Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Specific Features

- Addition Curing

- Excellent mechanical properties

- Fast curing at room temperature

- Flowable

- No chemical shrinkage

- Two-component

Applications & Uses

- Cure Method

- Applications

Elastomers for Pad Printing.

- Application Details

Base rubber for making printing pads. ELASTOSIL® RT 623 A/B has been specially designed as a base material for making printing pads. The vulcanizate’s high mechanical strength and long term stability of hardness make ELASTOSIL® RT 623 A/B an ideal base material for producing printing pads with excellent mechanical properties and long service life.

Processing

The platinum catalyst is in component B. A and B components may only be used together if they have the same batch number. To ensure both optimum flow and homogeneity of the material, the components must be stirred thoroughly before they are removed or processed in their containers, in order to uniformly disperse any fillers that might have settled during storage.

Properties

- Catalyst Properties

- Cured Properties

- Uncured Properties

- Properties

- Very good flow

- High reactivity for fast demolding even if large amounts of silicone fluid are added

- Fast and non-shrink cure at room temperature which can be accelerated considerably by the application of heat

- Medium Shore A hardness (approx. 31)

- High tear strength

- Long-term stability of the vulcanizate’s mechanical properties, particularly its hardness

- Note

Cured Properties: After 24 hours at 23°C.

- Dilution Charts

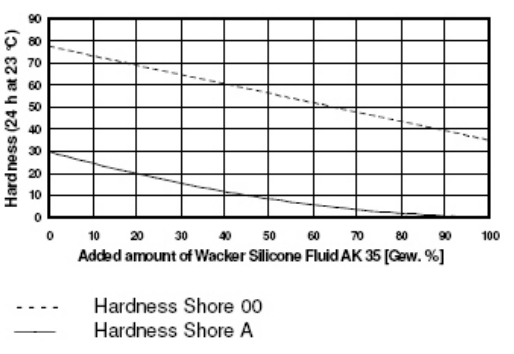

The following table shows the hardness of ELASTOSIL® RT 623 A/B as a function of the added amount of Wacker Silicone Fluid AK 35 for Durometer Types Shore A and Shore 00.

Hardness Shore A/Shore 00

Added amount of Wacker Silicone Fluid AK 35 [wt %] 0 30 50 70 100 120 Shore A 31 14 8 4 1 0 Shore 00 80 64 57 46 34 28

| Value | Units | Test Method / Conditions | |

| Curing Time (tack-free) | 5 | hours | — |

| Dynamic Viscosity (at 23°C) | 10000 | mPa·s | ISO 3219 |

| Mix Ratio (A:B) | 9:1 | parts by weight | — |

| Pot Life (at 23°C, up to 60,000 mPa.s) | 30 | minutes | DIN EN ISO 2555 |

| Value | Units | Test Method / Conditions | |

| Density (in water, at 23°C) | 1.12 | g/cm³ | DIN EN ISO 1183-1 A |

| Elongation (at break) | 700 | % | ISO 37 Type 1 |

| Linear Shrinkage | max. 0.1 | % | — |

| Shore Hardness A | 31 | — | DIN ISO 48-4 |

| Tear Strength | min. 30 | N/mm | ASTM D 624 B |

| Tensile Strength | 7.5 | N/mm² | ISO 37 Type 1 |

| Value | Units | Test Method / Conditions | |

| Density (at 23°C, Componenet A) | 1.14 | g/cm³ | DIN EN ISO 2811-1 |

| Density (at 23°C, Componenet B) | 1.02 | g/cm³ | DIN EN ISO 2811-1 |

| Dynamic Viscosity (Component A, at 23°C, after stirring) | 15000 | mPa·s | ISO 3219 |

| Dynamic Viscosity (Component B, at 23°C, after stirring) | 800 | mPa·s | ISO 3219 |

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Safety Notes

Components of the addition-curing grade ELASTOSIL® RT 623 A/B contain only constituents that over many years have proved to be neither toxic nor aggressive. Special handling precautions are therefore not required, i.e., only the general industrial hygiene regulations apply.

Packaging & Availability

- Country Availability

- Regional Availability