Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

- Chemical Description

Zinc Phosphate Complex

- Mechanism

- Precipitation and anodic passivation

Features & Benefits

- CASE Ingredients Features

- Features

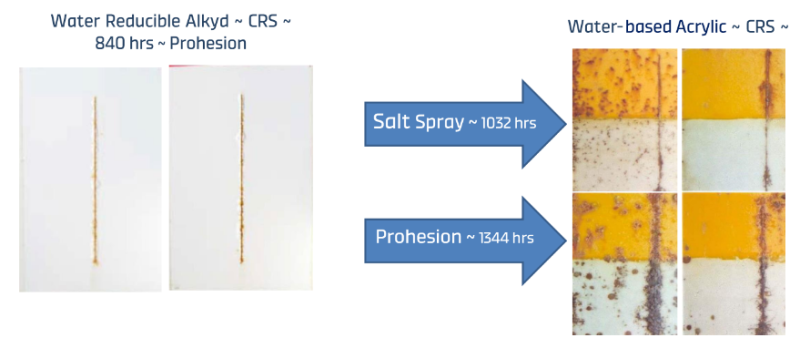

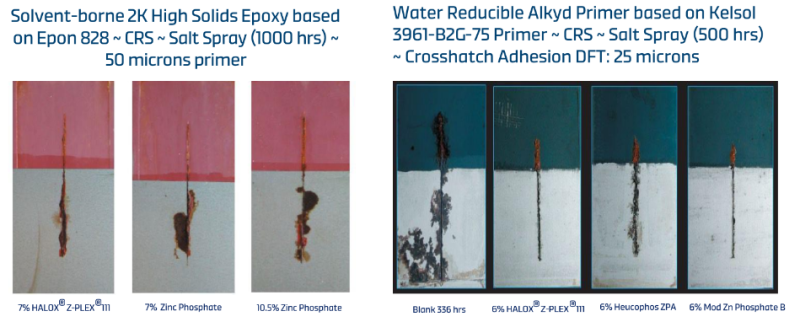

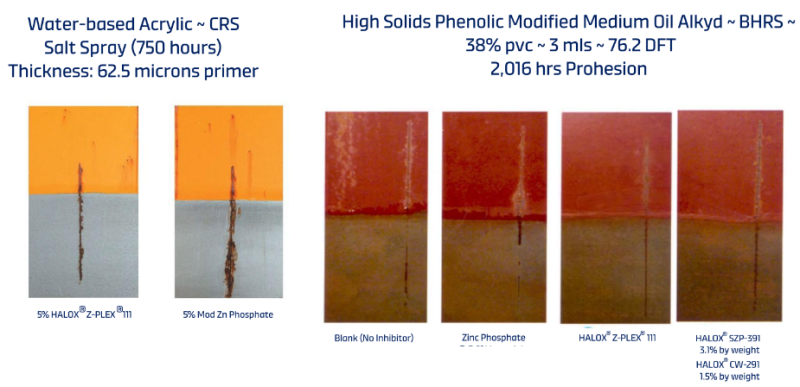

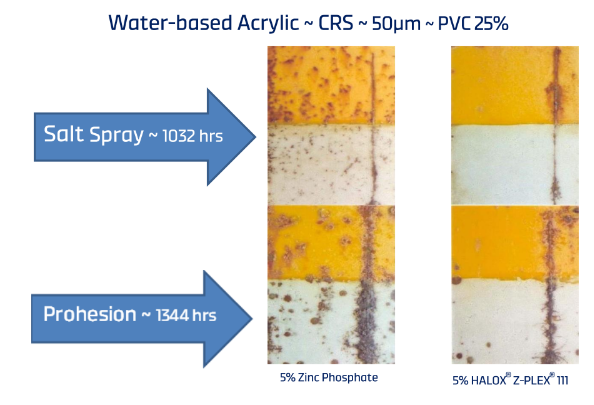

HALOX® Z-PLEX® 111 is specially engineered to contain 80% fewer zinc compounds while providing improved corrosion efficiency. This engineered zinc phosphate complex is designed to compete head-to-head with standard zinc phosphate pigments. For light industrial coatings, the reduced cost brings realized savings to your formulation without sacrificing performance.

HALOX® corrosion inhibitive pigments have provided a high standard of protection without the use of lead or hexavalent chromium compounds. ICL Phosphate Specialty proudly offers a variety of Inorganic Corrosion Inhibitors based on the proven performance of zinc. Our Z-PLEX® products are designed to allow you to choose the right inhibitor for your performance and manufacturing needs.

- Advantages

- HALOX® Z-PLEX 111 is low-cost!

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Applications

- Short Oil Alkyds

- Medium Oil Alkyds

- Long Oil Alkyds

- Solvent 2K Epoxies

- Epoxy Esters

- Latex Emulsions

- Polyesters

- PVDC

- Water Reducible Epoxies

- WR Alkyds

- High Solids Epoxies

- Water Based Epoxy Esters

- Thin Film Applications

- Acrylic Lacquer Emulsions

- Acid Catalyzed Systems

Properties

- Appearance

- White Powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 3 | g/ml | — |

| Hegman Grind | 5 | — | — |

| Mean Particle Size | 5.9 | microns | — |

| Moisture Content | 0.6 | % | — |

| Oil Absorption | 36.3 | lbs/100 lbs | — |

| pH (10% Solution by Weight) | 8.1 | — | — |

| Solubility in Water | 0.02 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Test Data

An ideal zinc phosphate replacement as it contains a low level of zinc compounds (20% wt.) Recommended as a direct weight replacement of zinc phosphate.

Storage & Handling

- Shelf Life

- 36 Months