Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- CAS No.

- 171054-89-0

- EC No.

- 419-240-6

- Technologies

- Product Families

- Chemical Description

Organic Acid Amine Complex

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Features

HALOX® Organic Corrosion Inhibitors are effective against flash rusting and in-can corrosion prevention, though the benefits of using these products does not end there. Our HALOX® Organic Corrosion Inhibitors are ideally suited for high gloss, thin film, and clear coat applications. They also provide superior synergy when used in combination with inorganic corrosion inhibitors in traditional coatings. To achieve desired performance of your resin system proper selection of HALOX® Inhibitors in essential.

- Advantages

- HALOX® 570 is a powder. It is a dual flash rust and corrosion inhibitor.

- Developed for weld seams it provides both flash and galvanic rust inhibition

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Use Level

- 1 - 4 %

- Recommended Loading Levels

- Recommended concentrations range from 1-4% HALOX® 570 (30% solution) based on total formula solids.

- The amount of HALOX® 570 required for optimum performance should be determined in trials over the recommended concentration range.

- Applications

- Co-Polymers

- Styrene/Acrylic Latexes

- Acrylated Epoxy Esters

- 2K Epoxies

- Alkyds

- Alkyd/Acrylic Blends

- 1K and 2K Polyurethanes

- DTM Primerless Topcoats

- Some Solvent Based Systems

- Water Based Acrylic Latexes

- Water Systems

- Can Eliminate Flash Rust

- Effective on Weld Seams

- UV Cured Coatings

- Concrete admixtures

- Effective over weld seam flash rusting.

- Used in both waterborne primers and direct-to-metal topcoats.

- In direct-to-metal coatings, HALOX® 570 has minimal effect on gloss reduction.

Properties

- Appearance

- White to light beige crystalline powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.24 | g/ml | — |

| Melting Range | 67 - 73 | °C | — |

| Oil Absorption | 12.9 | lbs/100 lbs | — |

| pH (10% Solution by Weight) | 6.5 | — | — |

| Solubility in Aliphatic Hydrocarbons (Boiling Range : 160-200°C) (at 20°C, in neutralized 30% solution) | max. 1 | g/100g | — |

| Solubility in Diethylene glycol methyl ether (at 20°C, in neutralized 30% solution) | approx. 40 | g/100g | — |

| Solubility in Isopropanol (at 20°C, in neutralized 30% solution) | approx. 30 | g/100g | — |

| Solubility in Methyl-isobutylketone (at 20°C, in neutralized 30% solution) | approx. 15 | g/100g | — |

| Solubility in n-Butanol (at 20°C, in neutralized 30% solution) | approx. 20 | g/100g | — |

| Solubility in Water (at 20°C, pH 7, in neutralized 30% solution) | max. 0.25 | g/100g | — |

| Solubility in Xylene (at 20°C, in neutralized 30% solution) | max. 1 | g/100g | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Incorporation

There are several methods of incorporating HALOX® 570. The preferred method is to make a pre-neutralized concentrate in water using an amine that is volatile under your curing conditions, then post-add or add to the letdown.

A neutralization example:HALOX® 570 (30% solution) Weight De-ionized Water 62.8 28% Ammonium Hydroxide 7.2 HALOX® 570 30.0 Total 100.0 - Stir slowly, adjust pH 8-9

- Alternatively, a concentrate can be made in a co-solvent according to the solubility data above, then post-add or add to the letdown. It may also be added to a pigment grind as a solid.

- In general, add the aqueous concentrate or co-solvent solution to the amine/amide part of a 2 pack epoxy or to the polyol of a 2 pack polyurethane.

- If possible, avoid systems with acetic acid-use surfactant stabilized hardeners instead.

- If you are removing a heavy metal based anti-corrosive pigment, compensate for its removal with an extender (filler) so that the ratio PVC:CPVC remains constant. However, HALOX® 570 can be used in conjunction with anti-corrosive pigments, preferably based on compounds defined as non-toxic or reportable under applicable regulations. Check compatibility, shelf life (e.g. accelerated at high temperature), cure and pot-life, if applicable. Other formulation variables may also be optimized, for example, dispersants, surfactants, and PVC:CPVC ratio.

- Factors to Consider while Creating Coatings Solutions

- Combine the inhibitors utilize synergy of multiple mechanisms to achieve desired performance.

- Inorganic/Flash Rust

- Inorganic/Inorganic

- Inorganic/Organic

- Optimize Solubility of the inhibitor. Synergize short term and long term corrosion inhibitors based on their solubility.

- Inhibitor Concentration avoid direct weight to weight replacements. Beneficial to optimize usage level.

- Substrate specific corrosion inhibitor selection can be substrate dependent.

- Combine the inhibitors utilize synergy of multiple mechanisms to achieve desired performance.

- Combining Corrosion Inhibitors

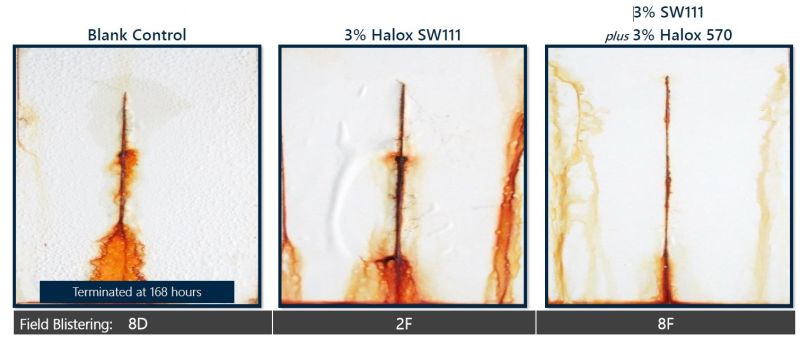

DTM WB Epoxy, ASTM B117 @ 336 hrs, 2 mils DFT over CRS

Storage & Handling

- Shelf Life

- 36 Months