Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- CAS No.

- 2768-02-7

- EC No.

- 220-449-8

- Technologies

- Product Families

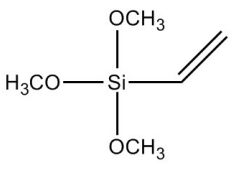

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Use Level

- 1 - 2 %

- Applications

- Marine & Protective Coatings

- Plastic Crosslinking

- Industrial Coatings

- Plastic Additives

- Application Details

GENIOSIL® XL 10 is used in the production of pipes and cables made of silane-crosslinked polyethylene (PE-Xb), as a water scavenger during the production of silane-crosslinking adhesive and sealant formulations, and as co-monomers in the production of silane-modified binders for surface coatings.

- Grafting of GENIOSIL® XL 10 - The radical grafting of GENIOSIL® XL 10 to polyolefins, such as HDPE and LDPE, is typically effected via reactive extrusion, using peroxides as catalysts. Usually, 1-2 wt % GENIOSIL® XL 10 is required, expressed in terms of the polyolefin. Polyolefins grafted with GENIOSIL® XL 10 are moisture-cured after molding.

- GENIOSIL® XL 10 as an additive in silane-crosslinking formulations - In silane-crosslinking formulations, (e.g. silane-terminated polyethers , polyurethanes or polysiloxanes), GENIOSIL® XL 10 is mixed into the formulation as an additive to prevent premature crosslinking due to trace moisture. Processing is effected by means of standard mixing methods (e.g. paddle agitator, dissolver, kneader). GENIOSIL® XL 10 may be added before or during incorporation of the reactive polymer. The amount added will depend on the water content and pretreatment of the components.

- GENIOSIL® XL 10 as a co-monomer in polymer dispersions - To incorporate GENIOSIL® XL 10 in organic polymer dispersions by way of co-polymerization, it is added as as comonomer - along with typically used monomers (e.g. ethylene, vinyl acetate, styrene, acrylate) and freeradical initiators (diazo compounds or peroxides) - during production of the emulsion polymer.

Properties

- Appearance

- Clear colorless liquid

- Odor

- Characteristic odor

- Typical Properties

- Properties

- Pipes and cables produced from silane-crosslinked polyethylene (PE-Xb) using GENIOSIL® XL 10 are more resistant to heat and weathering than products made from non-crosslinked polyethylene.

- They also have improved electrical properties. The storage stability is greatly enhanced in formulations of silane-crosslinking adhesives and sealants.

- Use of GENIOSIL® XL 10 as a co-monomer in polymer dispersions results in binders which exhibit much improved wet scrub resistance and higher abrasion resistance thanks to crosslinking and improved adhesion to the substrate.

| Value | Units | Test Method / Conditions | |

| Boiling Point (at 1013 hPa) | 122 | °C | — |

| Density (at 25°C) | 0.97 | g/cm³ | DIN 51757 |

| Dimer Content | max. 0.3 | % | Gas Chromatography |

| Dynamic Viscosity (at 25°C) | 0.6 | mPa·s | DIN 51562 |

| Flash Point | 25 | °C | ISO 13736 |

| Hydrolyzable Chloride (as HCI) | max. 10 | mg/kg | — |

| Ignition Temperature | 240 | °C | DIN 51794 |

| Methanol Content | max. 0.3 | % | Gas Chromatography |

| Purity | min. 99 | % | — |

| Refractive Index (at 25°C) | 1.391 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Packaging Type

- Regional Availability

- Packaging Information

- 25 kg can

- 180 kg drum

- 195 kg drum