Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- INCI Name

- CASE Ingredients Functions

- Cosmetic Ingredients Functions

- Plastics & Elastomers Functions

- CAS No.

- 112926-00-8

- EC No.

- 601-214-2

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- CASE Ingredients Features

- Materials Features

- Product Features

- Low thickening effect and excellent processability enable high loading levels of polymer systems

- Excellent reinforcing properties in silicone rubber applications at high filler loading levels (e.g. selflevelling RTV-1, RTV-2, LSR)

- Well suited for transparent systems

- Free-flow aid for powders

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Physico-Chemical Properties

Value Units Test Method / Conditions HCL Content max. 0.025 % - TiO₂ Content max. 0.03 % - Fe₂O₃ Content max. 0.01 % - SiO₂ Content min. 99.8 % - Tamped Density* (Modified) approx. 140 g/l ISO 787-11 Specific Surface Area (BET) 135 - 185 m²/g - SiO₂ Content (based on ignited material) min. 99.8 % - pH Value (in 4% dispersion) min. 5 - - Loss on Drying* (at 105 °C, 2 hours) max. 0.5 % - Carbon Content 2.0 - 4.0 % - - Note

* ex plant

- Physico-chemical Properties of Silica Products

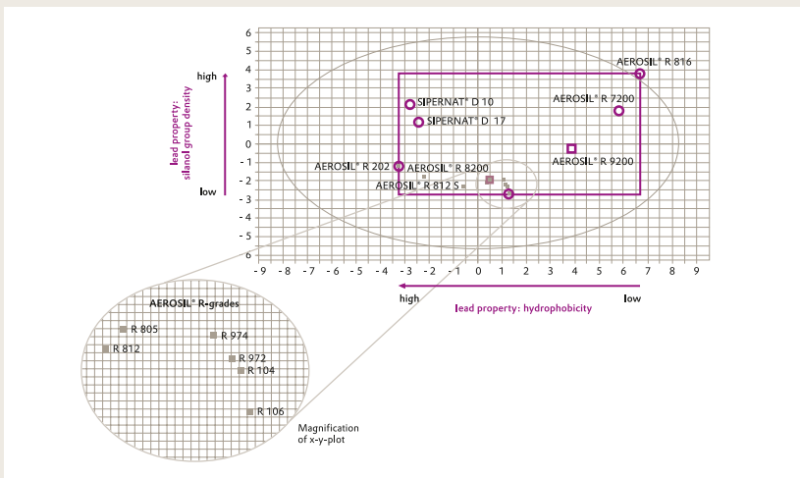

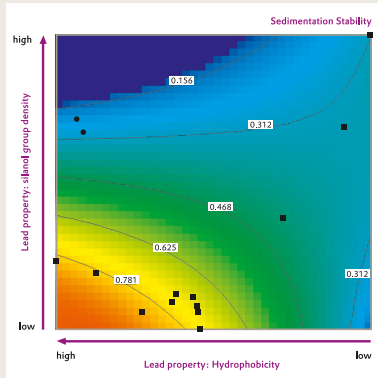

Evonik offers a broad range of surface treated silica products, which are either based on SIPERNAT® precipitated silica or AEROSIL fumed silica. Based on the properties of the hydro- philic starting material and different surface treatment agents applied in the surface treatment process, these products vary in their physico-chemical properties, for example, specific surface area (BET), surface silanol group density, methanol- wettability and C-content'. The two-dimensional diagram shown in Figure 1 was created based on these physico-chemical data. While positioning of a silica type on the x- axis is predominantly influenced by its hydrophobicity (lead property 1), its positioning on the y-axis is mainly determined by its surface silanol group density (lead property 2). Throughout this technical brochure, the silica grades investigated have the same relative position within the square.

Figure 1 Graphic depiction of the physico-chemical properties of the evaluated hydrophobic AEROSIL®- and SIPERNAT®- grades.

