Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Product Highlights

- Excellent balance of Tg, toughness, modulus, and mechanical properties

- Low moisture absorption and low outgassing

- Qualified for satellite and high-modulus fiber Applicationss

Applications & Uses

- Markets

- Composites Processing Methods

- Recommended Applications

- Space & Satellite

- Dimensionally stable structure

- Processing Method

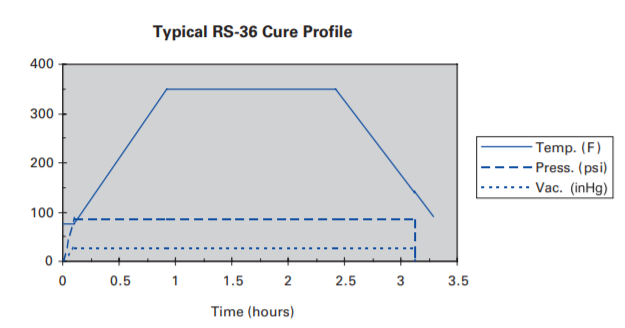

Recommended processing for RS-36 is described below. Special moisture control procedures and bleed bagging materials required for cyanate ester resin systems are not necessary for RS-36

CURE PARAMETERS:

- Apply vacuum and leak check. For autoclave or press cycles apply pressure of 45–85 psi

- Heat to 177°C (350°F) (5°C/+10°F) at 2°C (5°F) per minute ± 3°F/1.5°C per minute

- Hold at 177°C (350°F) for 90 minutes (+15 min/-0 min)

- For autoclave cures at 40–85 psig, vent to atmosphere at 20 psig or maintain dynamic vacuum, depending on structural Applications

- Cool at 5°F/min to below 60°C (140°F). Release vacuum and autoclave pressure

Properties

- Physical Form

- Typical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.24 | g/cc | — |

| Gel time at 177°C (350°F) | 15–25 | minute | ASTM D 3532 |

| Moisture Absorption after 30 days at 82°C (180°F) | 3 | % | — |

| Outgassing (CVCM) | 0.01 | % | ASTM E 595 |

| Outgassing (TML) | 0.4 | % | ASTM E 595 |

| Outgassing (TML-WVR) | 0.12 | % | ASTM E 595 |

| Outgassing (WVR) | 0.17 | % | ASTM E 595 |

| Value | Units | Test Method / Conditions | |

| Dry Tg by RDA (RS-36) | 181 (358) | °C (°F) | — |

| Dry Tg by RDA (RS-36-1) | 190 (374) | °C (°F) | — |

Storage & Handling

- Shelf Life

- Out Life: Up to 30 days at ambient

- Frozen Storage Life: 12 months at -18°C (< 0°F)

Out life is the maximum time allowed at ambient temperature before cure.