance

Applications & Uses

- Applications

- Plastics & Elastomers Processing Methods

- Applications

Extruded moldings

- Film for electrical insulation

- Wire and cable

- Tube

Injection moldings

- Gear member

- Bearing retainer

- Casing

- Case body

Gaskets Cutting and processing

- Plate / Sheet

- Round / Cylindrical bar

Properties

- Typical Properties

- Chemical Resistance

Modified PEEK shows similar or better chemical resistance to PEEK

Fluid

Immersion Condition

Tensile Strength Retention (%)

Elongation Retention (%)

PEEK

KB-1120

KB-1130

PEEK

KB-1120

KB-1130

IRM-903

150 °C

3 Weeks

88

96

104

32

76

54

Diesel No. 2

150 °C

3 Weeks

92

101

106

21

33

94

Steam

260 °C

3 Weeks

97

106

112

36

54

108

| Value | Units | Test Method / Conditions | |

| Flexural Modulus (at 23°C) | 3 | GPa | ASTM D790 |

| Flexural Strength (at 23 °C, 5% Strain) | 109 | MPa | ASTM D790 |

| Impact Strength (at -40 °C) | 79 | J/m | ASTM D256 |

| Impact Strength (at 23 °C) | 208 | J/m | ASTM D256 |

| MIT Flex Life | 796 | Cycles | JIS P8115 |

| Tensile Elongation (at 23°C) | 74 | % | ASTM D638 |

| Tensile Strength (at 23 °C) | 74 | MPa | ASTM D638 |

| Tensile Strength (at 23 °C) | 67 | MPa | ASTM D638 |

Technical Details & Test Data

- Processing

Fluon+ mPEEK can be processed via conventional PEEK molding techniques

- Extrusion molding

- Injection molding

- Pressure molding

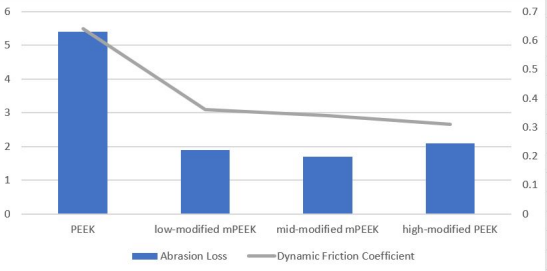

- Wear Property Data

Loss of material during abrasion testing significantly reduced with the addition of fluoropolymer modification

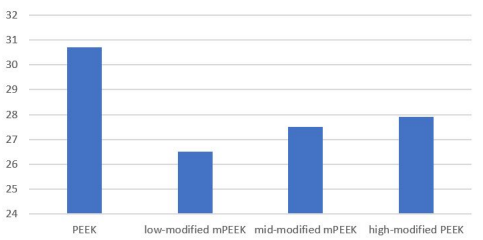

Critical Surface Energy

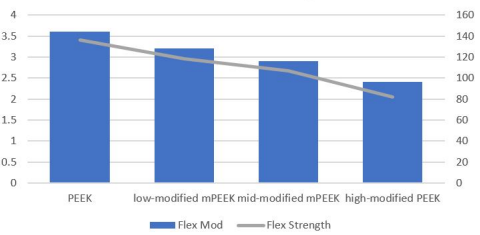

- Flexural Property Data

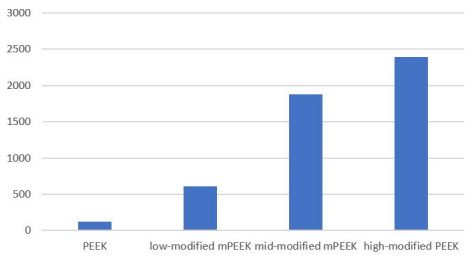

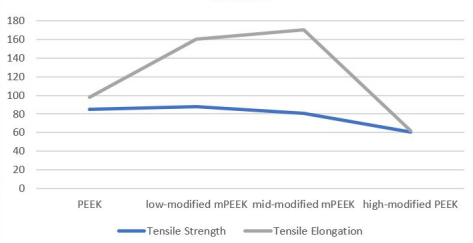

Flex resistance via MIT increased with fluoropolymer modification

Fluxural Modulus & Sterngth

MIT Flex

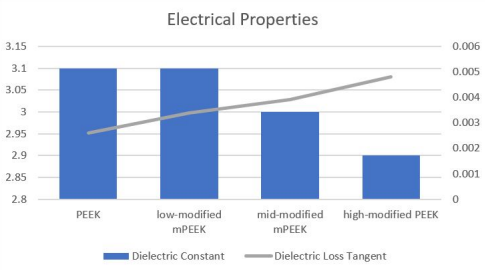

- Electrical Properties

Tensile Properties

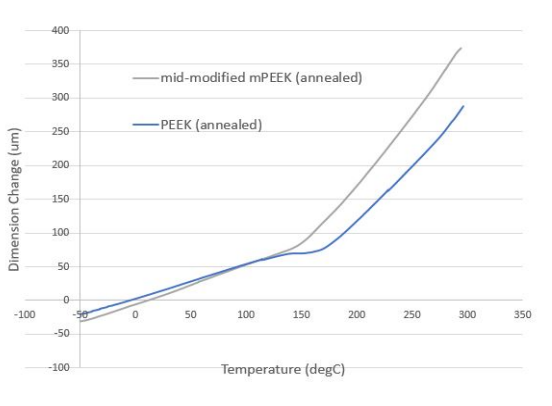

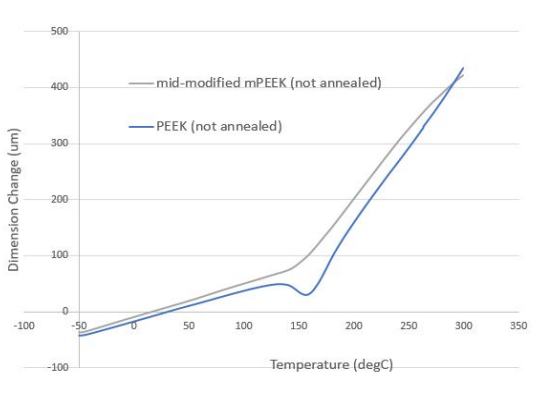

- Coefficient of Thermal Expansion

Dimensional stability across the operatig temperature improved with fluoropolymer modification

Safety & Health

- Safe Handling Information

A summary of the hazards, as defined by OSHA Hazard Communication Standard, 29 CFR 1910.1200 for this product are: Physical hazards: None

Health hazards: None

FOR ADDITIONAL INFORMATION AND HANDLING INSTRUCTIONS READ AGC CHEMICALS AMERICAS, INC. MATERIAL SAFETY DATA SHEET.

Storage & Handling

- Storage and Handling

Heating Fluon® products in excess of 750°F (399°C) can produce toxic fumes. It is, therefore, necessary to provide local exhaust ventilation in areas where Fluon® products are exposed to high temperatures. Avoid breathing fumes or contaminating smoking tobacco with fumes, powder, or dust.

Thermal decomposition of this product will generate hydrogen fluoride, which is corrosive. Corrosion resistance materials are required for prolonged contact with molten resin. Fluon+ mPLASTICS products should be stored in their original containers. This will be either in re-sealable plastic pails, or in drums with the liner bags and chime rings securely re-fastened. Products should be stored indoors at nominal conditions of 23 C and 50% relative humidity. Products should be dried prior to use.