Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Performance Benefits

- Provides superior die life and surface finish to the workpiece

- Provides superior corrosion protection on all metals

- Non-chlorinated and odorless

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Recommended Applications & Dilutions

Vuldra 516 can be used neat or diluted with water. Dilutions range from 10% to 50%. For a heavier bodied film, add water to product in small quantities while agitating until a smooth cream is obtained. Water can then be added more rapidly until final dilution is reached. For a lighter film, add product to water while agitating until a stable emulsion is formed. Vuldra 516 may be applied by roller coat, swab, spray, dip or recirculation.

Properties

- Color

- Physical Form

- Appearance

- Clear amber liquid (Concentrate)

- Characteristics

| Value | Units | Test Method / Conditions | |

| pH (of 5% Dilution) | 8.2 | - | - |

| Density (at 15°C) | 8.0 | lbs/gal | - |

| Chlorine | No | - | - |

| Sulfur | No | - | - |

| Active Sulfur | No | - | - |

| Phosphorous | Yes | - | - |

Technical Details & Test Data

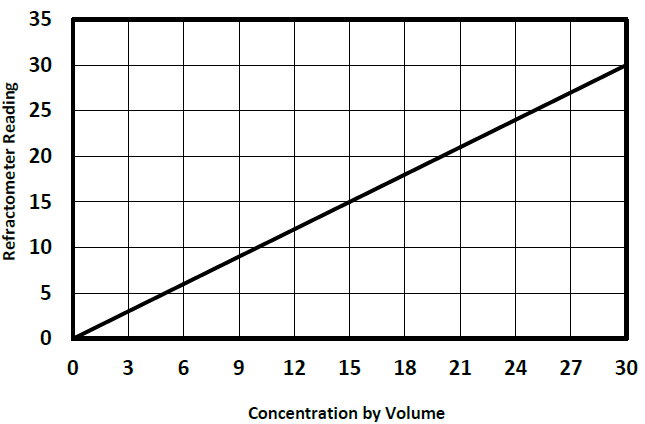

- Concentration Control

Refractive Index Multiplier : 1

Refractometer Reading % Concentration

10 10 15 15 20 20 25 25