Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Ink & Toner Type

- Applications

Neutralization of DeCAL 4201 can be achieved using any suitable alkali or volatile amine. These include Ammonia, Monoethanolamine(MEA), Diethanolamine (DMAE), Aminomethyl propanol(AMP) or Triethanolamine(TEA).

DeCAL 4201 tends to swell considerably in the early stages of neutralization. As a result it is recommended that the product be prediluted to with water prior to any neutralization and then left to stabilize for several hours afterwards before use. For full solublisation of the polymer the pH must remain above pH 7 where it exhibits excellent pH/viscosity stability.

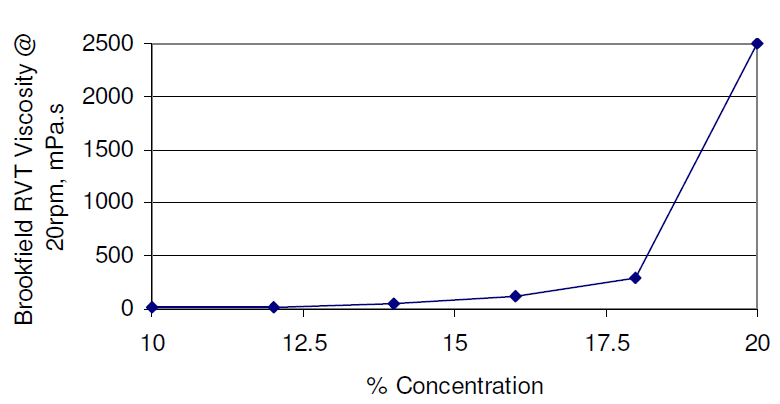

- Concentration vs Viscosity for DeCAL 4201 (20% solids, with MEA)

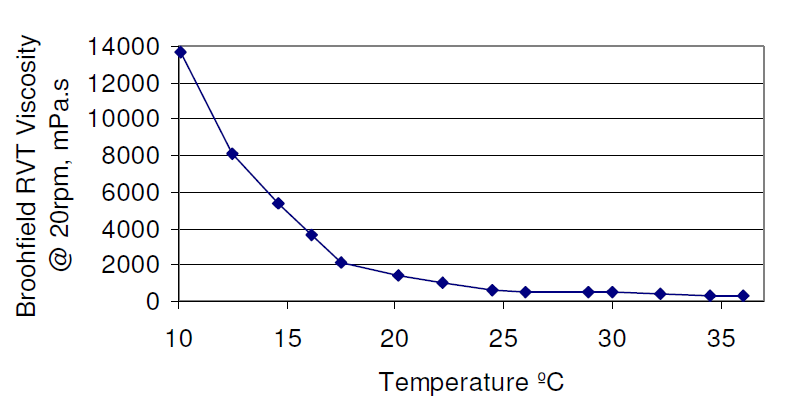

- Temperature vs Viscosity for DeCAL 4201 (20% solids, with MEA)

- Compatibility

DeCAL 4201 is widely compatible with other acrylic, stireneacrylic, PVA, polyesters and shellac resins. Both will tolerate various water soluble solvents such as glycol ethers alcohols and low boiling point esters and ketones, and general pigment compatibility is very good with excellent pigment wetting and color development being achievable.

- Other Uses

- DeCAL 4201 is also suited for use as binders and modifiers for other systems such as waterbased paints and coatings for use in the art and craft, and paper coatings industries.

- Improvements in water and solvent resistance can be achieved via crosslinking through the free carboxyl groups in the polymers. Typical crosslinkers include Zirconium compounds, UF and MF resins and carbodiimides.

Properties

- Physical Form

- Appearance

- White liquid (emulsion)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH | 3.5 | — | — |

| Solid Content | 60.0 | % | — |

| Viscosity (at 25°C, 20 rpm) | 500.0 | mPa.s | Brookfield RVT |

| Density (at 25°C) | 1.1 | g/cm³ | — |

| Acid Value (as 100%) | 77.0 | % | — |

| Initial Softening Point | 100.0 | °C | — |

| Glass Transition Temperature | 35.0 | ºC | — |

Packaging & Availability

- Regional Availability