Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Features of EA-2000

- Heat resistance to 260C and superior chemical resistance, equivalent to conventional PFA materials

- Adhesion to other polymers and metals without the use of surface treatment or a separate adhesive layer via a traditional melt-processable method.

- Excellent non-stick properties, low frictional properties, and water and oil repellency (high contact angle)

- Low dielectric constant (2.1) and low dissipation factor (0.001)

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Assumed Applications of EA-2000

- Printed circuit boards (rigid or flexible)

- Heat-resistant insulating tape

- Heat-resistant laminated tubing

- Interposers

- Steel plate laminates

- Ideal for PCB materials

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Coefficient of Water Absorption | max. 0.03 | % | ASTM D570 |

| Dielectric Constant (at 1GHz) | 2.1 | — | ASTM D150 |

| Dielectric Dissipation Factor (at 1GHz) | max. 0.002 | — | ASTM D150 |

| Durometer Hardness | 59 | — | Shore D |

| Elongation (at Break) | 460 | % | ASTM D638 |

| Flexural Modulus | 640 | MPa | ASTM D790 |

| Izod Impact Strength (at 23ºC,Notched) | Non-Break | J/m | ASTM D256 |

| Melting Point | 300 | °C | DSC |

| MFR | 10 – 25 | g/10 min | ASTM D3307 (327°C,49 N) |

| MIT Folding Endurance | 8.0 x 10³ | Cycles | ASTM D2176 |

| Specific Gravity | 2.1 | — | ASTM D792 |

| Specific Heat | 1.05 | kJ/(kg•K) | — |

| Strength (at Break) | 36 | MPa | ASTM D638 |

| Volume Resistance | 6.5 x 10¹⁷ | Ω-cm | ASTM D257 |

Technical Details & Test Data

- Example of Film Extrusion Conditions of EA-2000

An example of the processing conditions for a mono-layer film with EA-2000 is shown below.

Conditions Extruder temperature Roll temperature C1 C2 C3 C4 H D Nip roll temperature EA-2000 300°C 320°C 340°C 340°C 340°C 340°C 180°C Extruder: Ø30 mm single screw (L/D=24)

Die: T-die (450 mm in width)

Line speed: 10 m/minExample of Molding Conditions of EA-2000/Copper Foil Laminate

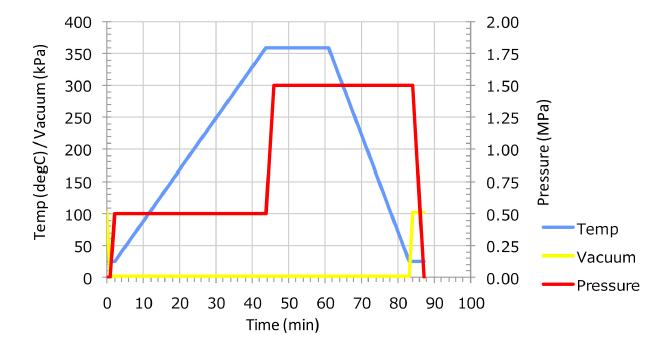

An example of the processing conditions for copper foil laminate with EA-2000 is shown below.

- Film: EA-2000 (30 μm-t)

- Metal Laminate: Copper foil

- Laminate conditions: An adhesion sample (350 mm) is produced using a vacuum press.

- Peel strength measurement method: 90° peel test using 1 cm wide strips.

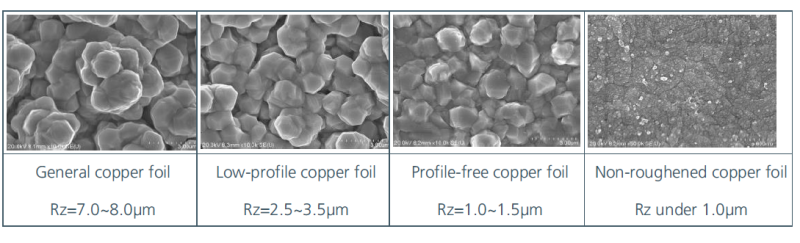

Cu surface roughness Peel strength

(N/cm)Rz (μm) Ra (μm) EA-2000/General copper foil 7.2 1.45 13 EA-2000/Low-profile copper foil 3.0 0.25 11 EA-2000/Profile-free copper foil 1.2 0.19 12 EA-2000/Non-roughened copper foil 0.9 0.13 12

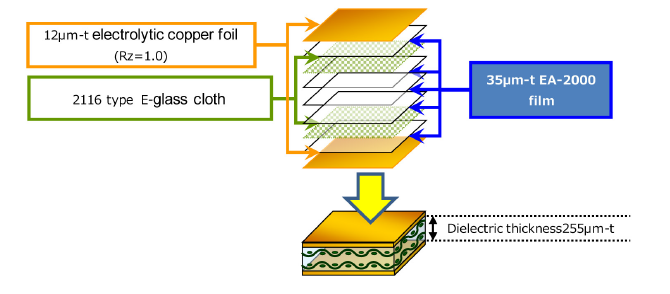

Example Molding Conditions of EA-2000/Glass Cloth

EA-2000/glass cloth substrate molding conditions

- Film: EA-2000 (35 μm-t)

- Copper foil: Electrolytic copper foil roughened surface Rz=1.2 μm (12 μmt)

- Glass cloth: 2116 type E-glass cloth

- Laminate conditions: A substrate sample (350 mm) will be produced with the same conditions using a vacuum press.

Material composition

Characteristics of EA-2000/glass cloth substrate

Characteristics of EA-2000/glass cloth substrate- Favorable relative dielectric constant and dielectric dissipation factor

- Excellent copper foil adhesion and copper plating coverage inside through -holes

- Favorable solder heat resistance with low linear expansion coefficient in the xy-plane

- Technical information

The information and data stated in this material (and any information and data provided to customers) are based on actual data obtained from reliable sources and should not be considered as guaranteed values for matters not stated in this material. We hereby disclaim any warranties, whether express or implied, regarding this material. The user is responsible for complying with all relevant laws and regulations irrespective of whether stated in this material or not. The provision of this material does not grant a license to any patents, trademarks, or licenses for those products, or any licenses to other intellectual properties.

Storage & Handling

- Handling Precautions

All Fluon+ grades should be stored in clean and dry conditions. No special pre-heating or conditioning is required.

As with most fluoropolymers, care is needed when heating EA-2000 pellets and local exhaust ventilation is required. Please refer

to our Safety data sheets (SDS) for guidance.Thermal decomposition of this product will generate hydrogen fluoride, which is corrosive. Corrosion resistant materials are

required for prolonged contact with molten resin.EA-2000 should be processed at a maximum temperature of 380C in order to preserve the adhesive functionality of the polymer