Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Pigment Type

- CASE Ingredients Functions

- Technologies

- Product Families

- Mechanism

- Precipitation and anodic passivation

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- The Sustainable Future

- Strontium Phosphosilicate

- Low solubility

- Well suited for epoxy systems

- Advantages

- HALOX® SW-111 performs in most demanding resins where the reactivity of zinc-containing anti-corrosive pigments can be problematic.

- Features

- Designed for long-term high-performance applications

- Surpasses corrosion resistance of zinc-based inhibitors without sacrificing in-can paint stability

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Recommended Loading Levels

Recommended loading levels range from 5-10% based on total formula weight. Synergistic properties have been found [in the areas of corrosion and humidity resistance] when HALOX® SW-111 is used in combination with HALOX® Zinc Phosphate [1:1 ratio] in some water-borne systems.

- Applications

- Water Based Epoxies

- WR Alkyds

- Solvent 2K Epoxies

- Latex Emulsions

- Caulks and Sealants

Properties

- Appearance

- White Powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 2.8 | g/ml | — |

| Hegman Grind | 5 | — | — |

| LOI (at 450°C) | 4 | % | — |

| Mean Particle Size | 5.9 | microns | — |

| Moisture Content | 0.8 | % | — |

| Oil Absorption | 45.1 | lbs/100 lbs | — |

| pH (10% Solution by Weight) | 7.9 | — | — |

| Solubility in Water | 0.03 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

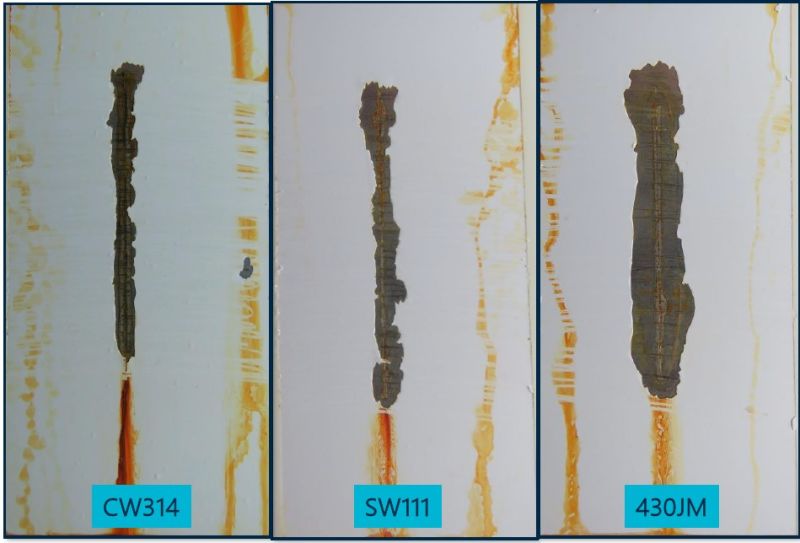

- Heavy Metal Free versus Zinc

Water based Light Industrial DTM Epoxy, ASTM B117, 4 mils DFT over CRS

CRS 168 Hours Sample Panel # DFT Visual

Scribe

Creep

Rating

ASTM

D 1654Field

Corrosion

ASTM

D

610Field

Blistering

ASTM D

714Scribe Creep

(mm) AVG of

2 panels%

Improvement

vs CTLCW314 1 4.72 8 10 10 2.875 917% 2 4.70 8 10 10 SZP395 1 4.56 8 10 10 3.9375 670% 2 4.55 6 10 10 700 1 4.59 5 10 10 670% 414% 2 4.7 4 10 10 5% loading level

- Factors to Consider while Creating Coatings Solutions

- Combine the inhibitors utilize synergy of multiple mechanisms to achieve desired performance.

- Inorganic/Flash Rust

- Inorganic/Inorganic

- Inorganic/Organic

- Optimize Solubility of the inhibitor. Synergize short term and long term corrosion inhibitors based on their solubility.

- Inhibitor Concentration avoid direct weight to weight replacements. Beneficial to optimize usage level.

- Substrate specific corrosion inhibitor selection can be substrate dependent.

- Combine the inhibitors utilize synergy of multiple mechanisms to achieve desired performance.

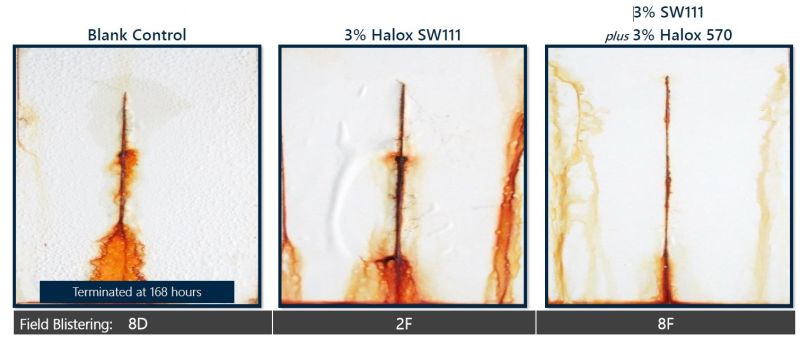

- Combining Corrosion Inhibitors

DTM WB Epoxy, ASTM B117 @ 336 hrs, 2 mils DFT over CRS

Storage & Handling

- Shelf Life

- 36 Months