Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Product Highlights

- Outstanding compression after impact (CAI)

- Low dielectric constant and loss tangent

- Outstanding hot/wet properties

- Very low moisture absorption

- Long room temperature out life and freezer storage life

- Meets NASA requirements for outgassing

- High performance product offering an excellent balance of electrical, mechanical, and general properties for highly loaded dielectric structures in severe impact environments

Applications & Uses

- Markets

- Composites Processing Methods

- Recommended Applications

- Radome

- High impact and load environment Applicationss

- Low observable structures

- Aircraft and space structures

Properties

- Physical Form

- Thermal Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tg (by DMA) cured at 180°C (356°F) | 189 (372) | °C (°F) | — |

| Value | Units | Test Method / Conditions | |

| Dielectric Constant at 10 GHz | 2.98 | — | — |

| Dielectric Constant at 20 GHz | 2.85 | — | — |

| Dielectric Constant at 30 GHz | 2.85 | — | — |

| Dielectric Constant at 40 GHz | 3.02 | — | — |

| Loss Tangent at 10 GHz | 0.013 | — | — |

| Loss Tangent at 20 GHz | 0.014 | — | — |

| Loss Tangent at 30 GHz | 0.016 | — | — |

| Loss Tangent at 40 GHz | 0.015 | — | — |

| Outgassing (CVCM) | max. 0.01 | % | — |

| Outgassing (TML) | 0.47 | % | — |

| Outgassing (WVR) | 0.29 | — | — |

| Resin Density | 1.21 | g/cc | — |

Technical Details & Test Data

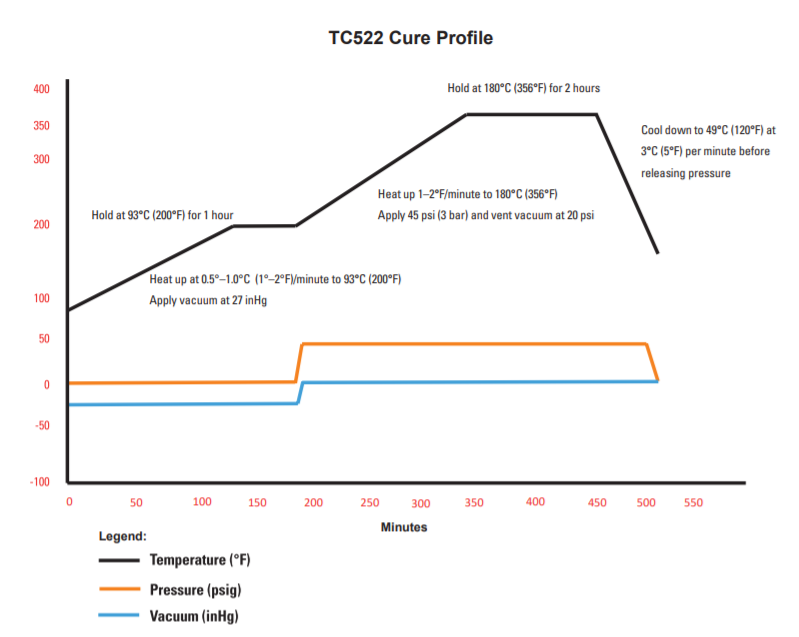

- Recommended Cure Cycle

- After debulking as shown in Figure 2 and assembling the laminate for cure as shown in Figure 3, proceed to cure the laminate as described (see Figure 1)

- Apply vacuum to a level of at least 0.9 bar (27 inHg)

- Ramp temperature at 0.5–1°C (1–2°F) per minute to 93°C (200°F) and hold for 1 hour

- Apply 3 bar (45 psi) and vent vacuum after pressure reaches 1.3 bar (20 psi)

- Ramp at 0.5–1°C (1–2°F) per minute to 180°C (356°F) and hold for 2 hours

- Cool down to 49°C (120°F) at 3°C (5°F) per minute or slower before releasing pressure

Safety & Health

- Environmental Controls

Toray recommends that any composite or adhesive lay-up be performed in a clean area visibly free from dust and other contaminants. Any work surfaces should likewise be free of residue, dust, or debris. No eating or smoking shall be allowed in the shop area. For radome materials, conductive materials shall not be allowed in the process area. The processing shop area should be maintained between 16–25°C (60–77°F) with a relative humidity of no greater than 70%.

Storage & Handling

- Shelf Life

- Out Life: 21 days out life < 21°C (70°F) and < 60% RH

- Frozen Storage Life: 12 months storage life at -18°C (< 0°F) or below

- Product Handling

-

FREEZER STORAGE: Resin prepregs should always be sealed in an airtight bag and kept frozen below -18°C (0°F) when not being used. Best practice is to always keep a bag of activated desiccant (silica moisture absorber) in the core of the prepreg roll should a pinhole rupture develop in the bag or other problem occurs.

- HANDLING OF MATERIALS: When handling any prepreg materials, one should always wear clean, powder-free latex gloves. This will assure that no hand oils are transferred to the prepreg and/or composite during processing. The presence of oils in the part could lead to problems in both mechanical and electrical performance of the part. This also guards against dermatitis that could occur with certain users.

-