- Production and Properties of AEROSIL® R 8200

AEROSIL® R 8200 is produced by the fl ame hydrolysis of SiCl4 (7), as with all AEROSIL® grades. Large quantities of hydrogen chloride are generated and are separated from the fumed silica using special techniques. The new aspect of this process is that the silica's surface is specifi cally modifi ed by an intensive hydrophobization treatment with trimethylsilyl groups and that the silica's thickening effect is reduced to a particularly low level by subsequent treatment processes. An additional advantage for the user is that this is a continuous production process, ensuring quality fl uctuations are reduced to a minimum.

Physico-chemical properties AEROSIL® R 8200, produced by the process described in 3.1, possesses all the advantages of the hydrophobic types of AEROSIL®. Its carbon content, which is a measure of the degree of hydrophobicity, is 2 - 4 % and is higher than that of other hydrophobic silicas. Only AEROSIL® R 812 S has a similar level of hydrophobicity. The high tamped density of AEROSIL® R 8200 (approx. 140 g / l) also deserves special mention. It is significantly higher than that of other fumed silicas, which have tamped densities of approx. 50 g / l. When handled correctly, AEROSIL® R 8200 generates considerably less dust during processing. The high tamped density is also an advantage when incorporating the product into polymers as it considerably reduces the addition time. Based on our experiences, this will lead to a marked increase in productivity during the compounding process and to a greater utilization of the equipment.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- AEROSIL® Silica Improves Mechanical Properties of Silicone Elastomers by Reinforcement

- Furthermore, durability and fatigue resistance are important requirements for the long-term mechanical stability of silicones in a wide range of current and future applications that include damping systems in electric vehicles, soft robotics, artificial muscles and biomedical devices.

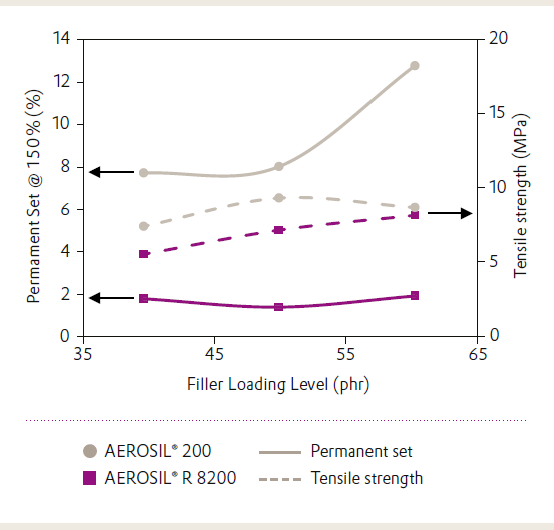

- To improve the fatigue resistance of the silicone elastomers, structure modified hydrophobic fumed silica, AEROSIL® R 8200, ensures a low permanent set, even at high loading levels in combination with good mechanical reinforcement.

Figure 1: Comparison of permanent set and tensile strength of HCR filled by AEROSIL® R 8200 and AEROSIL® 200 at different loading levels

