Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Specific Features

- Antistatic

- Condensation-curing

- Fast curing

- Two-component

Applications & Uses

- Applications

- Cure Method

- Plastics & Elastomers End Uses

- Applications

Elastomers for Pad Printing, antistatic behavior.

- Application Details

ELASTOSIL® RT 402 has been particularly designed as a base material for making printing pads. A special feature of ELASTOSIL® RT 402 is that it contains an antistatic additive for fast dissipation of static charge that has built up on the pad surface. This feature is particularly important for printing on highly sensitive electronic parts such as CPUs.

Processing

- ELASTOSIL® RT 402 is exclusively processed with 3 wt % Catalyst T 12, based on the total amount of the mass (rubber base or base plus silicone fluid).

- To ensure homogeneity of the material, the components must be stirred thoroughly before they are removed from or processed in their containers, in order to uniformly disperse any fillers that might have settled during storage.

- It is advisable to thoroughly mix rubber base and fluid before the catalyst is incorporated. When diluting ELASTOSIL® RT 402 with silicone fluid, it is advisable to thoroughly mix rubber base and fluid before the catalyst is incorporated.

Properties

- Catalyst Properties

- Cured Properties

- Uncured Properties

- Properties

- Very good flowability and self-deaeration

- Very low hardness (Shore A approx. 11)

- Good tear strength

- Excellent transfer characteristics for printing inks

- Antistatic finish

- Note

Catalyzed with 3 wt % Catalyst T 12, after 4 days at 23°C / 50 % rel. humidity.

- Dilution Charts

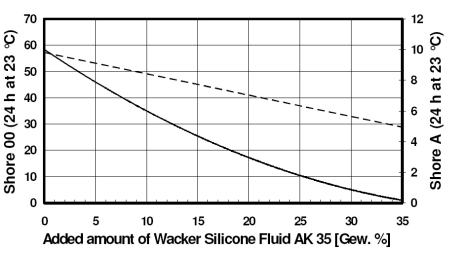

The following table shows the hardness of ELASTOSIL® RT 402 as a function of the added amount of Wacker Silicone Fluid AK 35 for Durometer Types Shore A and Shore 00.

Hardness Shore A/Shore 00

Added amount of Wacker Silicone Fluid AK 35 [wt %] 0 5 10 20 25 35 Shore A 10 8 6 3 2 0 Shore 00 58 53 49 40 36 30

| Value | Units | Test Method / Conditions | |

| Curing Time (tack-free) | 5 | hours | — |

| Dynamic Viscosity (at 23°C) | 13000 | mPa·s | ISO 3219 |

| Pot Life (at 60.0 mPa·s) | 75 - 75 | minutes | — |

| Value | Units | Test Method / Conditions | |

| Density (in water, at 23°C) | 1.28 | g/cm³ | ISO 2781 |

| Elongation (at break) | 350 | % | ISO 37 |

| Shore Hardness A | 11 | — | ISO 868 |

| Tear Strength | min. 3 | N/mm | ASTM D 624 B |

| Tensile Strength | 2 | N/mm² | ISO 37 |

| Value | Units | Test Method / Conditions | |

| Density (at 20°C) | approx. 1.29 | g/cm³ | — |

| Dynamic Viscosity (at 23°C) | approx. 15000 | mPa·s | Brookfield |

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Safety Notes

Being a condensation-curing silicone rubber, ELASTOSIL® RT 402 contains only constituents that over many years have proved to be neither toxic nor aggressive. Special handling precautions are therefore not required, i.e., only the general industrial hygiene regulations apply. Catalyst T 12 contains a tetraorganotin compound, is flammable (flash point > 50 °C) and may cause irritation in contact with the eyes and skin. Appropriate protective measures are required.

Packaging & Availability

- Country Availability

- Regional Availability