Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Pigment Type

- CASE Ingredients Functions

- Technologies

- Product Families

- Chemical Description

Calcium Phosphate Based Inhibitor

- Mechanism

- Cathodic passivation and ion exchange/scavenging

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Benefits

The jet-milled feature of HALOX® 430 JM offers significant advantages :

- Thin film applications (<10 microns)

- Easier to disperse

- Cleaner grinds

- Improved efficiency

- The Sustainable Future

- Patented Calcium Phosphate

- Ion Exchange Technology

- JM (jet milled version) for smaller particle size

- Advantages

- The jet-milled feature offers significant advantages for thin film applications (<10 microns). It is easy to disperse and provides cleaner grinds for improved corrosion inhibition efficiency. It is a moderate solubility corrosion inhibitor and hexavalent chromate replacement option for galvanized, Galvalume™, and aluminum alloys.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Applications

- Thin Film Coatings

- WB 2K Epoxies

- SB 2K Epoxies

- Hybrids

- High Solids Epoxies

- Aerospace, Auto Refinish

- Cathodic Inhibitor

- Clear Coats

- Latex Emulsions

- WB 2K Polyurethane

- DTM Finishes

- Polyesters

- Powder Coatings

- Recommended Loading Levels

Application recommended loading levels based on total formula weight.

Coatings System Water-borne Solvent-borne 2K Epoxy 2-6% 8-12% Alkyds & Modified Alkyds 2-6% 6-10% 2K Polyurethane 2-6% 6-10% Acrylic Copolymer 2-5% - Polyester Melamine/TGIC - 6-9%

Properties

- Appearance

- White Powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 2.7 | g/ml | — |

| Hegman Grind | min. 6 | — | — |

| Mean Particle Size | 2 | microns | — |

| Moisture Content | 1.1 | % | — |

| Oil Absorption | 50 | lbs/100 lbs | — |

| pH (10% Solution by Weight) | 8 | — | — |

| Solubility in Water | 0.02 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

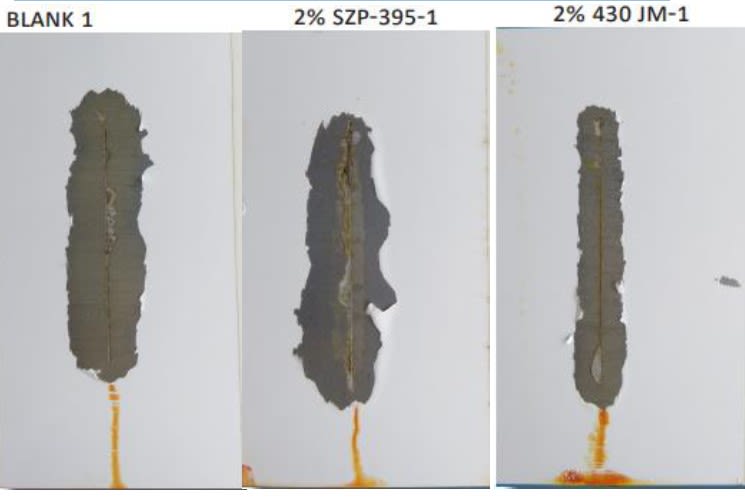

- HALOX® 430 JM versus Zinc Containing Cl, SZP 395

Water based Light Industrial PU DTM with 2% CI on TFW

Panel Data

B1000 Gloss Scribe Creep ASTM D

1654ID Cross

Hatch

Adhesion20° 60° 85° Scribe Creep

(mm)

AVG of 2

panelsB1000

% Improvement

vs CTLAVG of 2 panels Blank 3B 37.4 76.2 96.4 10 CTL 2% SZP395 3B 29.5 72.6 95.6 11.75 85% 2% 430 4B 28.2 71.4 96.7 5.5 182% ASTM B117, 144 hours, DFT @50 microns, B1000

