Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

- Chemical Description

Inorganic/Organic Phosphosilicate

Features & Benefits

- CASE Ingredients Features

- Features

HALOX® corrosion inhibitive pigments have provided a high standard of protection without the use of lead or hexavalent chromium compounds. ICL Phosphate Specialty proudly offers a variety of Inorganic Corrosion Inhibitors based on the proven performance of zinc. Our Z-PLEX® products are designed to allow you to choose the right inhibitor for your performance and manufacturing needs. HALOX® Z-PLEX 750 is an inorganic corrosion inhibitor combining organic and inorganic inhibitor synergies.

- Benefits

- Excellent passivation

- Improved wet adhesion

- Outstanding blister resistance

- Enhanced barrier properties

- Advantages

HALOX® Z-PLEX 750 is value-added: Improves humidity resistance, wet adhesion, pigment dispersion and stability, lower oil absorption, outstanding blister resistance, barrier properties, and anodic passivation.

Applications & Uses

- Markets

- Applications

- Recommended Loading Levels

Recommended loading levels range from 3-7% based on total formulation weight for water and solvent-borne coatings. However, the amount of HALOX® Z-PLEX 750 required for optimum performance should be determined in trials over the recommended concentration range.

- Applications

- Latex Emulsions

- SB 2K Epoxies

- High Solids Epoxies

- Hybrids

- SB Alkyds

- Water Reducible Alkyds (Air Dry)

- Chromate-Replacement

- Water based and solvent based paints: acrylic, alkyd, epoxy, and epoxy esters coatings.

Properties

- Appearance

- White Powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 3 | g/ml | — |

| Mean Particle Size | 5 | microns | — |

| Oil Absorption | 27 | lbs/100 lbs | — |

| pH (10% Solution by Weight) | 7.2 | — | — |

| Solubility in Water | 0.02 | % | — |

| Total Zinc Compounds | 20 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

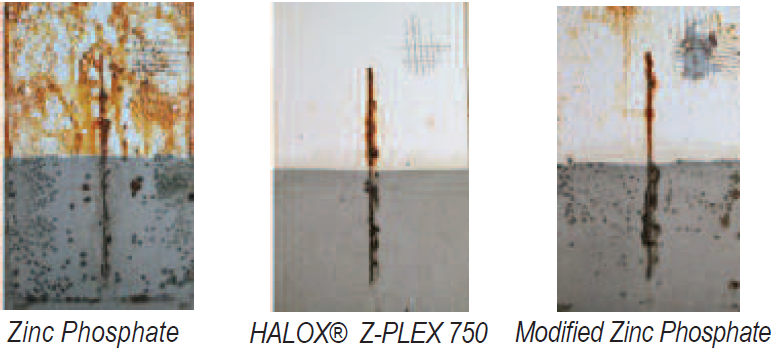

- Cross Hatch Adhesion Test

Water Reducible Acrylic Alkyd after 400 Hours of Salt Spray

(Bonderite 1000 - 2.5 mils (62.5 microns) - 5% TFW)

(Cross hatch adhesion performed immediately after extraction from test cabinet)

Storage & Handling

- Shelf Life

- 36 Months