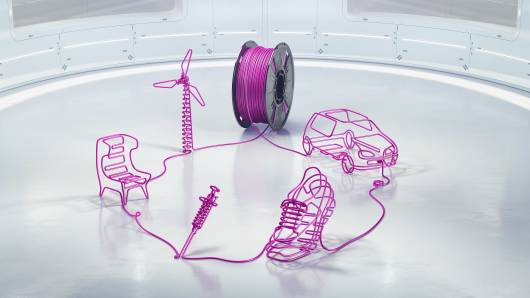

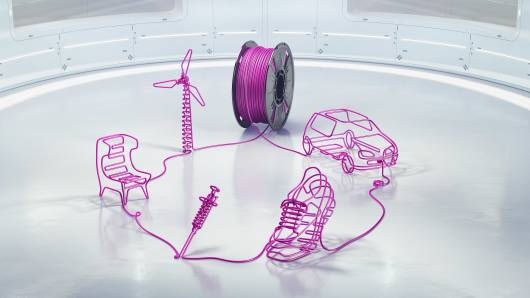

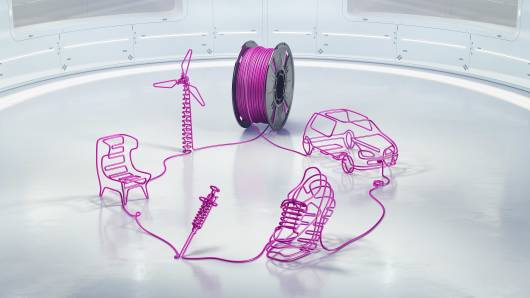

- Functions:Processing Aid, Compatibilizer

- Compatible Polymers & Resins:Polypropylenes (PP), Polyethylenes (PE), Polyolefins, Polyamides, Polyesters

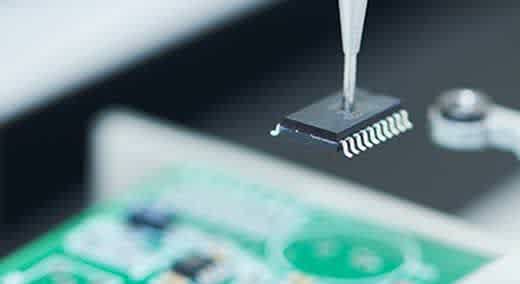

- Processing Methods:Blow Molding, Isostatic Molding

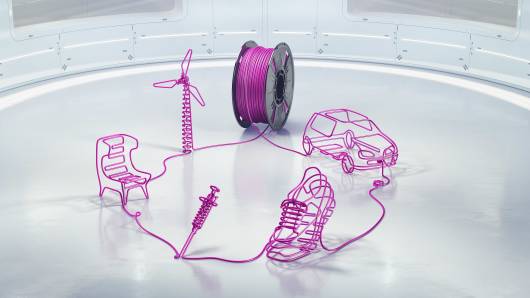

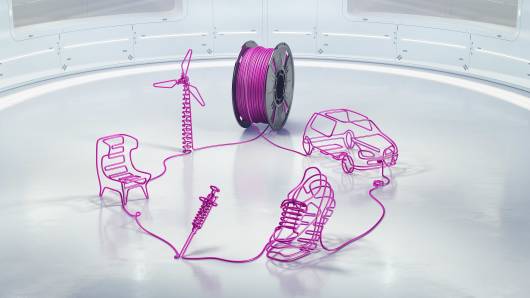

- End Uses:Film, Automotive Applications, Consumer Applications, Strapping, Sheets, Appliances

TEGO® Cycle CP 320 is an organo-modified siloxane that is used as a processing additive, compatibilizer, and for permanent modification of polymer properties. It is particularly suitable for recycled polymers, as it can be used to compatibilize PE in PP, PP in PE, and PA in polyolefins. TEGO® Cycle CP 320 is ideal for producing automotive parts, electronic appliances, packaging materials, consumer goods, and oriented packaging straps. Its use provides several advantages for specific applications, including improved mechanical performance, better weld line strength, and prevention of stress cracking and whitening. It also improves mold release properties, reduces manual interventions, and allows for more exact reproduction of surface structure, resulting in shorter cycle times.