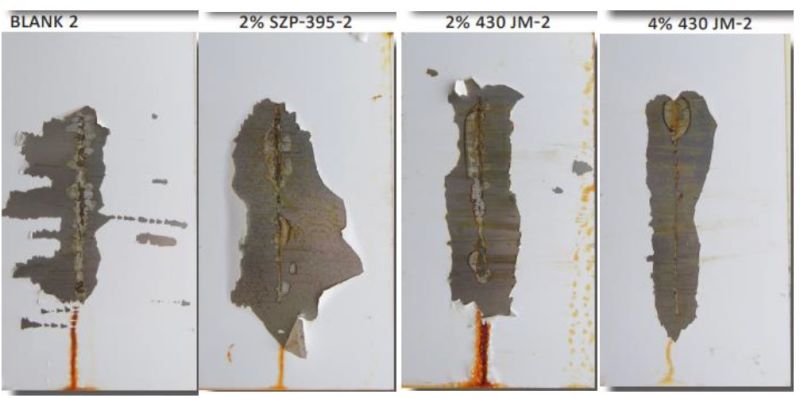

Water based Light Industrial PU DTM with 2 4% CI on TFW

Panel Data

CRS Gloss 144 hours ID Cross

Hatch

Adhesion20° 60° 85° Scribe Creep

(mm)

AVG of 2

panels%

Improvement

vs CTLAVG of 2 panels Blank 0B 39 76 95.7 19.75 -- 2% 395 0B 30.3 72.3 97 19 104% 2%

430JM2B 27.9 70.2 96.4 11.5 172% 4%

430JM2B 22 66.7 95.3 9.875 200% ASTM B117, 144 hours, DFT @50 microns, CRS

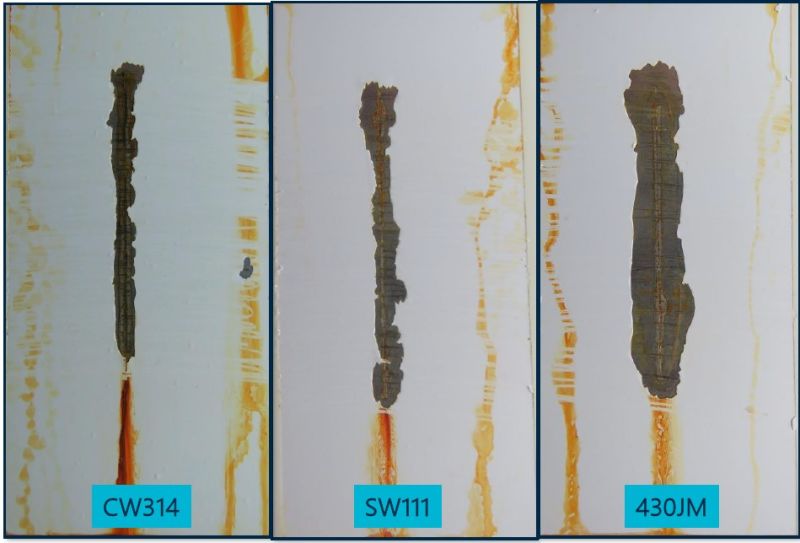

- Heavy Metal Free versus Zinc

Water based Light Industrial DTM Epoxy, ASTM B117, 4 mils DFT over CRS

CRS 168 Hours Sample Panel # DFT Visual

Scribe

Creep

Rating

ASTM

D 1654Field

Corrosion

ASTM

D

610Field

Blistering

ASTM D

714Scribe Creep

(mm) AVG of

2 panels%

Improvement

vs CTLCW314 1 4.72 8 10 10 2.875 917% 2 4.70 8 10 10 SZP395 1 4.56 8 10 10 3.9375 670% 2 4.55 6 10 10 700 1 4.59 5 10 10 670% 414% 2 4.7 4 10 10 5% loading level

- Factors to Consider while Creating Coatings Solutions

- Combine the inhibitors utilize synergy of multiple mechanisms to achieve desired performance.

- Inorganic/Flash Rust

- Inorganic/Inorganic

- Inorganic/Organic

- Optimize Solubility of the inhibitor. Synergize short term and long term corrosion inhibitors based on their solubility.

- Inhibitor Concentration avoid direct weight to weight replacements. Beneficial to optimize usage level.

- Substrate specific corrosion inhibitor selection can be substrate dependent.

- Combine the inhibitors utilize synergy of multiple mechanisms to achieve desired performance.

Storage & Handling

- Shelf Life

- 36 Months