Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Product Type

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- CAS No.

- 78-08-0

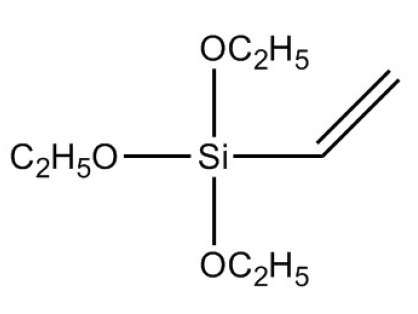

- Molecular formula

- C₈H₁₈O₃Si

- EC No.

- 201-081-7

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Application pH Range

- approx. 4 - 5

- Applications

- Plastic Crosslinking

- Plastic Additives

- Application Details

General processing information:

GENIOSIL® GF 56 dissolves readily in standard organic solvents, but is practically insoluble in neutral water. GENIOSIL® GF 56 hydrolyzes in acidified water (pH approx. 4 - 5) to silanols, the diluted solutions of which remain stable for some time.

GENIOSIL® GF 56 as a polymer building block

- To incorporate GENIOSIL® GF 56 into organic polymers, it is added as a co-monomer - along with typically used monomers and free-radical initiators (diazo compounds or peroxides) - during production of the solution or emulsion polymer.

- Grafting of GENIOSIL® GF 56 to polyolefins, such as LDPE and HDPE, is usually effected via peroxide-initiated reactive extrusion. Polyolefins grafted with GENIOSIL® GF 56 are moisture-cured following molding.

GENIOSIL® GF 56 as a coupling agent

- Fillers are treated either with pure GENIOSIL® GF 56 or a solution thereof. It may be necessary to pretreat the substrate with water and/or a catalyst. Subsequent binding of the modified filler to organic polymers is preferably effected via grafting during extrusion.

- Used as a primer, GENIOSIL® GF 56 is applied to an inorganic substrate, such as a metal surface, in the form of an aqueous or alcoholic solution. After GENIOSIL® GF 56 has dried and bonded to the surface, an organic coating may be applied using a standard technique.

- GENIOSIL® GF 56 is used in the production of silane-modified polymers that serve as binders in paints and adhesives. GENIOSIL® GF 56 is also used in the manufacture of pipes and cables made of silane-crosslinked polyethylene (PE-Xb).

- In addition, GENIOSIL® GF 56 serves as an adhesion promoter in primers and coatings, and is used in the production of organically modified fillers for cable insulation.

Properties

- Color

- Insoluble in

- Water

- Soluble in

- Standard organic solvents

- Typical Properties

- Properties

- The use of GENIOSIL® GF 56 as a co-monomer in polymers results in binders which, among other advantages, exhibit much improved wet scrub resistance and abrasion resistance thanks to crosslinking and better adhesion to the substrate. Silane-modified thermoplastics obtained by grafting with GENIOSIL® GF 56 can be processed further using standard techniques.

- On exposure to moisture (e.g. water bath, climatic chamber), the silyl groups condense (ethanol is released) and function as crosslinking and/or adhesion points. By treating fillers with GENIOSIL® GF 56, mineral-filled polymers can be obtained which exhibit improved mechanical and electrical properties.

- In addition, the particles are rendered strongly water repellent, which results in improved filler dispersibility and thus facilitates processing. Organic surface coatings will adhere more strongly to inorganic substrates that have been treated with GENIOSIL® GF 56. As a result, these coatings demonstrate markedly greater scratch resistance and resistance to chemicals.

| Value | Units | Test Method / Conditions | |

| Boiling Point (at 1013 hPa) | 158 | °C | — |

| Molecular Weight | 190.31 | g/mol | — |

| Density (at 25°C) | 0.91 | g/cm³ | DIN 51757 |

| Flash Point | 37 | °C | ISO 3679 |

| Hydrolyzable Chloride (as HCI) | max. 10 | mg/kg | — |

| Ignition Temperature | 265 | °C | DIN 51794 |

| Purity | min. 98 | % | Gas Chromatography |

| Refractive Index (at 25°C) | 1.397 | — | DIN 51423 |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Packaging & Availability

- Country Availability

- Packaging Type

- Regional Availability

- Packaging Information

- 25 kg can

- 180 kg drum

- 800 kg IBC