Basics of Fatigue

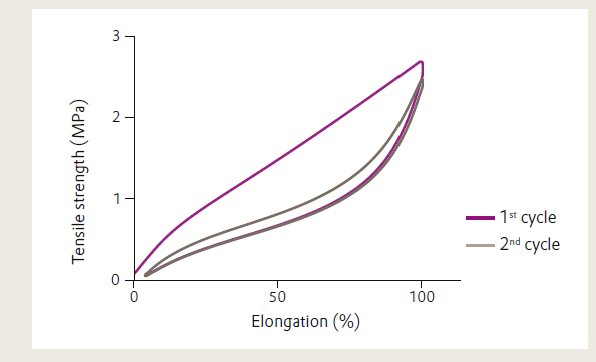

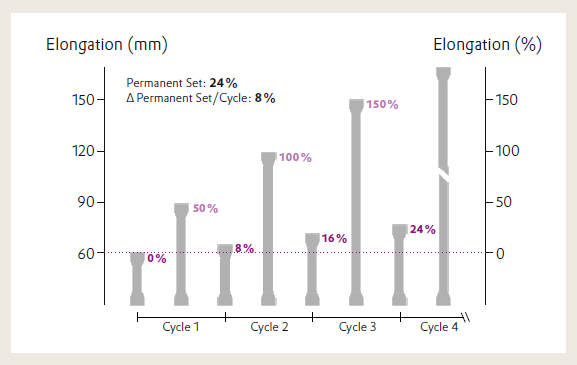

When filler reinforced silicones are extended to a length never experienced before, Mullins stress softening and a permanent set of the elastomer occur as presented in Figures 2 and 3 for a high consistency rubber filled with 25 wt% fumed silica.

Figure 2: describes the Mullins effect in a stress-strain curve for HCR filled with 25 wt% fumed hydrophilic silica. During the initial cycle, the silicone rubber exhibits a specific stress response, upon loading a second time, a loss in the exhibited strength occurs, known as the Mullins effect.

Figure 3: Describes the change in permanent set of the elastomer per loading cycle. The residual elongation remaining, after the initial loading, is known as the permanent set.

Summary

- The structure-modified hydrophobic AEROSIL® R 8200 significantly improves the fatigue resistance of silicones by reducing the permanent set and energy loss, at the same time providing good reinforcement and processability.

- As presented in Figure 1, tensile strength of the compounds filled with AEROSIL® R 8200 increases gradually with higher loading level, preserving a low permanent set. This behavior allows incorporation of AEROSIL® R 8200 to high loading levels for good reinforcement without losing the low permanent set, which is important for fatigue resistance of silicones. In contrast, compounds with AEROSIL® 200 and processing aid, that are commonly applied for the reinforcement of HCR, reveal tensile strength on identical level, but a significantly higher permanent set than AEROSIL® R 8200.

- High fatigue resistance increases the durability and the life-time of silicone components thus, improving their sustainability.

- Influence of AEROSIL® R 8200 in Different Silicone Rubber Systems

Properties in two component RTV silicone rubber

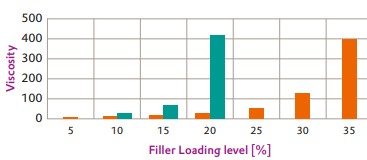

Applications for two component systems can be found in areas such as dental technology, monument preservation and in the rapid prototyping of molded plastic parts, e. g. as used in the automotive industry. The advantage of two component silicone rubber is its easy processing at room temperatures. Its excellent separation effect and precision molding capability are particularly important characteristics. To achieve this, the low viscosity characteristics of the polymer must not be signifi cantly aff ected by the fi ller content which has, at the same time, to impart a high level of mechanical strength to the crosslinked compounds. AEROSIL® R 8200 is the only hydrophobic AEROSIL® grade to satisfy these requirements. Figure 1 illustrates the viscosity increase relative to the addition levels of the two AEROSIL® grades R 8200 and R 812 S, both of which are modifi ed with trimethylsilylgroups. Already, at a loading level of 20 %, the viscosity of the AEROSIL® R 812 S fi lled polymer is 10 times greater than that of the AEROSIL® R 8200 fi lled formulation. Fumed silicas such as AEROSIL® 200 or 300, which have had no treatment whatsoever, would give a comparative viscosity of several thousand Pascal seconds under these circumstances. The low thickening effect of AEROSIL® R 8200 enables high addition levels in two component systems, which in turn have a very positive effect on the mechanical properties of the vulcanized compounds.

Figure 1 Relationship between the viscosity of two component RTV silicone formulations and the filler loadings (AEROSIL® R 8200 , AEROSIL® R 812 S )

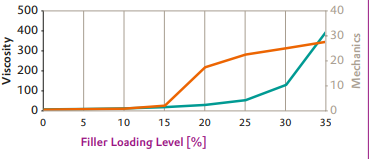

Tear resistance increases sharply with addition levels above 15 %. At this concentration level, a so-called "locking effect" is reached. At higher addition levels a continued but more gradual increase becomes apparent (see Figure 2).

