Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- CASE Ingredients Functions

- CAS No.

- 2530-83-8

- EC No.

- 219-784-2

- Technologies

- Product Families

- Mechanism

- Hydrophobic film formation, adhesion promoter, synergist

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- The Sustainable Future

Sol Gel Technology

- Features

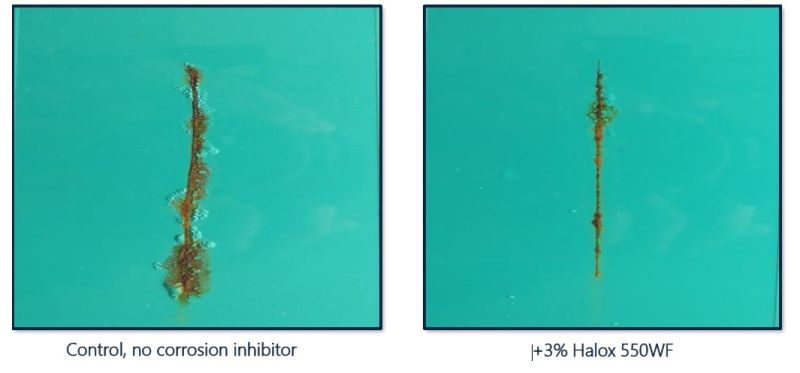

- HALOX® Specialty Inhibitors provide formulators with additional tools to increase hydrophobicity and adhesion in challenging environments. The performance attributes of HALOX® 550 WF lead to overall improvements to barrier properties through both the formation of domains within the pores of a coating in addition to an affinity for bonding at the metal surface.

- As defined by TSCA, these composite pigments are classified as mixtures. All components of these mixtures are listed in the TSCA Chemical Substances Inventory.

- Advantages

- HALOX® 550 WF is a liquid, can be post-added, maintains high gloss and improves adhesion.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Use Level

- 0.5 - 3.0 %

- Recommended Loading Levels

Recommended loading level is 0.5-3.0% based on total formula weight. This product will not provide anti-flash rust protection

- Applications

- Gloss Coatings

- Clear Coats

- Thin Films (<1.0 mil)

- Anti-fingerprint protection

- Synergist to jet-milled products

- Solvent Based Coatings (e.g. Polyurethanes)

- Strontium chromate and chromic acid replacement

- Water Based Coatings (e.g. WR Alkyds)

- All metal primers

- Water-based and solvent-based topcoats, powder coating resins and temporary clear coatings.

- It is an adhesion promoter for galvanized steel, pretreatment chemistries, acidic systems (pH 3-6) and thin-film coatings (<10 µm).

Properties

- Appearance

- Clear colorless liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Specific Density | 0.99 | — | — |

| VOC (EPA Meth 24) | 979 | g/L | — |

| VOC (EPA Meth 24) | 8.17 | lbs/gal | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Silane Based Corrosion Inhibitor

Light Industrial Water Reducible Alkyd

ASTM B-117 @ 96 hours 2 mils DFT over CRS

Gloss Control 3% 550WF 60° 79 91 85° 90.5 97.1

- Factors to Consider while Creating Coatings Solutions

- Combine the inhibitors utilize synergy of multiple mechanisms to achieve desired performance.

- Inorganic/Flash Rust

- Inorganic/Inorganic

- Inorganic/Organic

- Optimize Solubility of the inhibitor. Synergize short term and long term corrosion inhibitors based on their solubility.

- Inhibitor Concentration avoid direct weight to weight replacements. Beneficial to optimize usage level.

- Substrate specific corrosion inhibitor selection can be substrate dependent.

- Combine the inhibitors utilize synergy of multiple mechanisms to achieve desired performance.

Storage & Handling

- Shelf Life

- 12 Months