Knowde Enhanced TDS

Identification & Functionality

- Base Oil Type

- Product Type

- Technologies

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Performance Benefits

- Increased lubrication verses other synthetic fluids

- Rejects tramp oils for easy skimming

- Biostable formula extends fluid life

- Low foaming in all water conditions

- Excellent lubrication allowing for moderate machining

- Excellent corrosion protection protects parts, machines and tools

- Settles chips quickly for a clean work environment

Applications & Uses

- Applications

- Application Area

- Recommended Applications & Dilutions

- Recommended for machining and grinding ferrous metals.

- Grinding : 4% to 5%

- Machining : 5% to 8%

Properties

- Color

- Appearance

- Clear green (of Dilution), Clear green liquid (Concentrate)

- Characteristics

| Value | Units | Test Method / Conditions | |

| pH (of 5% Dilution) | 9.0 - 9.7 | — | — |

| Density (at 15°C) | 8.6 | lbs/gal | — |

| Chlorine | No | — | — |

| Nitrites | No | — | — |

| Phenols | No | — | — |

Technical Details & Test Data

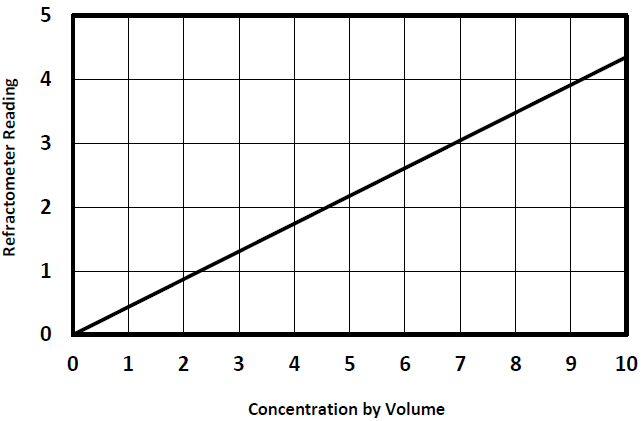

- Concentration Control

Refractive Index Multiplier : 2.3 Refractometer

Reading% Concentration 2 4.6 3 6.9 4 9.2 5 11.5