Figure 2 Rheological and mechanical properties of a two component RTV formulation containing AEROSIL® R 8200 at different addition levels.

A comparison between the properties of a two component RTV silicone rubber containing AEROSIL® R 8200 as fi ller with AEROSIL® R 812 S is given in Table 2. Other types of AEROSIL® are not included since they cannot be recommended for two component RTV silicone rubber systems without additional in-situ-hydrophobization because of their pronounced thickening effect.- Sedimentation Stability of Defoamer Formulations

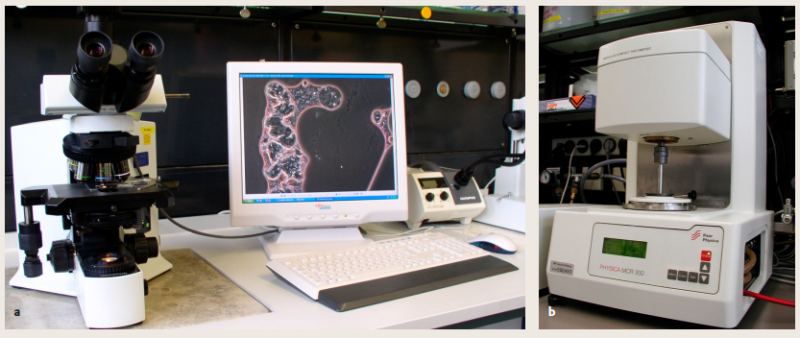

To prepare the model defoamer formulations, 2 weight-% each of the silica products listed above were incorporated in a mixture consisting of polyethersiloxane (38 weight-%, TEGO 5861, Evonik Goldschmidt GmbH and mineral oil (60 weight-%, ONDINA® 913, Shell). For incorporation of the silica we used a rotor-stator system Ultra-Turrax® at 10.000 rpm for 1 minute. The quality of dispersion and the sedimentation stability of the defoamer formulations obtained was recorded at intervals of 7, and 31 days and 6 months by means of a) microscopic evaluation and /or b) rheological measurements (see Figure 2 and 4) and subsequently visual inspection.

Figure 2 Methods used for evaluation of the dispersion and sedimentation stability of the model defoamer formulation a Microscopy for checking the quality of the dispersion b Rheology for viscosity measurements

Figure 3 Sedimentation stability of hydrophobic AEROSIL* and SIPERNAT® containing model defoamer formulations. The higher the number of an isoline, the more stable the model defamer formulation is expected to be against settling. The relative position of the black dots in this and the following figures represent the same silica grades as shown in Figure 1

On the other hand, the rather hydrophobic precipitated silica products SIPERNAT® D 10 and SIPERNAT® D 17, the structure modified fumed silica grades AEROSIL* R 9200 and AEROSIL R 7200, and the slightly hydrophilic AEROSIL* R 816 are located in the upper (green and blue colored) part of the diagram in Figure 3. They are therefore not expected to have sufficient sedimentation stability in the tested model defoamer formulation. Combinations of precipitated and fumed silica may improve the stability of the formulation considerably; however, this is beyond the scope of this brochure and will be explored in the future.

Every black dot represents the same silica grade as shown in Figure 1. The higher the number of an isoline, the more stable the respective model defoamer formulation is expected to be against settling. For example, a silica grade positioned in the red or yellow area means that the model defamer it is based on should have very good or good sedimentation stability. The following hydrophobic AEROSIL* fumed silica products were actually found to have good or very good sedimentation stability:

Packaging & Availability

Storage & Handling

- Shelf Life

- 2 years

- Storage Conditions

Recommend to store the product in closed containers under dry conditions and to protect the material from volatile substances. AEROSIL® R 8200 should be used within 2 years after production.